Double-riser catalytic cracking device for lowering sulfur content in catalytically cracked gasoline

A catalytic cracking unit, catalytic cracked gasoline technology, applied in chemical instruments and methods, chemical/physical processes, multi-stage series-connected refining and cracking process treatment, etc., can solve the problem of high sulfur content in catalytic cracked gasoline, and achieve product distribution Good, gasoline octane improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

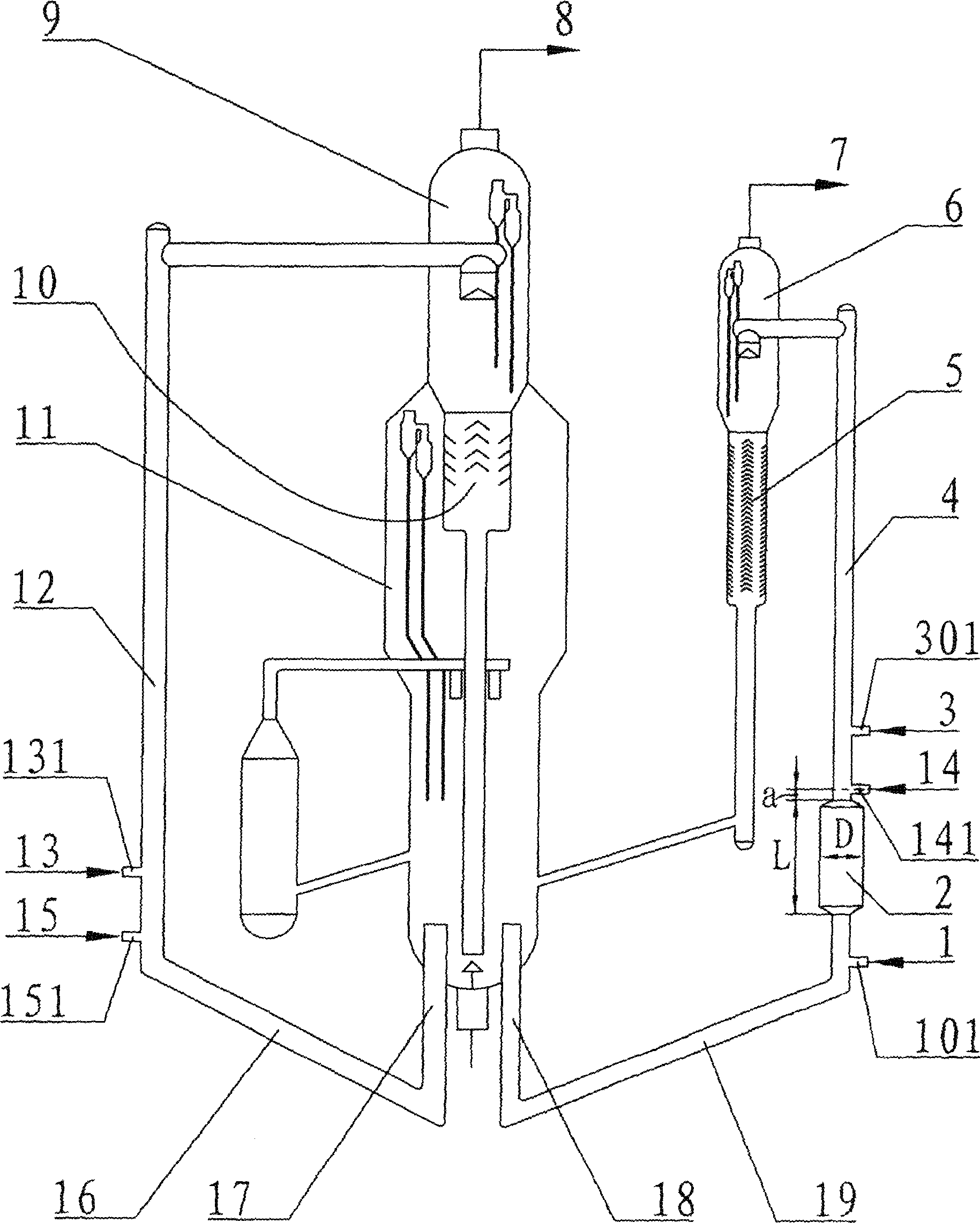

[0021] in such as figure 1 Experiments were carried out on the double riser catalytic cracking test device shown. The ratio of the inner diameter D of the bed reactor to the inner diameter of the gasoline riser reactor is 3.0, the length L of the bed reactor is 1 / 6 of the length of the gasoline riser reactor, and the top outlet of the bed reactor reaches the gasoline riser The vertical distance a of the center of the reactor lifting gas inlet is 1 / 10 of the length L of the bed reactor. The heavy oil riser reactor processing pipe transports mixed heavy oil (sulfur content is 0.78w%), and the processing capacity is 30kg / d (kg / day); the gasoline feed of the gasoline riser reactor is the gasoline produced by the heavy oil riser reactor (the sulfur content is 0.097w%), and the treatment capacity is 15kg / d. The pre-lifting medium of the bed reactor is catalytic cracking dry gas.

[0022] The catalyst used is the desulfurization catalytic cracking catalyst of the present invention...

Embodiment 2

[0028] According to Example 1, the difference is that the catalyst residence time in the bed reactor is 80s. The operating conditions and main properties of gasoline are listed in Table 1.

Embodiment 3

[0030] According to Example 1, the difference is that the catalyst residence time in the bed reactor is 100s. The operating conditions and main properties of gasoline are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com