Hydraulic mounting machine of oil cylinder

A technology for installing machines and oil cylinders, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of difficult installation, high repair rate and high application cost, reduce the damage rate of seals, ensure high coaxiality, and has a simple and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

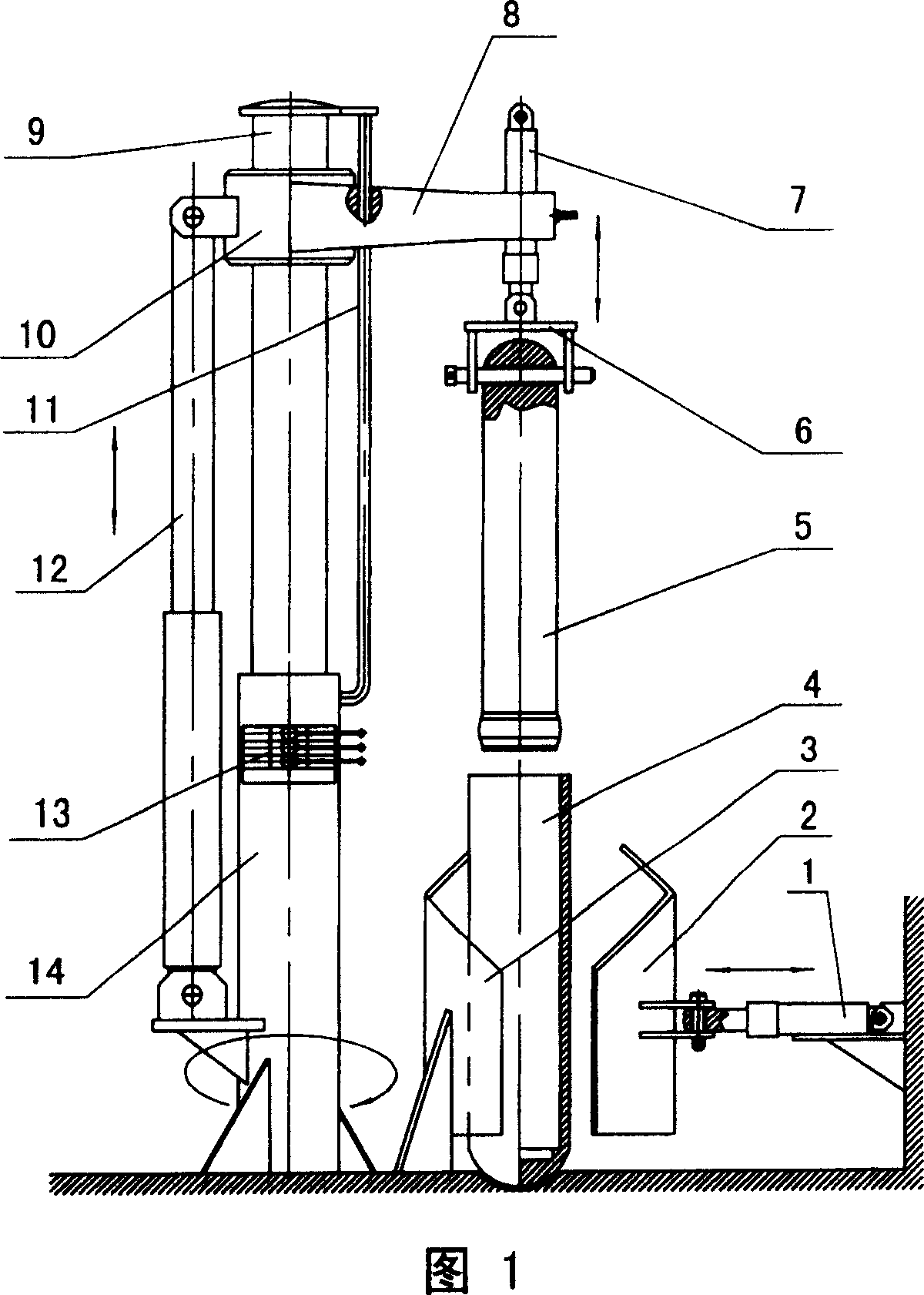

[0014] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

[0015] As shown in the figure, in the cylinder hydraulic installation machine of the present invention, a guide sleeve shaft 9 is provided on the rotatable frame 14, and the guide sleeve 10 on the guide sleeve shaft 9 is connected to the piston rod of the lifting large oil cylinder 12, and the guide sleeve 10 is provided with a guide sleeve moving positioning shaft 11, and the positioning shaft 11 is fixed on the frame 14 parallel to the guide sleeve shaft 9. The large oil cylinder 12 is arranged on the frame 14, and the guide sleeve 10 is provided with a boom 8 and a boom 8. A lifting small oil cylinder 7 is arranged on the top, and the lower end of the piston rod of the small oil cylinder 7 is provided with an oil cylinder piston rod cross coupling joint 6, and a cylinder barrel clamping and fixing device composed of splints 2 and 3 is corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com