Electrically erasable molecular base organic electric bistable film device and its producing technology

A thin-film device and manufacturing process technology, which is applied in the field of molecular-based electric bistable thin film devices and its manufacturing process, can solve the problems of few times of erasing and writing, small contrast between the two states, and difficulty in erasing and writing, and achieve a large number of switching times , the effect of large state contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The basic structure and performance of the present invention will be described below by taking IMCN as an example.

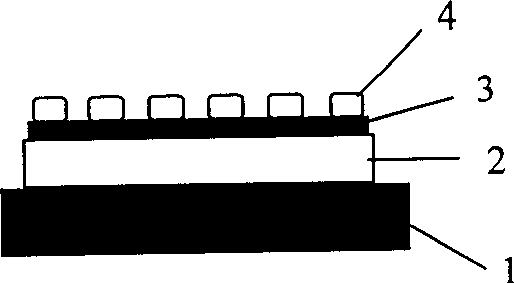

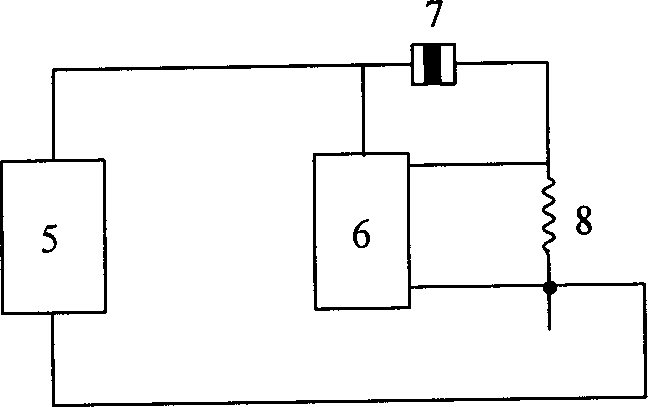

[0040] On the clean slide surface, make a layer of Ag film with vacuum thermal evaporation method as the bottom electrode, then vapor-deposit a layer of thickness and be 80-120 nanometer IMCN, vapor-deposit many Al spots on the organic film again as the top electrode ( Each Al spot is equivalent to a top electrode, and the area of each top electrode is 0.05-2 square millimeters), thus a kind of thin film device Ag-IMCN-Al is obtained.

[0041] The electrical bistable characteristics of the thin film device Ag-IMCN-Al were measured, and the results are as follows:

[0042] The initial resistance of the thin film device is greater than 20 megohms. After turning into a low resistance state, the resistance value is 20-100 ohms, and after returning to a high resistance state, the resistance value is 10 kohms to 5 megohms, and the contrast between the two st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com