Differential line driver

A line driver and driver technology, applied in the direction of differential amplifiers, line transmission components, circuits, etc., can solve problems such as instability and low signal bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

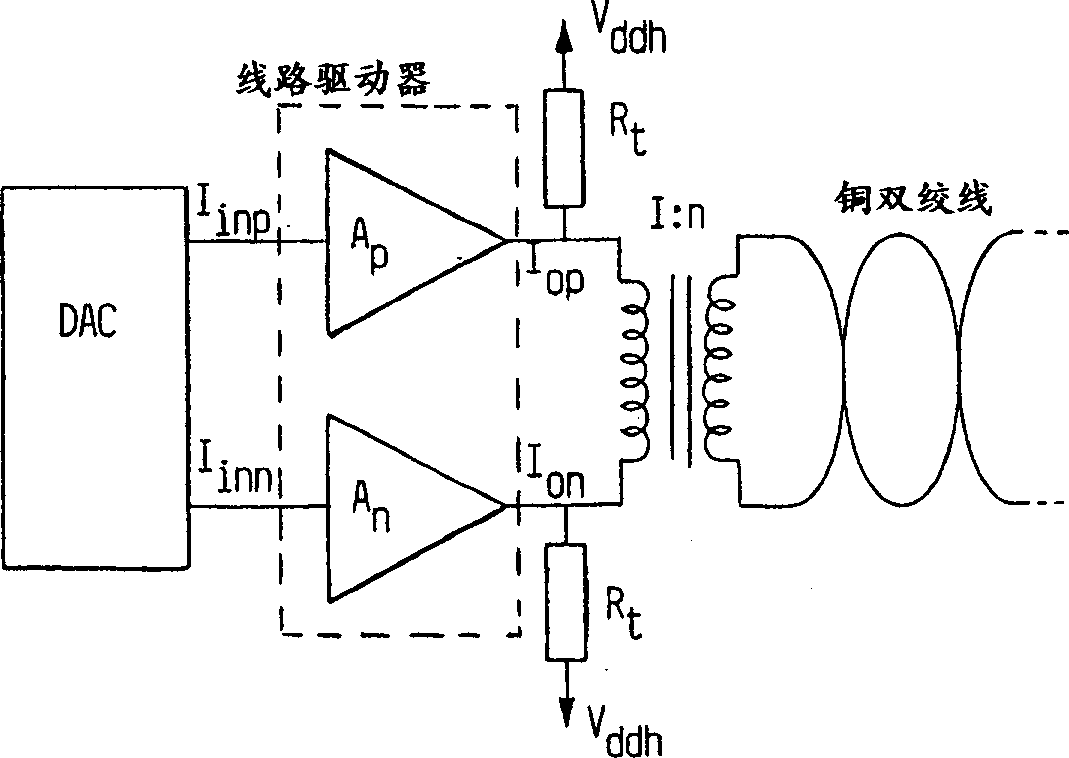

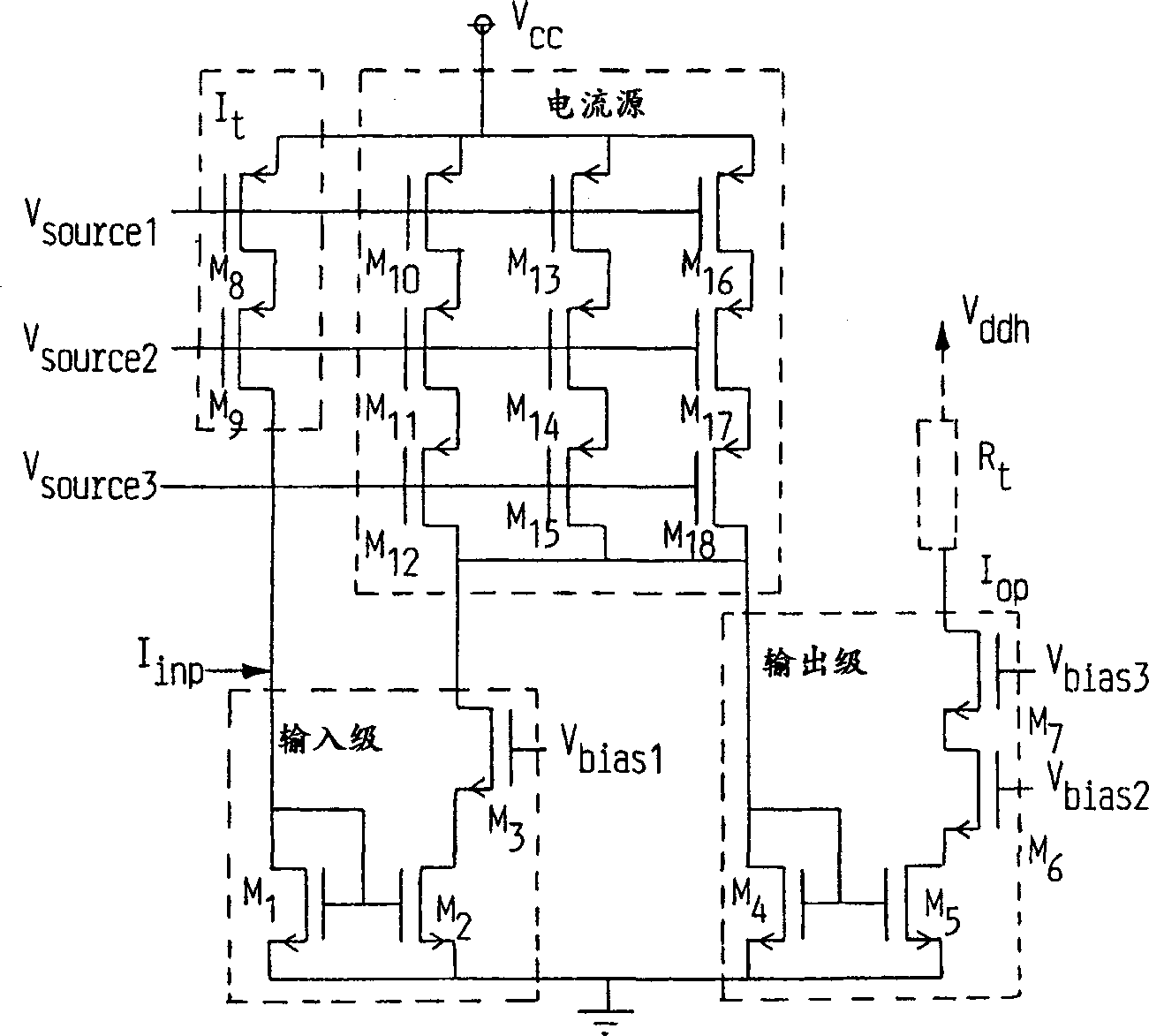

[0017] The general concept of the invention can be explained by figure 2 come to understand. A line driver is configured with a pair of current inputs I inp and I inn . The line driver (in the dotted rectangle) has a pair of current outputs configured with a ddh and connected to the terminal resistor R of the transformer coil t , while the other coil is connected to the copper twisted pair. Obviously, there is also a set of two current amplifiers A in the dotted rectangle p and A n .

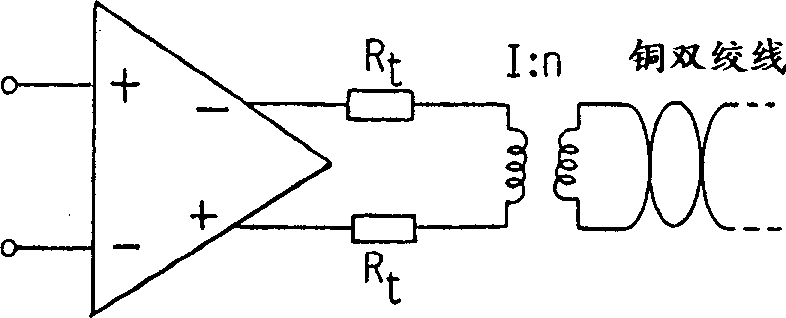

[0018] The line driver itself will have a very low input impedance in order to interface easily with a driving DAC. Different from the conventional scheme shown in Fig. 1, the line driver proposed by the present invention has a very high output impedance. With a low input impedance and a high output impedance, the line driver is a current-mode line driver. Port resistors at the output of the line driver will give a high common-mode rejection and impedance matching.

[0019] The effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com