Discontinuous power supply full-automatic controlling method and apparatus for motor of beam-pumping unit

A technology of intermittent power supply and motor, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problem of different operation modes of intermittent power supply, and achieve the effect of solving the problem of speed out of control and solving the current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

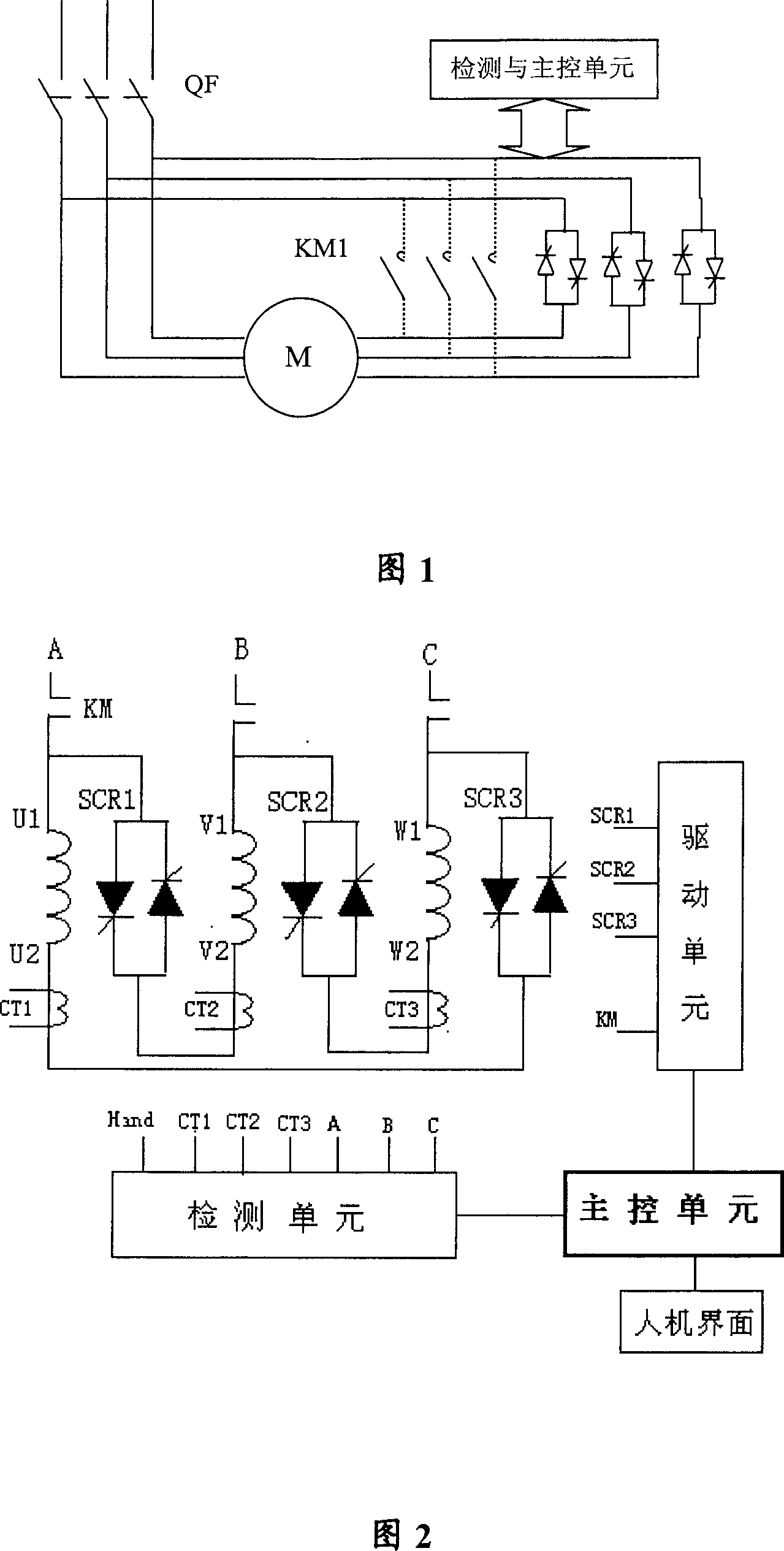

[0036] Please refer to Fig. 1. Fig. 1 is an electrical main circuit diagram of the automatic control device for the intermittent power consumption of the motor of the beam pumping unit. It is controlled by the contactor when the power supply is continuous, and it is controlled by the silicon controlled rectifier when the power supply is intermittent.

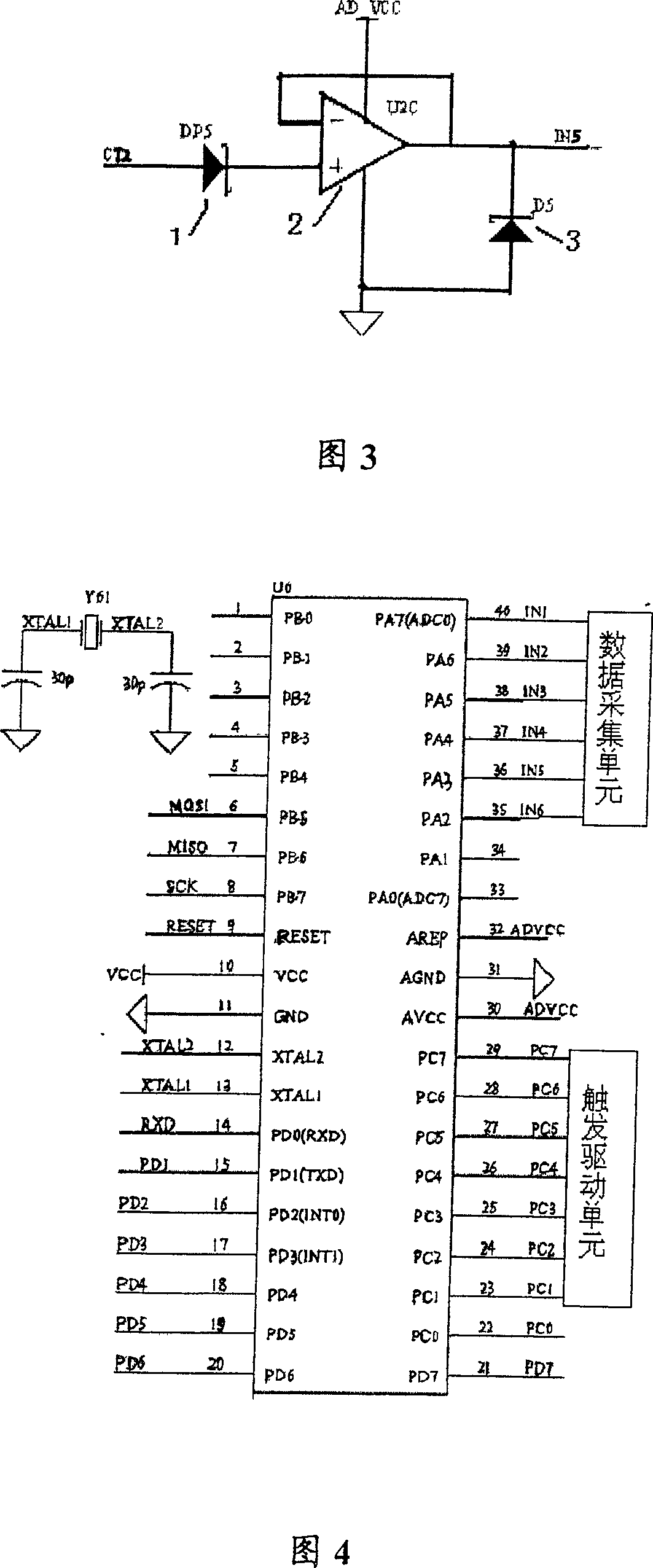

[0037] Please refer to Fig. 2, Fig. 6, Fig. 7, Fig. 2 is the electrical principle diagram of automatic control device of the present invention, Fig. 6 is the electrical principle block diagram of automatic control device, Fig. 7 is the circuit principle block diagram of preferred embodiment of the present invention. The current sensors CT1, CT2, and CT3 are inductively connected to the three-phase power supply loop, and the voltage sensors T1, T2, and T3 are directly connected to the power supply loop to collect the instantaneous values of the working current i and the working voltage u when the motor is continuously powered; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com