Standpipe inlet for enhancing particulate solids circulation for petrochemical and other processes

A standpipe, particle technology, used in chemical instruments and methods, petroleum industry, chemical/physical processes, etc., can solve problems such as air consumption, air bubble inhalation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

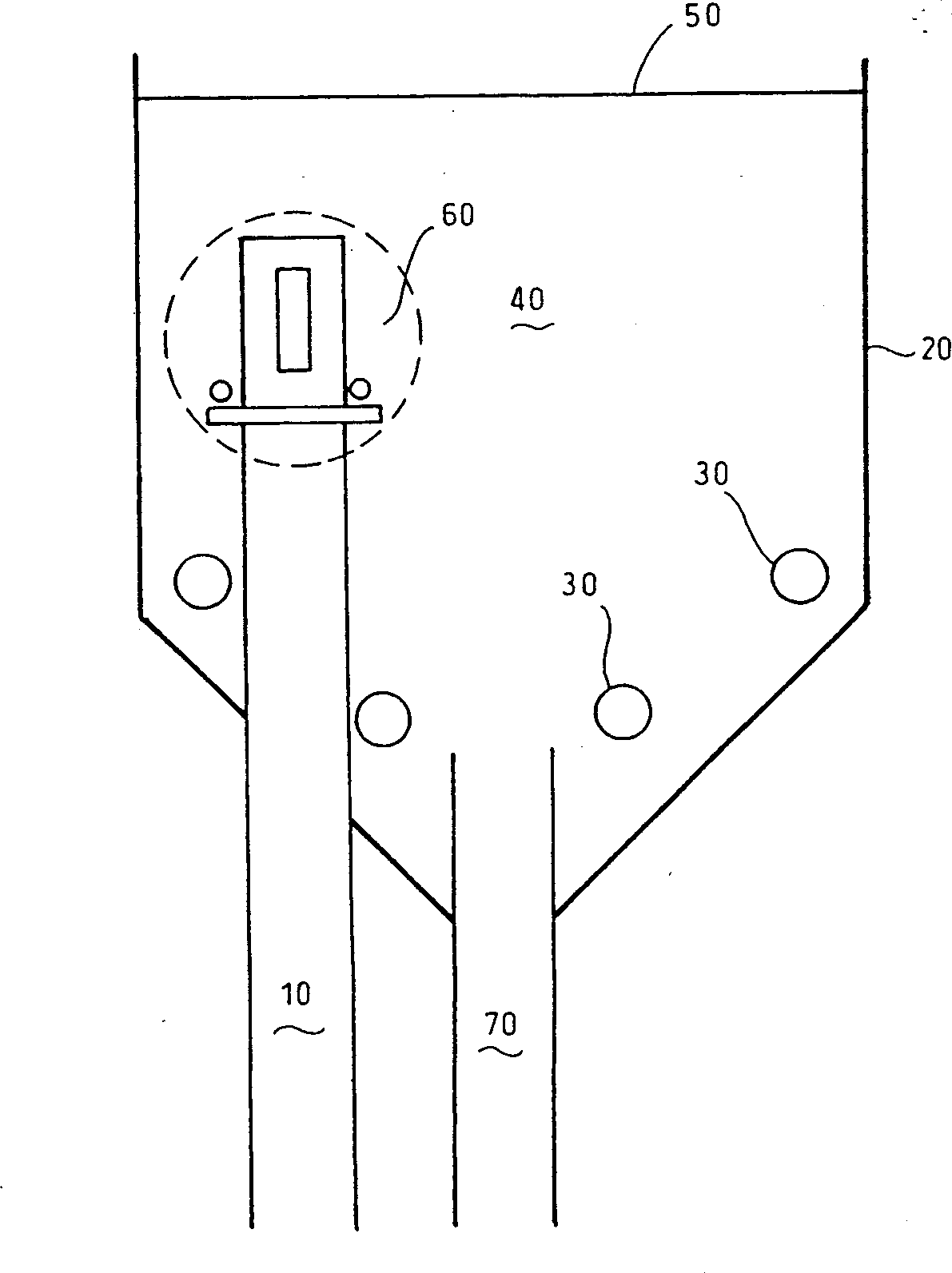

[0018] Reference figure 1 , figure 1 In accordance with the present invention, a cross-sectional view of the lower portion of a conventional regenerator vessel 20 of an FCC unit, wherein the FCC unit is provided with a regenerator standpipe 10 including an inlet portion 60 for sucking in the regenerated catalyst. The spent catalyst is transported from the stripper (not shown) through a conventional residual catalyst delivery pipe 70 and enters the regenerator 20. In the regenerator 20, the coke deposited on the catalyst is transported by the main air grille. The air burns away. The air from the grill 30 and the formed combustion gas rise through the regenerator so that the catalyst in the fluidized bed 40 is fluidized. The combustion gas and the entrained regenerated catalyst are separated by a cyclone (not shown) in the upper part of the regenerator. The combustion gas is discharged from the upper part of the regenerator, and the regenerated catalyst separated by the cyclone (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com