Absorption process for directly preparing dimethyl ether and methanol water solution from synthetic raw material gas

A methanol aqueous solution and dimethyl ether technology, which is applied in the preparation of ether from alkylene oxide, ether preparation, organic chemistry, etc., can solve the problems of high operating costs, achieve the effects of reducing rectification energy consumption, improving utilization rate, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

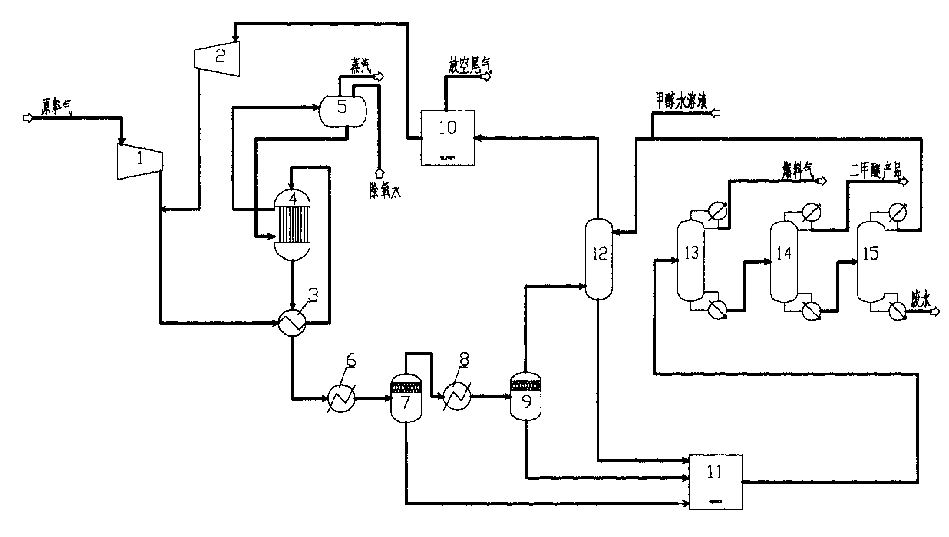

[0024] Adopt attached figure 1 Shown is the direct preparation of dimethyl ether methanol aqueous solution absorption process flow from synthetic raw material gas, the raw material gas (H 2 +CO>50%, the rest is CO 2 , N 2 , Ar, CH 4 , O 2 ) Compressed by compressor 1 to 3.0~7.0MPa and mixed with the circulating gas from the circulating gas compressor 2, it enters the heat exchanger 3, exchanges heat with the synthesis gas from the reactor, and then enters the synthesis reactor 4. (Copper-based dimethyl ether synthesis catalyst produced by Zhejiang University or copper-based synthesis dimethyl ether catalyst produced by Dalian Institute of Chemical Physics) In the isothermal reactor, at a pressure of 3.0~7.0MPa and a temperature of 180-320℃, hydrogen and Carbon monoxide reacts to produce dimethyl ether. The hot synthesis gas from the reactor first exchanges heat with the raw material gas and then enters the cooler 6 to cool to 40°C, and then passes through the condenser 8 to cool t...

Embodiment 2

[0028] The demonstration test device of a chemical fertilizer plant uses the same process and equipment as in Example 1, and the synthesis reaction conditions are the same as in Example 1. The outlet temperature of the dimethyl ether condenser is 10°C. A methanol aqueous solution with a concentration of 95% is used as the absorbent, and the volume ratio of methanol aqueous solution / syngas is 0.01.

[0029] In the pre-rectification tower, under the operating conditions of pressure 1.0~2.0MPa, bottom temperature 60-160℃, and top condenser temperature -30~10℃, the solubility in dimethyl ether solution can be well reduced The gas is separated from the dimethyl ether.

[0030]In the main distillation tower, the concentration of dimethyl ether at the top of the tower can reach above 99.5% under the operating conditions of a pressure of 0.3-1.0 MPa, a temperature of the bottom of the tower 60-200°C, and a temperature of the condenser at the top of the tower 0-45°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com