Measuring and controlling method of moisture in sintered mixture material

A technology of sintering mixture and measurement and control method, which is applied in the direction of material analysis, measuring device, and analysis of materials through optical means, which can solve the problems affecting the stable production, unable to solve the problems of measurement and control of water addition for hot-returning sintering, moisture fluctuations, etc. problems, to achieve significant technological progress, eliminate fluctuations, and improve utilization coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

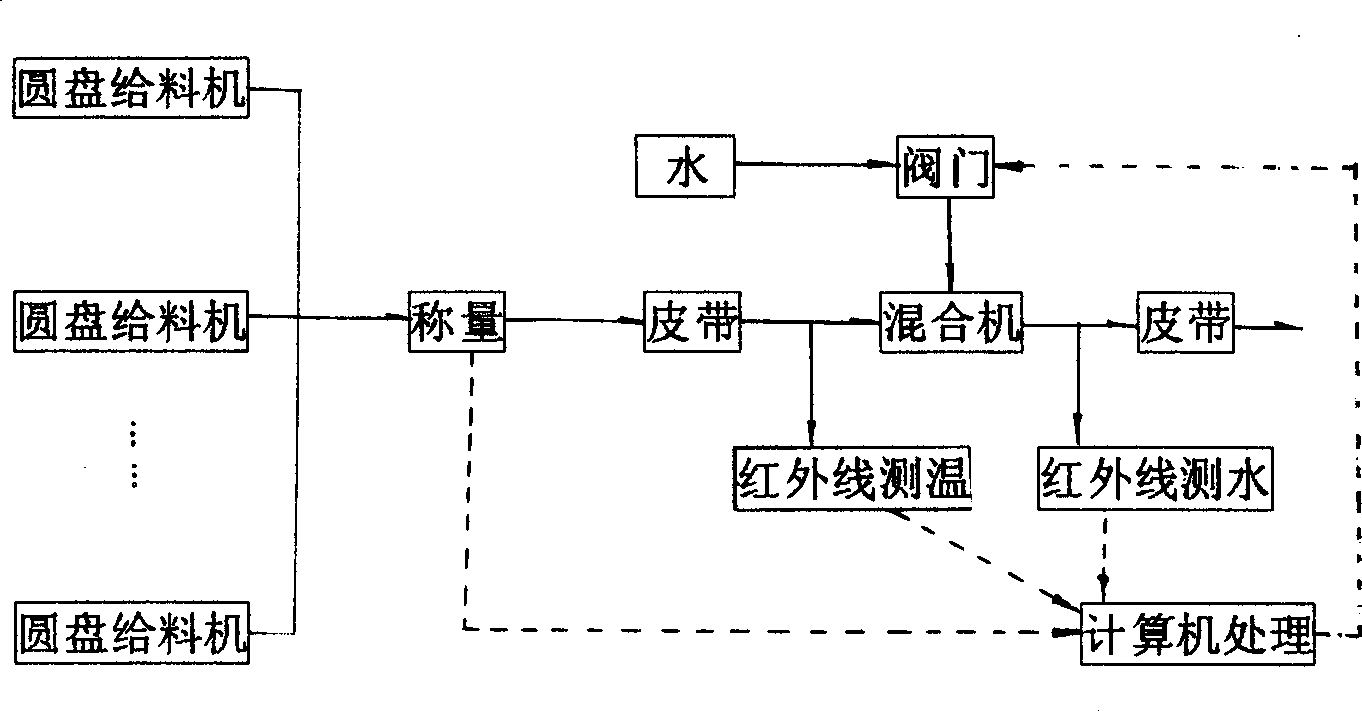

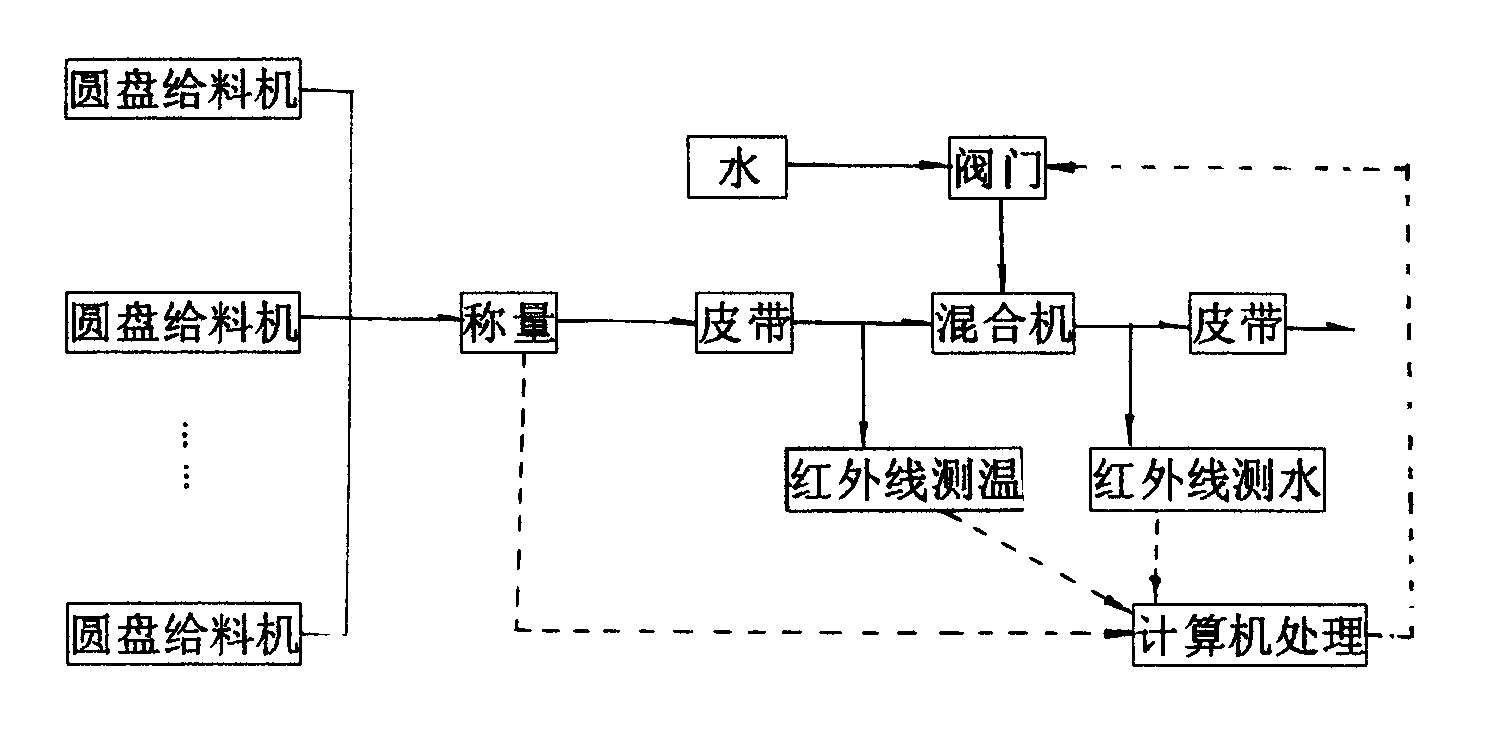

[0012] refer to figure 1 , hot returned ore and other sintering raw materials are weighed by the disc feeder and impact flowmeter, and sent to the mixer by the belt conveyor. After mixing with water, they are sent to the pelletizer by the belt conveyor to make pellets. An infrared thermometer is installed in front of the mixer to measure the temperature of hot ore return before adding to the mixer. In order to increase the measurement accuracy, multi-point measurement can be carried out, and the average value can be taken. Send the hot ore return temperature, dosage and other mixed raw material weight and water weight data sent into the mixer to the computer processing system, and calculate the set value of the water addition amount of the mixer according to the target moisture content of the mixture, and by The control loop drives the actuator to adjust the opening of the water adding valve to add water to the mixer, and then compares the moisture content measured by the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com