Debugging device for integrated servo valve

A technology of servo valve and debugging board, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., to achieve the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

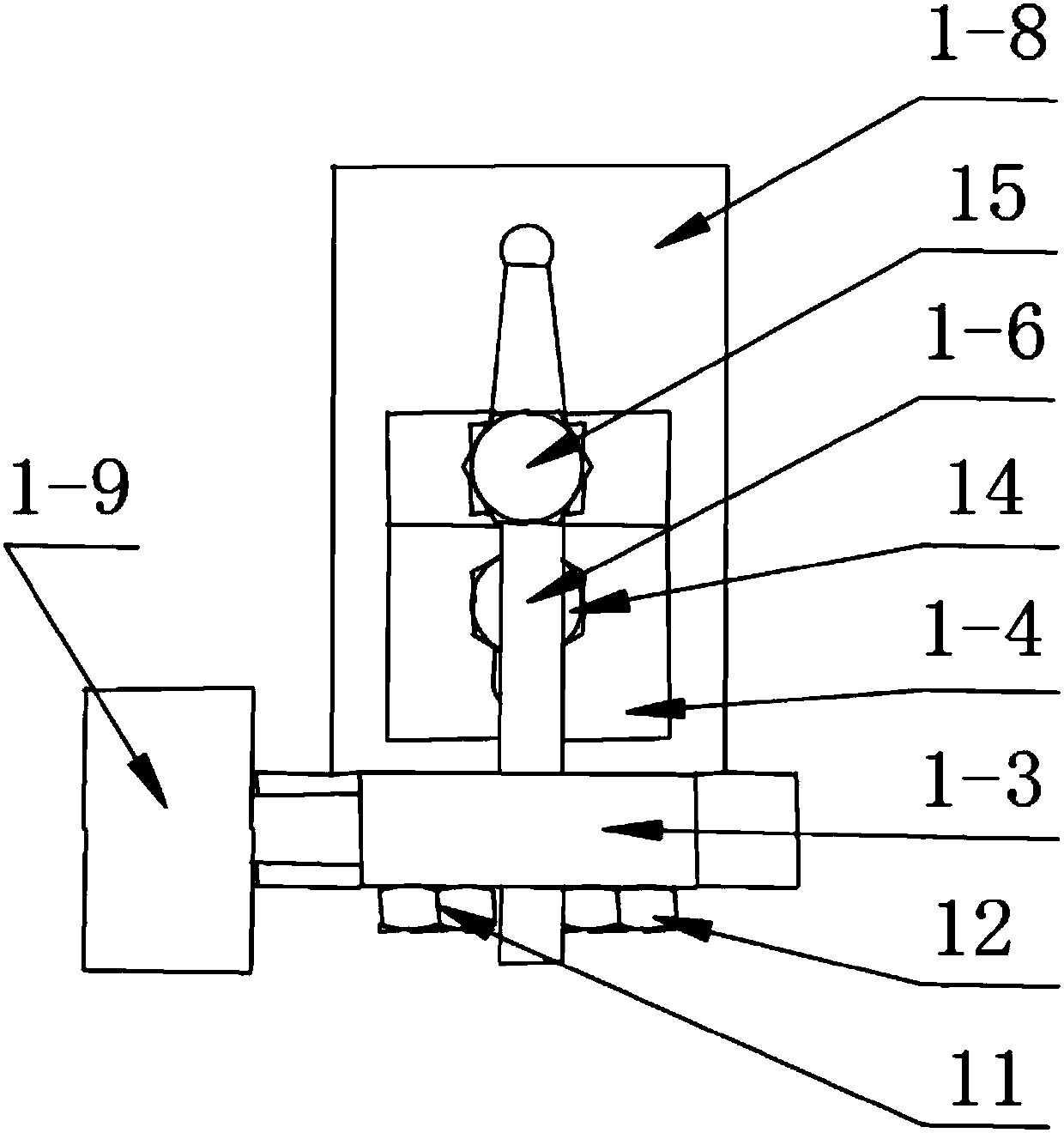

[0016] Such as figure 1 As shown, the integrated servo valve debugging device of the present invention is mainly composed of screw three 11, screw four 12, connecting plate 1-3, clamping block 1-4, screw five 14, loading rod 1-6, screw six 15, load Plate 1-8, limit screw rod 1-9 form. Screws three 11 and screws four 12 connect the connection plate 1-3 with the load plate 1-8, and by adjusting the screws three 11 and screws four 12, the connection plate 1-3 moves in the vertical direction. Screw six 15 connects the loading rod 1-6 with the clamping block 1-4, and drives the loading rod 1-6 to move by adjusting the front and rear positions of the clamping block 1-4. Screw five 14 connects the clamping block 1-4 with the load plate 1-8. Limit screw 1-9 can adjust and fix the position of loading rod 1-6.

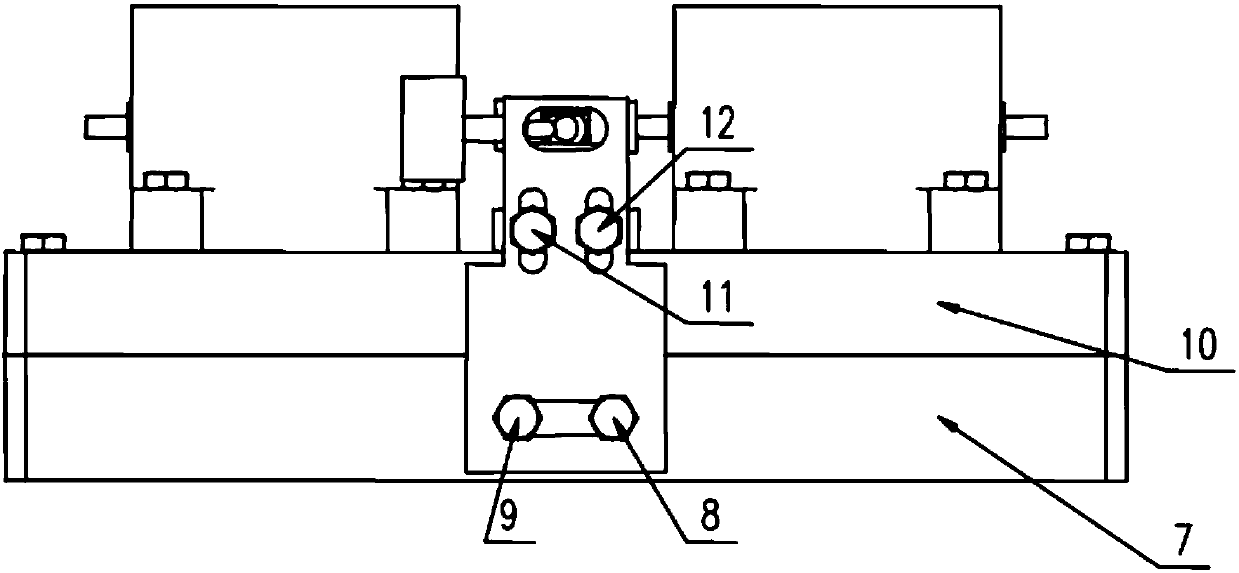

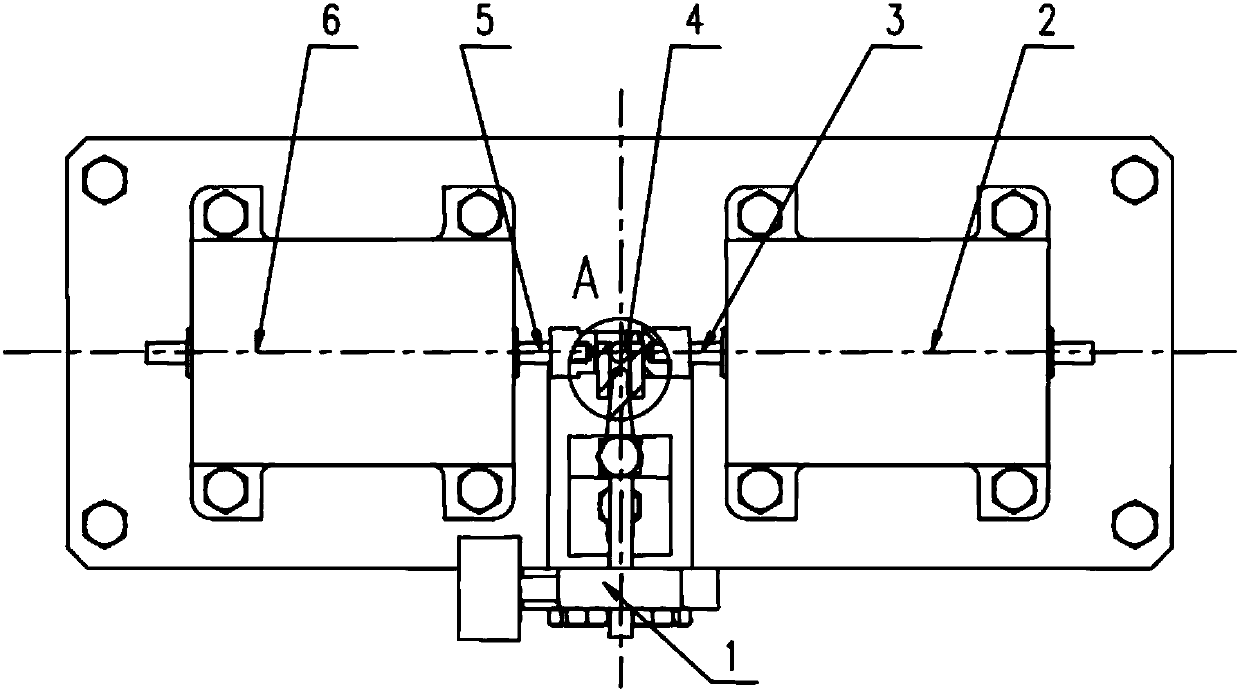

[0017] Such as Figure 2 to Figure 4 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com