Steel-concrete combination backbone beam with big cantilever corrugated steel web overhanging beam

A corrugated steel web and concrete technology, used in bridges, bridge parts, bridge construction, etc., can solve the problems of lateral prestress loss of cantilever structures, large tear load of steel box girder webs, and reduced lateral prestress efficiency. Achieve the effect of improving the driving clearance conditions, the overall force performance and bearing capacity, and the structure and appearance are light and beautiful.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

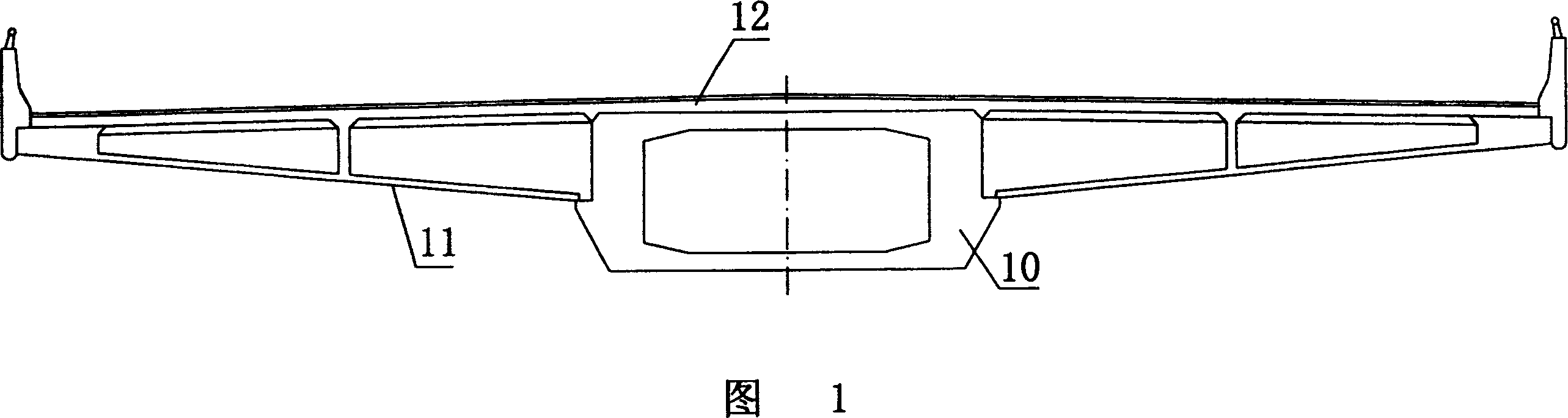

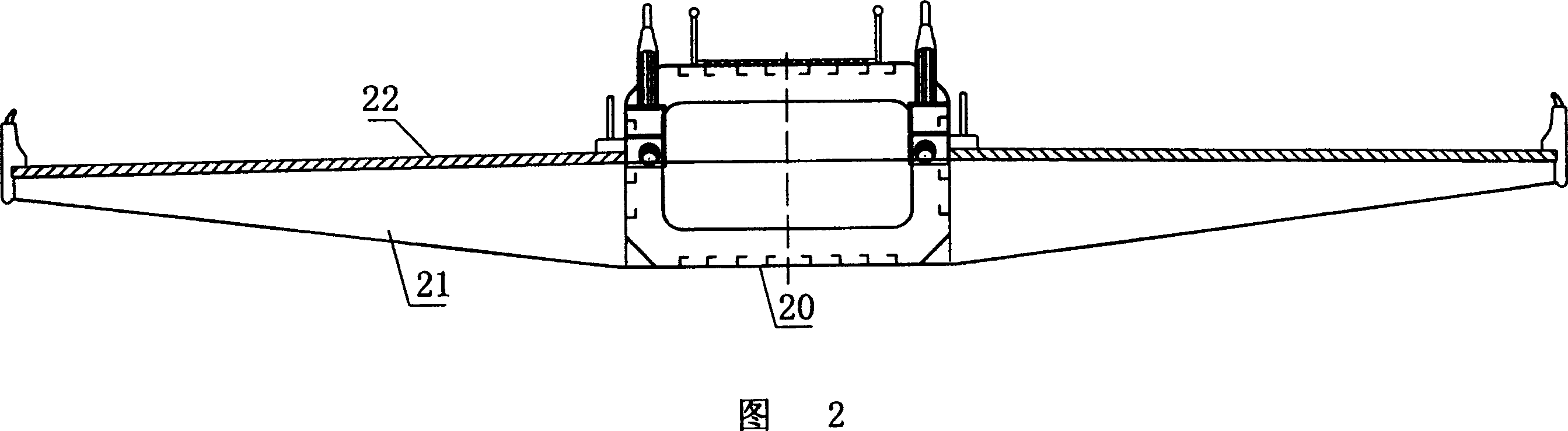

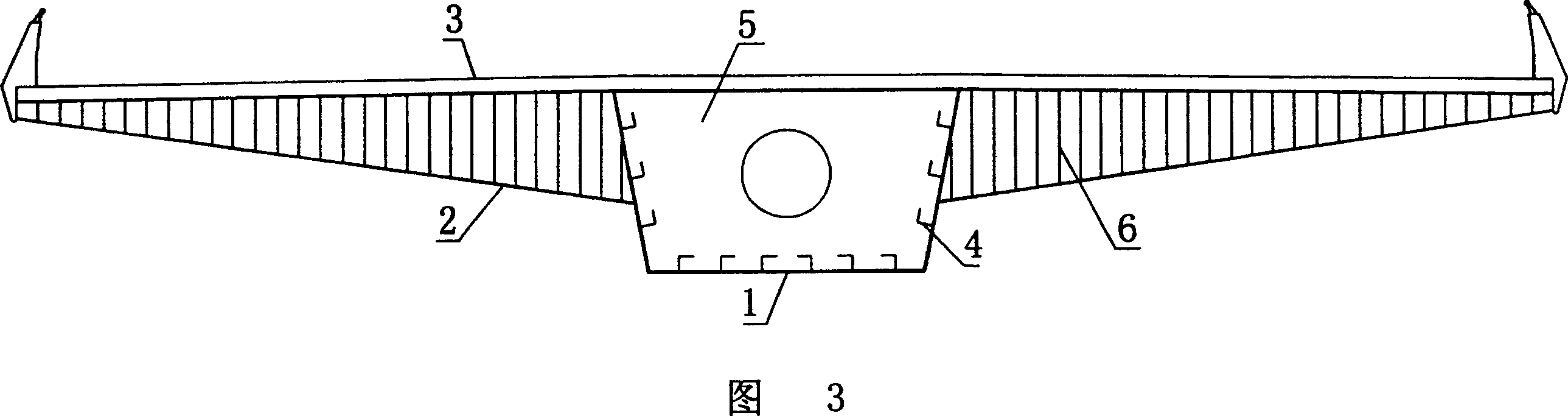

[0024] As shown in Fig. 3 and Fig. 4, the steel-concrete composite spine girder with large cantilever corrugated steel web cantilever of the present invention mainly comprises steel box girder 1, steel cantilever 2 and concrete bridge deck 3, steel box girder 1 Steel cantilever beams 2 are arranged symmetrically along the longitudinal direction on both sides of the web, and the top plate of steel cantilever girder 2 is flush with the top plate of steel box girder 1, which increases the clearance condition for driving under the bridge; The surface is no longer higher than the traffic lane on the top of the steel cantilever beam 2, which increases the traffic width of the bridge deck, so that the steel-concrete composite backbone beam can be well used in urban viaducts and overpasses, especially inclined bridges and bridges. Curved bridges, and can be well adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com