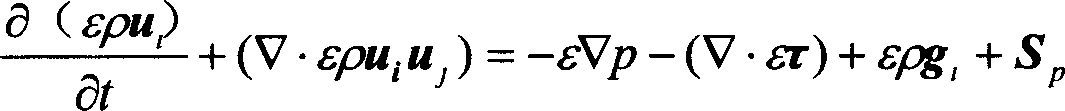

Method for modelling mixed material fluid-solid two-phase flow in mixing cylinder of concrete mixer car

A technology for a concrete mixer truck and a modeling method, which is applied in chemical instruments and methods, cement mixing devices, clay preparation devices, etc., can solve the problems of high cost and long design cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be further described below with reference to the drawings and examples.

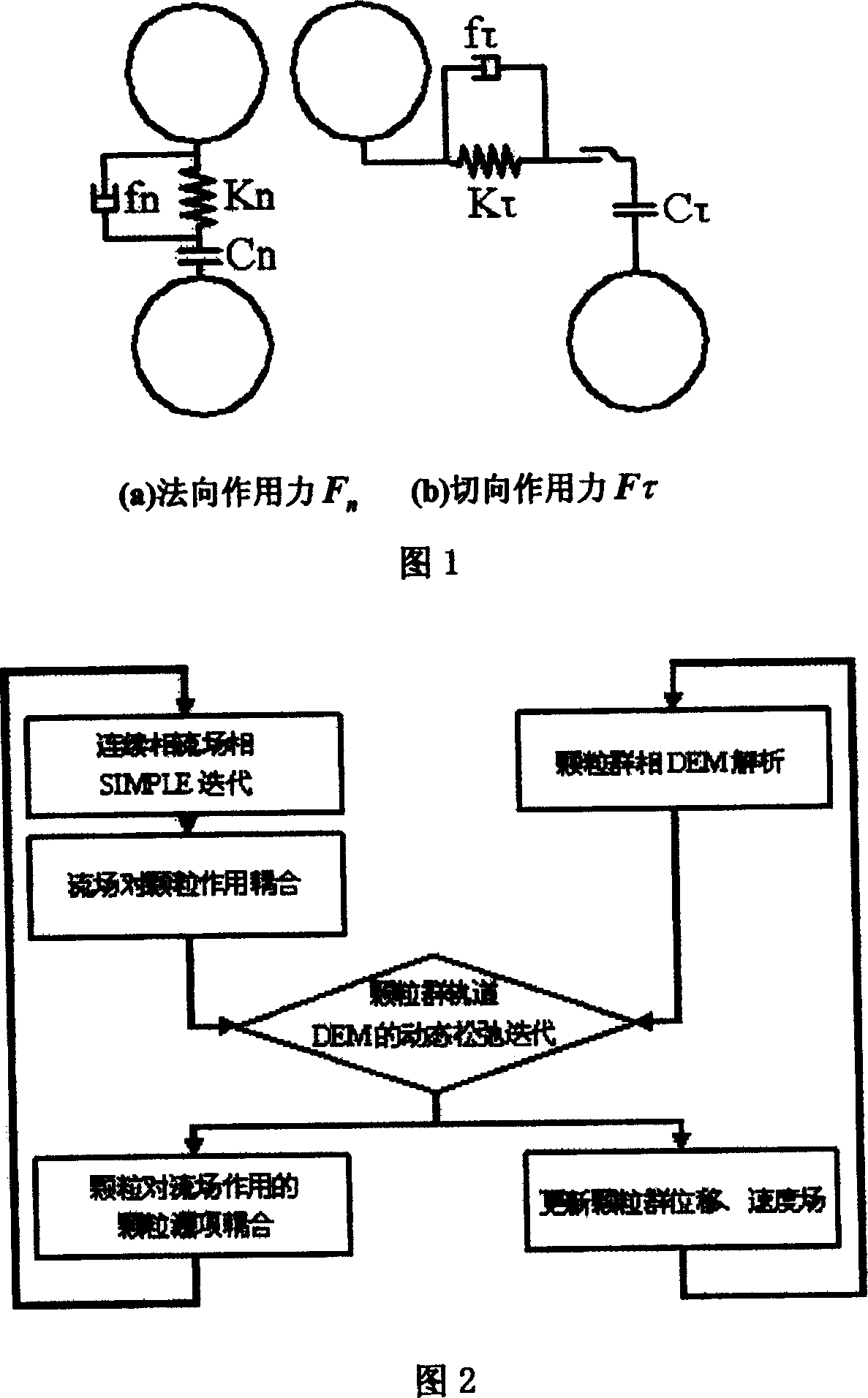

[0043] The basic principle of the three-dimensional discrete element method is to separate the discrete phase particles into a collection of discrete elements, use Newton's second law to establish the motion equation of each element, and solve the discrete phase particles by integrating the differential equation of the particle force in the Laplace coordinate system Trajectory, so as to obtain the overall motion behavior of the discrete phase particles. As shown in Figure 1(a) and (b), the three-dimensional discrete element method regards the collision between particles as inelastic collisions, and there is friction. This model simplifies the interaction of two spheres in spatial contact into springs, dampers and sliding friction devices. The contact force between particles includes elastic force, damping force and sliding friction force.

[0044] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com