Kaolin/TiO2 nanotube composite particle electrorheological fluid materials

A nanocomposite material and nanotube composite technology, which is applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of easy settling, narrow working temperature range and low mechanical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

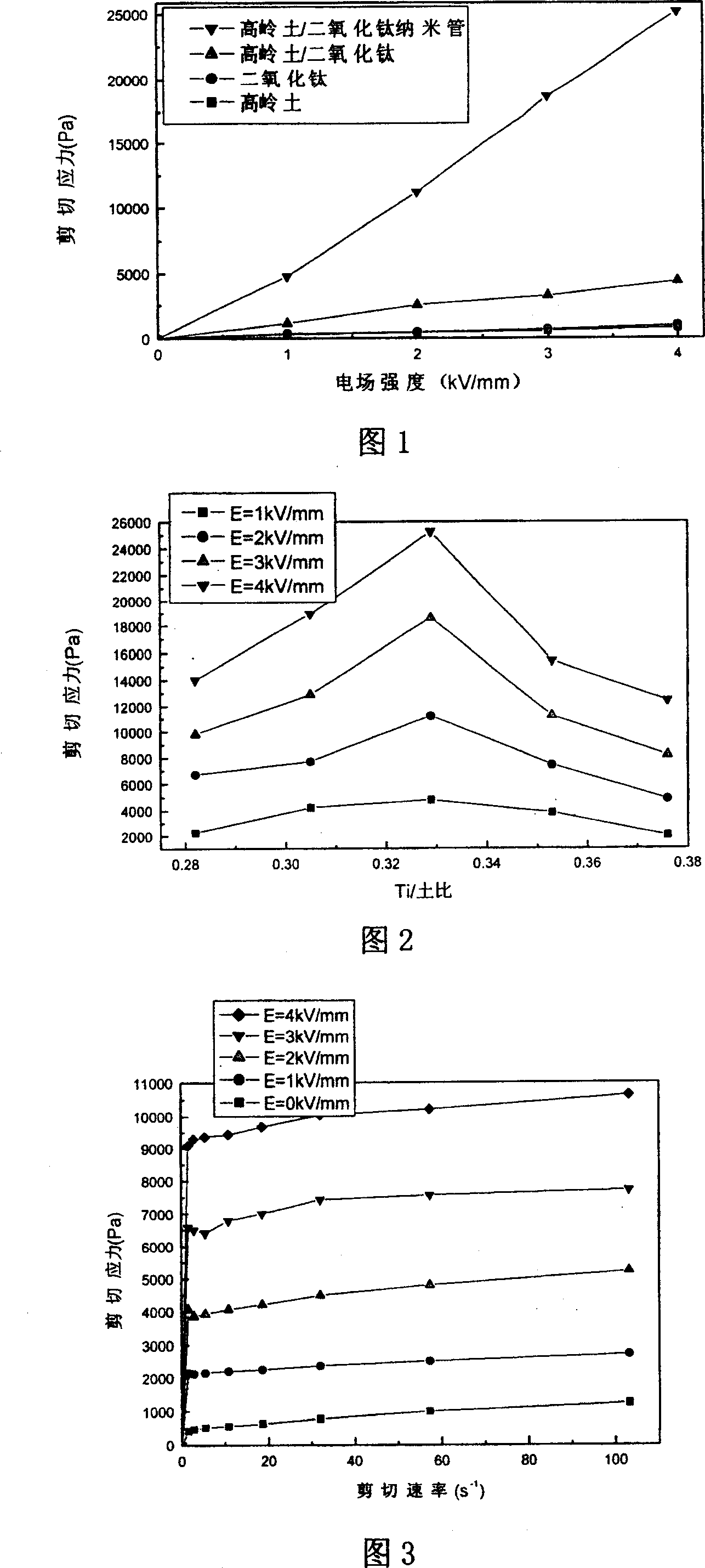

Embodiment 1

[0010] Example 1: firstly add 6g of kaolin to 60ml of absolute ethanol, fully stir at room temperature for 3 hours, at the same time mix 14ml of butyl titanate with 14ml of absolute ethanol, and drop it under the condition of stirring into the ethanol suspension of kaolin, and further fully stirred for 5 hours. At this time, the Ti / soil ratio was 0.329; finally, a certain amount of absolute ethanol containing a small amount of secondary deionized water was added dropwise, and the stirring was continued for 6 hours, and then the system After standing overnight, an opaque gel can be obtained; the gel is then dried at 80°C for 4 hours and at 90°C for 2 hours. After grinding, kaolin / titanium oxide-coated composite particles can be obtained, and then calcined at 200°C for 1 hour, 400°C for 1 hour, and 550°C for 2 hours to obtain kaolin / TiO 2 nanocomposite particles. Then add 400ml 10M NaOH solution to the Teflon bottle, after heating to 120°C, slowly add the aforementioned kaolin / ...

Embodiment 2

[0011] Example 2: first add 6g of kaolin to 60ml of absolute ethanol, fully stir at room temperature for 3 hours, at the same time mix 12ml of butyl titanate with 12ml of absolute ethanol, and drop it into the into the ethanol suspension of kaolin, further fully stirred for 5 hours, and at this time the Ti / soil ratio was 0.282; finally a certain amount of absolute ethanol containing a small amount of secondary deionized water was added dropwise, continued to stir for 6 hours, and then the system was statically After leaving overnight, an opaque gel can be obtained; the gel is then dried at 80°C for 4 hours and at 90°C for 2 hours. After grinding, kaolin / titanium oxide-coated composite particles can be obtained, and then calcined at 200°C for 1 hour, 400°C for 1 hour, and 550°C for 2 hours to obtain kaolin / TiO 2 nanocomposite particles. Then add 400ml 10M NaOH solution to the Teflon bottle, after heating to 120°C, slowly add the aforementioned kaolin / TiO 2 The nanocomposite p...

Embodiment 3

[0012] Example 3: firstly add 6g of kaolin to 13ml of absolute ethanol, fully stir at room temperature for 3 hours, at the same time mix 12ml of butyl titanate with 12ml of absolute ethanol, and drop it into the into the ethanol suspension of kaolin, further fully stirred for 5 hours, and now the Ti / soil ratio was 0.305; finally a certain amount of absolute ethanol containing a small amount of secondary deionized water was added dropwise, and the stirring was continued for 6 hours, and then the system was statically After leaving overnight, an opaque gel can be obtained; the gel is then dried at 80°C for 4 hours and at 90°C for 2 hours. After grinding, kaolin / titanium oxide-coated composite particles can be obtained, and then calcined at 200°C for 1 hour, 400°C for 1 hour, and 550°C for 2 hours to obtain kaolin / TiO 2 nanocomposite particles. Then add 400ml 10M NaOH solution to the Teflon bottle, after heating to 120°C, slowly add the aforementioned kaolin / TiO 2 The nanocompo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com