High strength antiwear drilling bit of multiple rollers

A technology of roller cone bits and roller cones, which is applied in the direction of drill bits, drilling equipment, earthwork drilling and mining, etc., and can solve the problems of cone tip damage, roller cone alveolar wear, and reduction of the effective service life of roller cone bits. Achieve the effects of avoiding wear and tear, enhancing strength and wear resistance, and eliminating weak links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

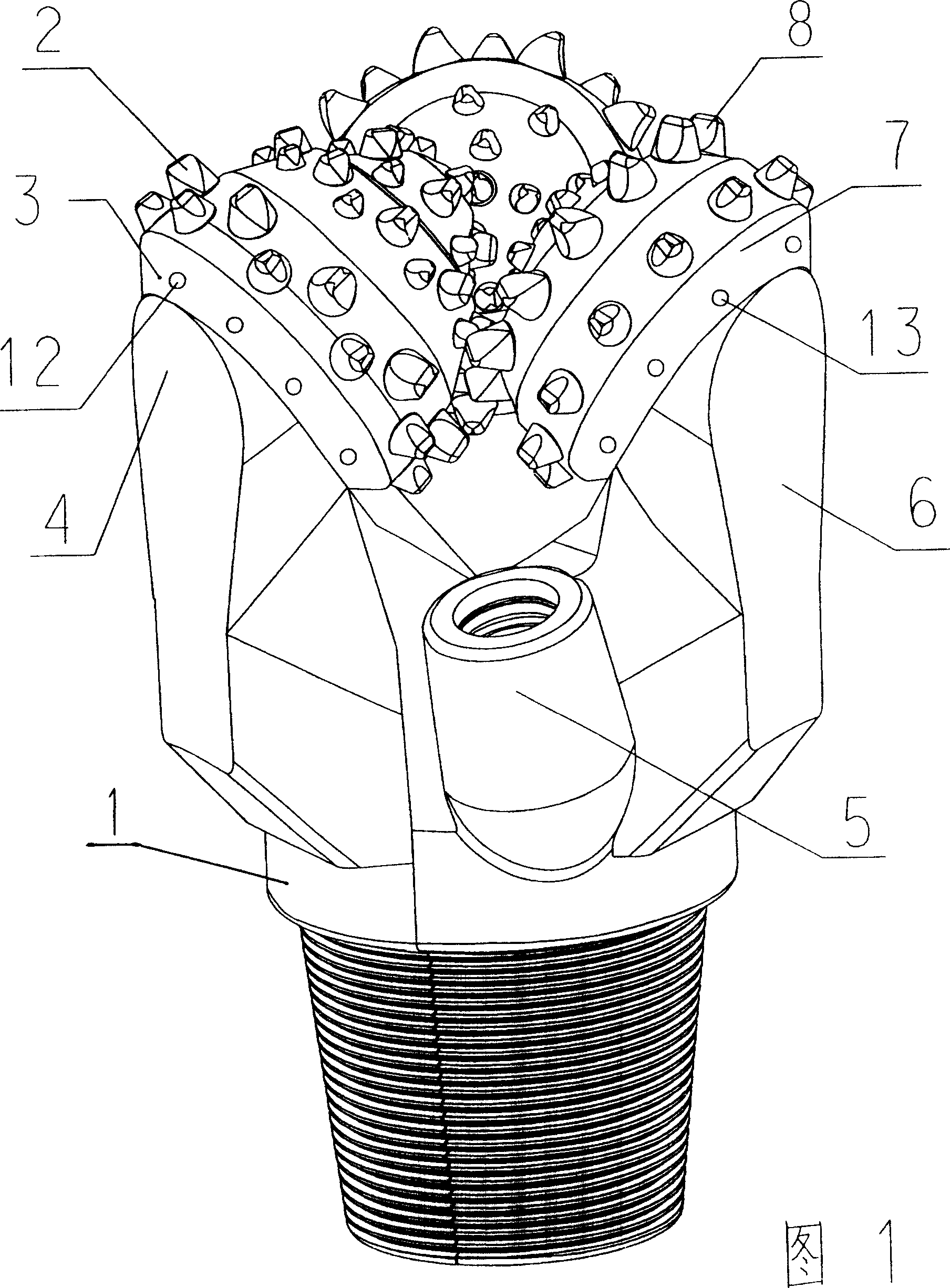

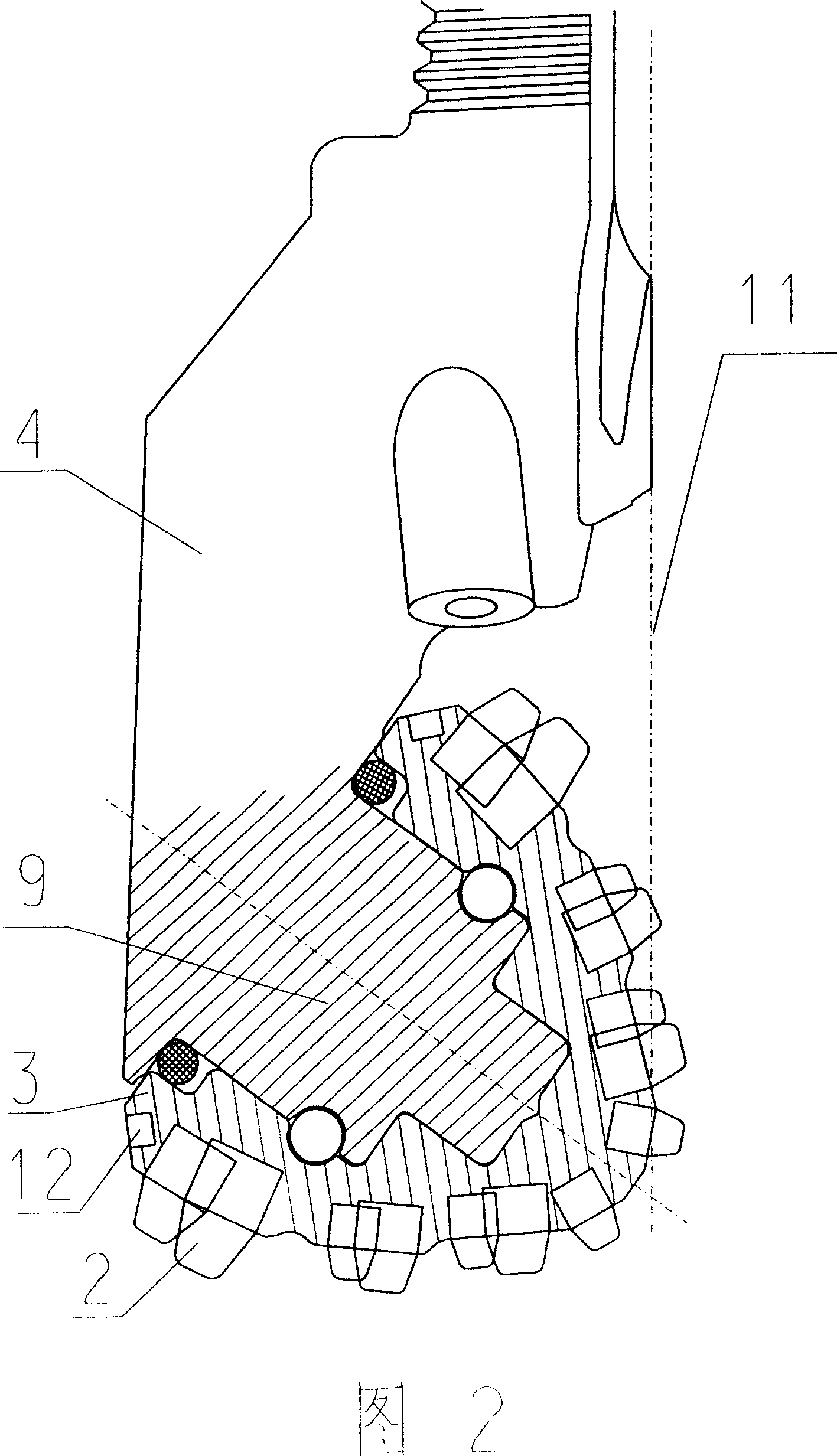

[0015] The first embodiment, as shown in Fig. 1, 2, 3, 4, 5, is an insert tricone bit, including three palms, wherein one palm 4 has a cantilever shaft 9 with larger diameter and length, and the other The two palms 6 are cantilever shafts 10 with smaller diameters and lengths. The cantilever shafts are composed of a large shaft and a small shaft at the end. The length of the shaft and the small shaft is long, and the ratio of the length is 1:0.6 to 0.8. The diameter of the large shaft and the small shaft of the cantilever shaft 9 is also larger than the diameter of the large shaft and the small shaft of the cantilever shaft 10, and the ratio of the diameter is 1:0.8 ~0.95, the cantilever shaft 9 with larger diameter and length is configured with the cone 3 with enlarged tip, the tip of the enlarged cone (the small head part of the cone) has larger axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com