In-situ analyzer of gas pollutants

An on-site analysis, micro-quantity technology, applied in the direction of measuring devices, sampling devices, analysis materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

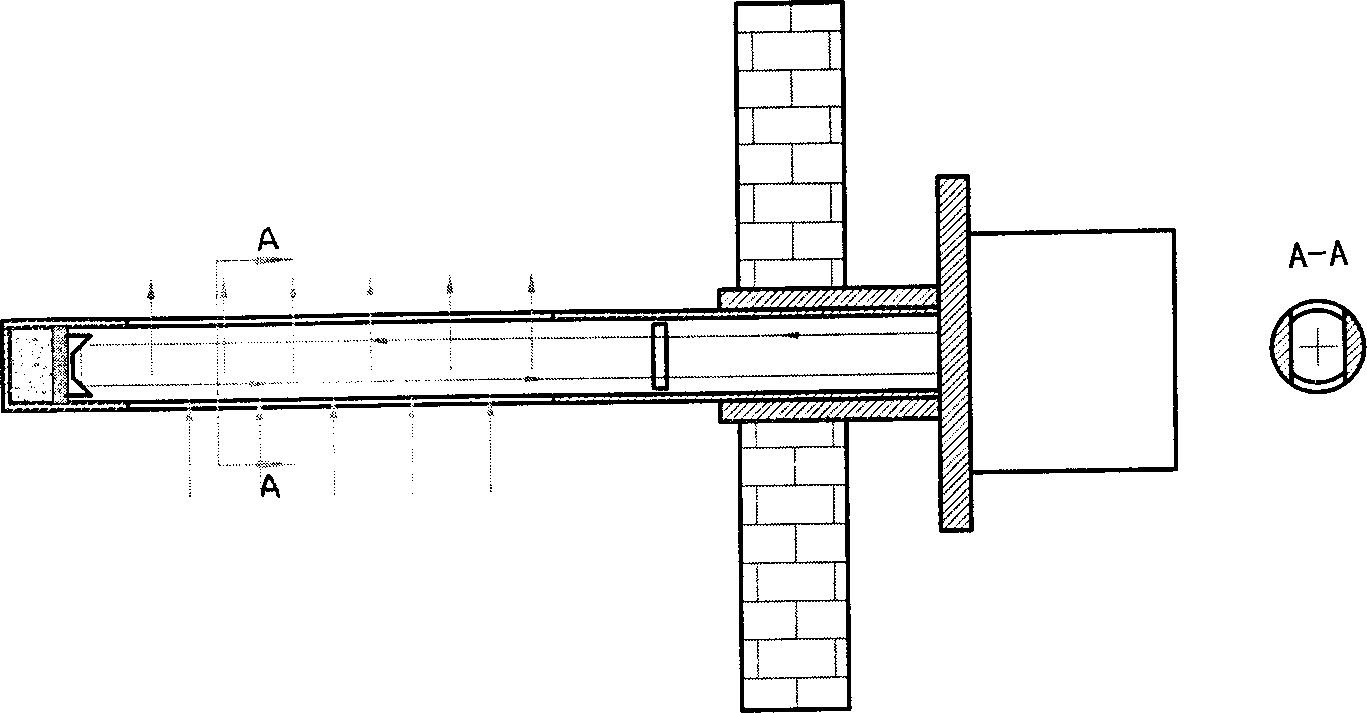

[0019] Refer below Figure 5 The micro-extraction on-site analysis device will be described in detail.

[0020] The on-site micro extraction analysis device of the present invention includes a mirror 60 , a filter set 58 , an infrared light source 59 , an infrared detector 62 , a lens 61 and an optical absorption cavity 54 . The use of these components belongs to common knowledge in the technical field, so their description is omitted.

[0021] The present invention is characterized in that it also includes: a coarse filter 51, a fine filter 52 and a fine filter 53 connected in sequence at the inlet end of the optical absorption cavity 54; a critical air extraction hole 55 arranged on the wall of the optical absorption cavity 54; And a vacuum pump 56, through the critical pumping holes 55 arranged on the tube wall of the optical absorption cavity 54 to extract the gas in the optical absorption cavity 54.

[0022] Calibration gas pipeline 57 is used for calibration (belonging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com