Valveless micro-pump and packaging method thereof

A micropump and pump body technology, which is applied in the packaging field of valveless micropumps, can solve problems such as inability to realize mass production, poor reliability, and difficult sealing, and achieve the effects of stable operation, high reliability, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, the present invention will be described in more detail with an example in conjunction with the accompanying drawings:

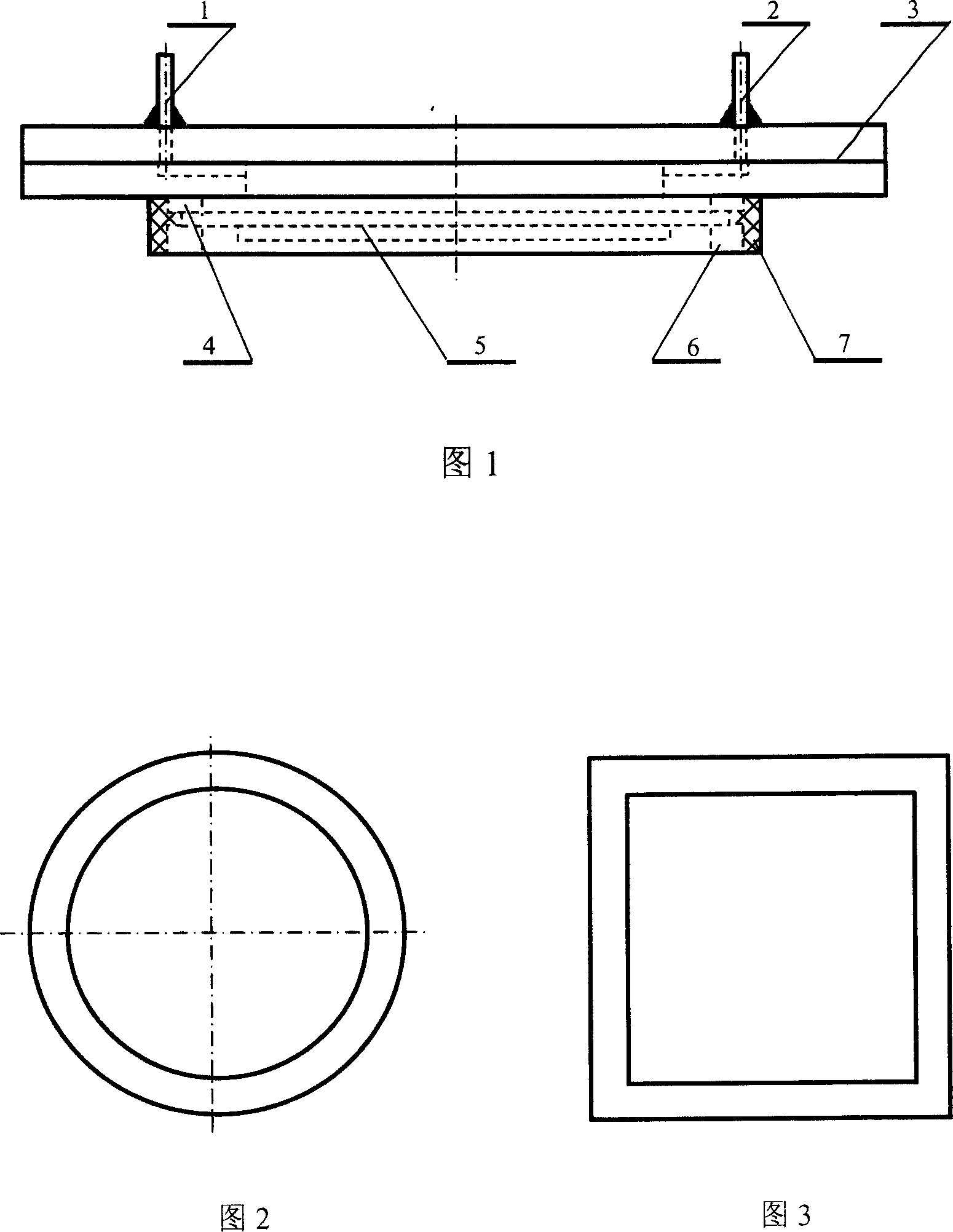

[0012] With reference to Figure 1, the composition of the valveless micropump includes a pump body 3 with an input port 1 and an output port 2 on the pump body. It also includes a piezoelectric ceramic buzzer 5. There is a concentric annular sealing elastic gasket 4 between the pump body and the piezoelectric ceramic buzzer. At the same time, referring to Figures 2 and 3, the shape of the annular sealing elastic gasket matches the shape of the pump cavity and the piezoelectric ceramic buzzer. , Can be round ring, rectangular ring, etc. A metal ring 6 is concentrically arranged on the piezoelectric ceramic buzzer, and a sealing adhesive resin glue 7 is arranged outside the annular sealing elastic pad, the piezoelectric ceramic buzzer and the metal ring.

[0013] The product of the present invention is packaged in such a way to make a valveless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com