Contact component and its manufacture and probe contact assembly using the contact component

A technology for contacting components and contacting components, which is applied to contact components, measuring leads/probes, components of connecting devices, etc., can solve problems such as inconsistent quality, and achieve the effects of low cost, long life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Detailed description of the preferred embodiment

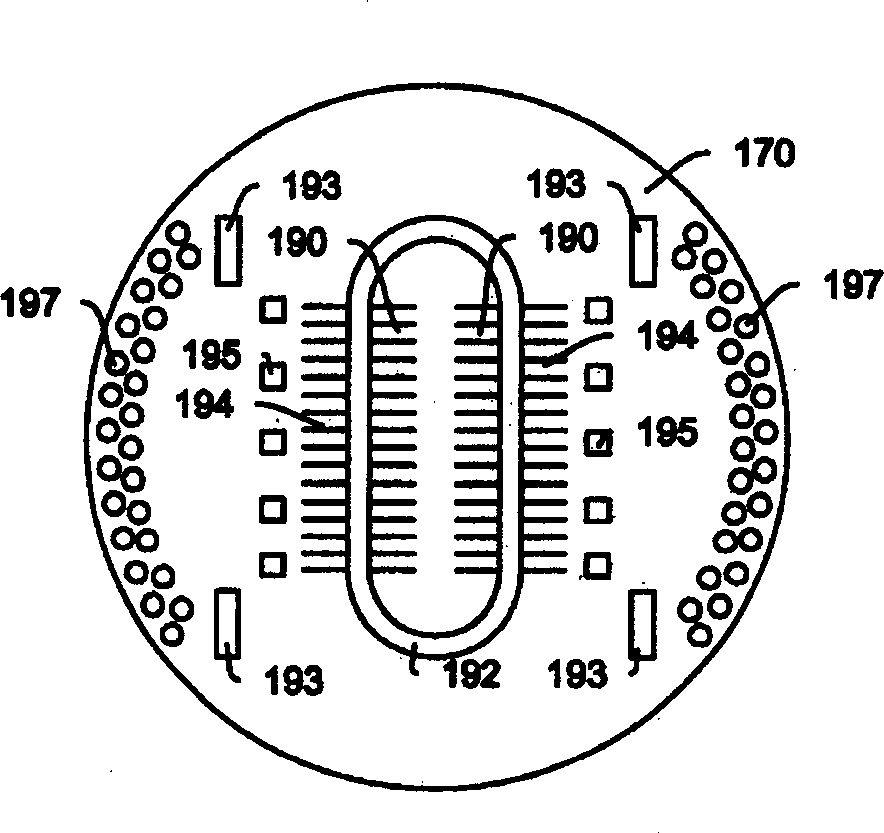

[0086] Figure 5-7 An example of the contact member of the present invention is shown. Each contact member is constituted by a contact substrate 20 and contacts 30 . exist Figure 5 example, each contactor 30 1 Extending substantially in the vertical direction, and being formed: a base, this base is connected to contact substrate 20; A contact point, preferably pointed; A contact spring acts.

[0087] exist Figure 6 example, each contactor 30 2 Extending substantially in the vertical direction, and being formed: a base, is connected with contact substrate 20; A contact point, it is divided into two or more points, and is preferably pointed; And a base and contact point The zigzag part between them acts as a contact spring.

[0088] exist Figure 7 example, each contactor 30 3 Extending substantially in the vertical direction, having a hook shape, and being formed: a base, is connected with con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com