Electrochemical cell safety vent

An exhaust device, electrochemical technology, used in electrochemical generators, aqueous electrolyte batteries, batteries, etc., can solve the problems of small size and reducing battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

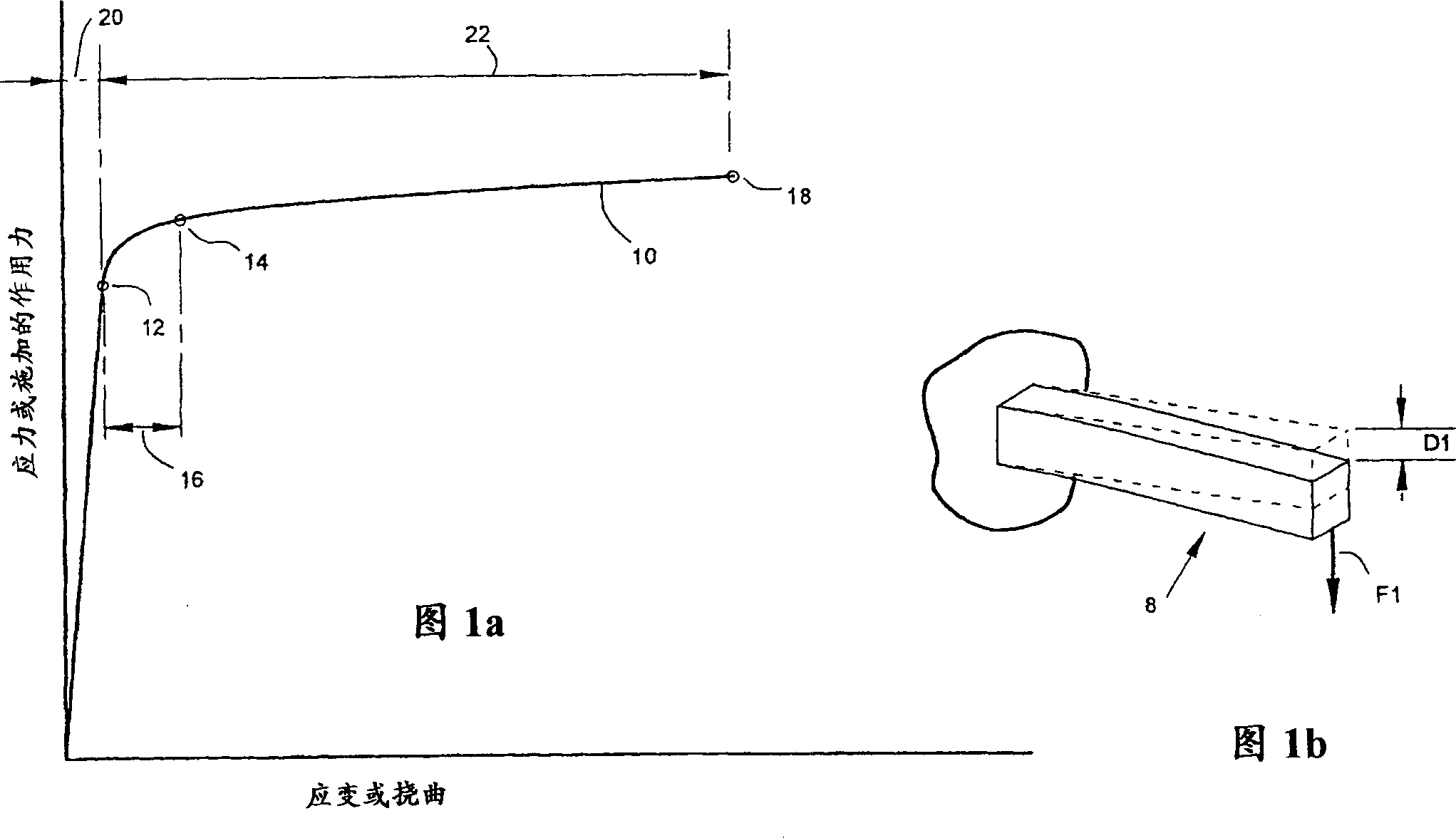

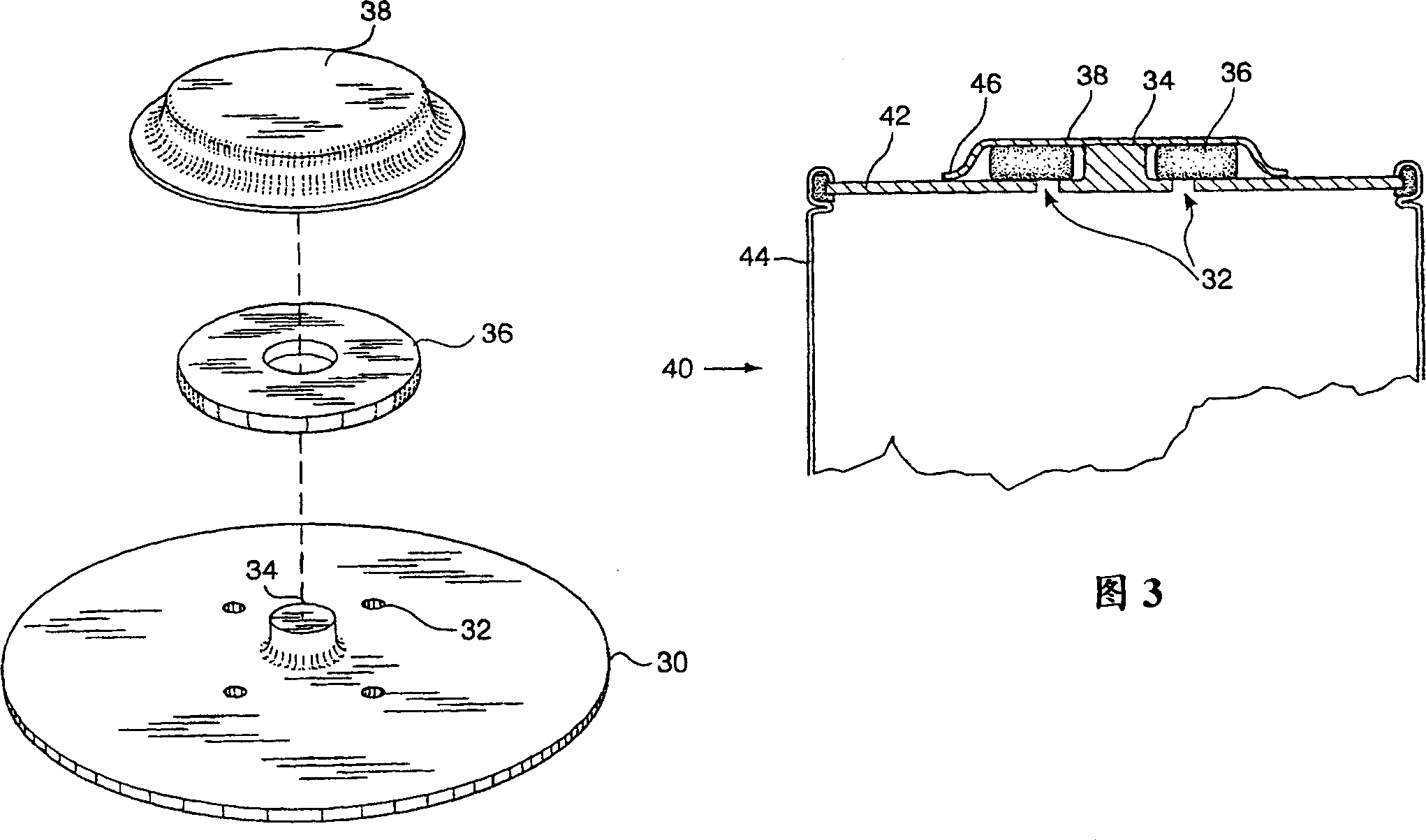

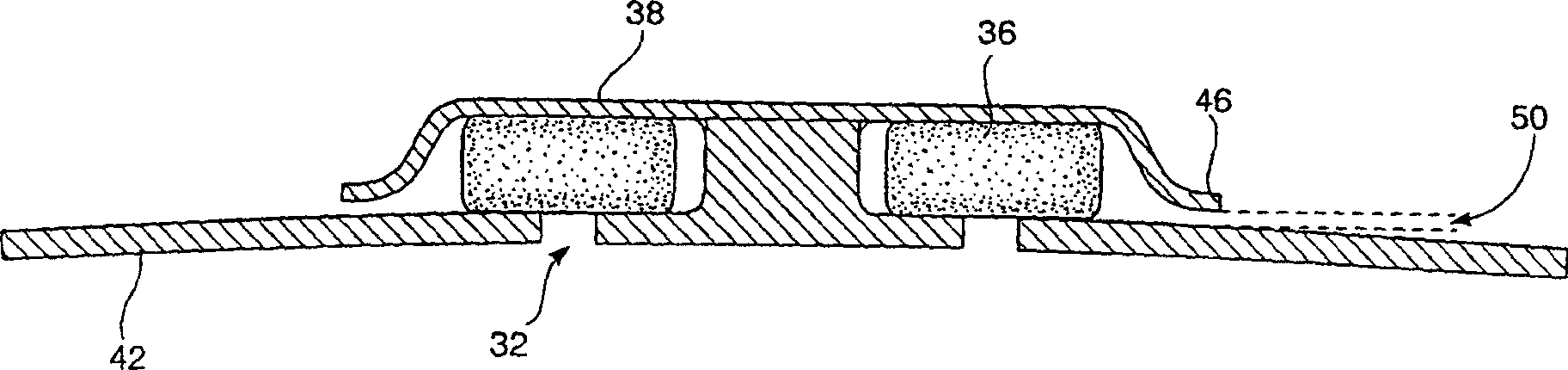

[0020] Sealed secondary batteries must be ventable to relieve internal pressure developed during transient conditions other than normal operating conditions. If the gas pressure exceeds the set discharge pressure and can be released smoothly, the pressure will be limited. If the amount of gas generated exceeds the exhaust volume or the exhaust is blocked, the internal pressure may increase rapidly. When softening plastics and similar low-melting materials are used in batteries, the risk of vent clogging increases at high temperatures. In the presence of materials and conditions that could cause the vent to clog, a large and open vent area is beneficial to ensure that the vent will not become clogged under destructive pressures. In order to provide the larger venting area needed to vent hot liquefied solids from the secondary battery, the present invention takes advantage of the larger deflection that occurs during pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com