Connecting device for connecting electric motor contact, motor fitted with same and motor engine fitted with same

A technology for connecting devices and contacts, applied in the components of connecting devices, electromechanical devices, conductive connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

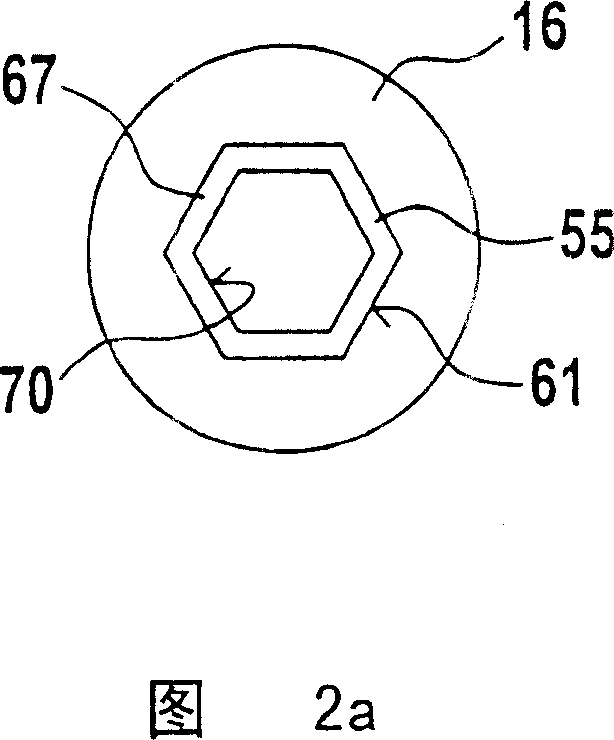

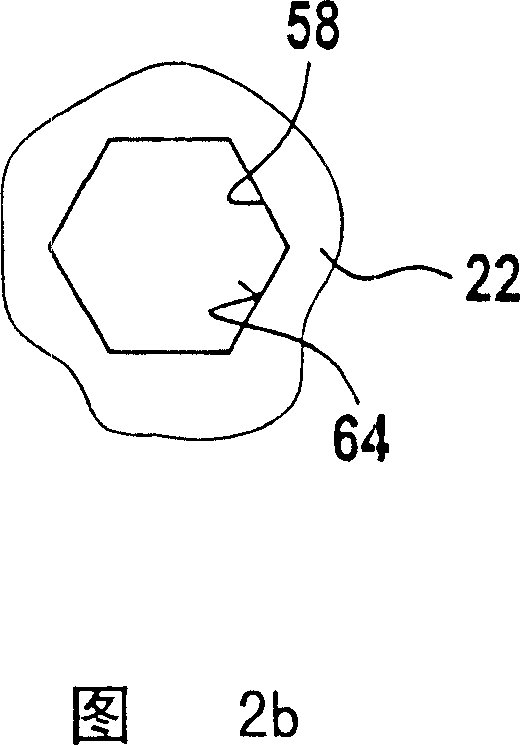

[0031] FIG. 1 shows a first exemplary embodiment of a connecting device 10 for contacting an electric motor 13 . The connecting device 10 has a first electrically insulating insulating part 16 (hereinafter referred to as the first insulating part) and a second electrically insulating insulating part 19 (hereinafter referred to as the second insulating part). A support 22 is accommodated between the two insulating parts 16 and 19 . A conductor part 25 connected thereto is connected to the second insulating part 19 . The first insulating part 16, the support 22, the second insulating part 19 and the conductor part 25 are non-detachably connected to each other. Insofar as it is not detachable, it means that at least one of these components must be destroyed to end the security of its connection. In this example, the aforementioned components are connected to each other by means of bolts 28 . In order to enable a good positioning of the connection device 10 on the support 22, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com