Measuring instrument for space curve type long distance fine pipe internal surface shape and its detecting method

A space curve and shape measurement technology, applied in the direction of measuring devices, instruments, fluid tightness testing, etc., can solve problems such as irreparable, complicated rotating mechanism, and difficult access of CCD camera to the inside, so as to eliminate eccentricity error and reduce effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

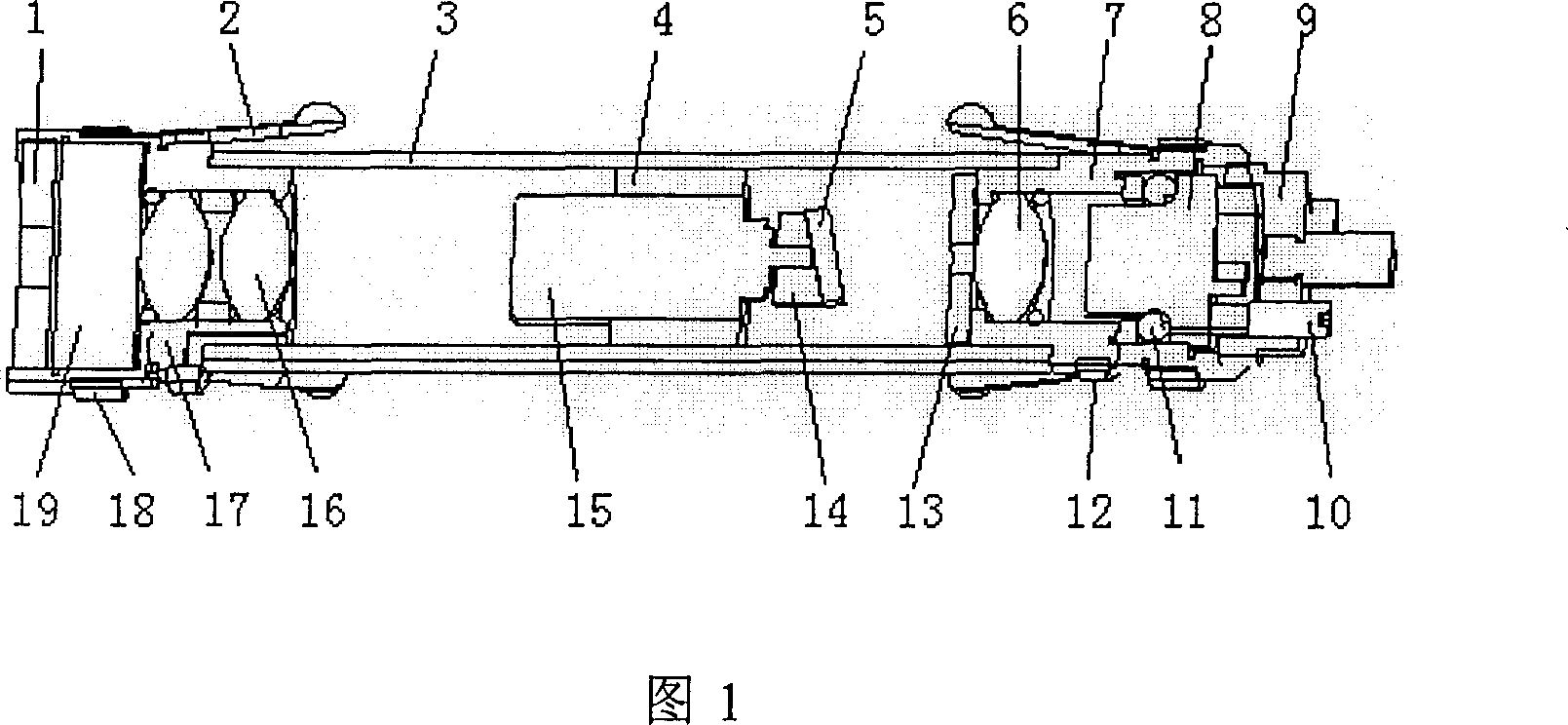

[0033] As shown in Figure 1, the space curve type long-distance micro-pipe inner surface topography measuring instrument has a two-dimensional position sensor base 17, a transparent window 3, and a laser base 7 connected in sequence, and a motor is fixed in the transparent window 3. Ring 4, on the motor fixing ring 4, a micro motor 15, a scanning mirror seat 14, and a scanning mirror 5 connected in sequence are fixed, and a two-dimensional position sensor pressure ring 1 and a two-dimensional position sensor are sequentially installed on the two-dimensional position sensor base 17. Sensor 19, receiving lens group 16, fixed antenna fixed ring 18, antenna adjusting screw piece 12 is fixed with elastic tentacles 2 on the antenna fixed ring 18 on the outer side of two-dimensional position sensor base 17, and is installed successively on laser base 7 Laser adjustment screw 10, laser pressure ring 9, semiconductor laser 8, elastic washer 11, converging lens 6, reflector 13, antennae ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com