Frame type combined dam

A frame type and embankment technology, which is applied in dikes, dams, coastline protection, etc., can solve the problems of slow construction speed, easy leakage, high labor intensity, etc., achieve advanced construction methods, eliminate internal and external stress, and occupy less land Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

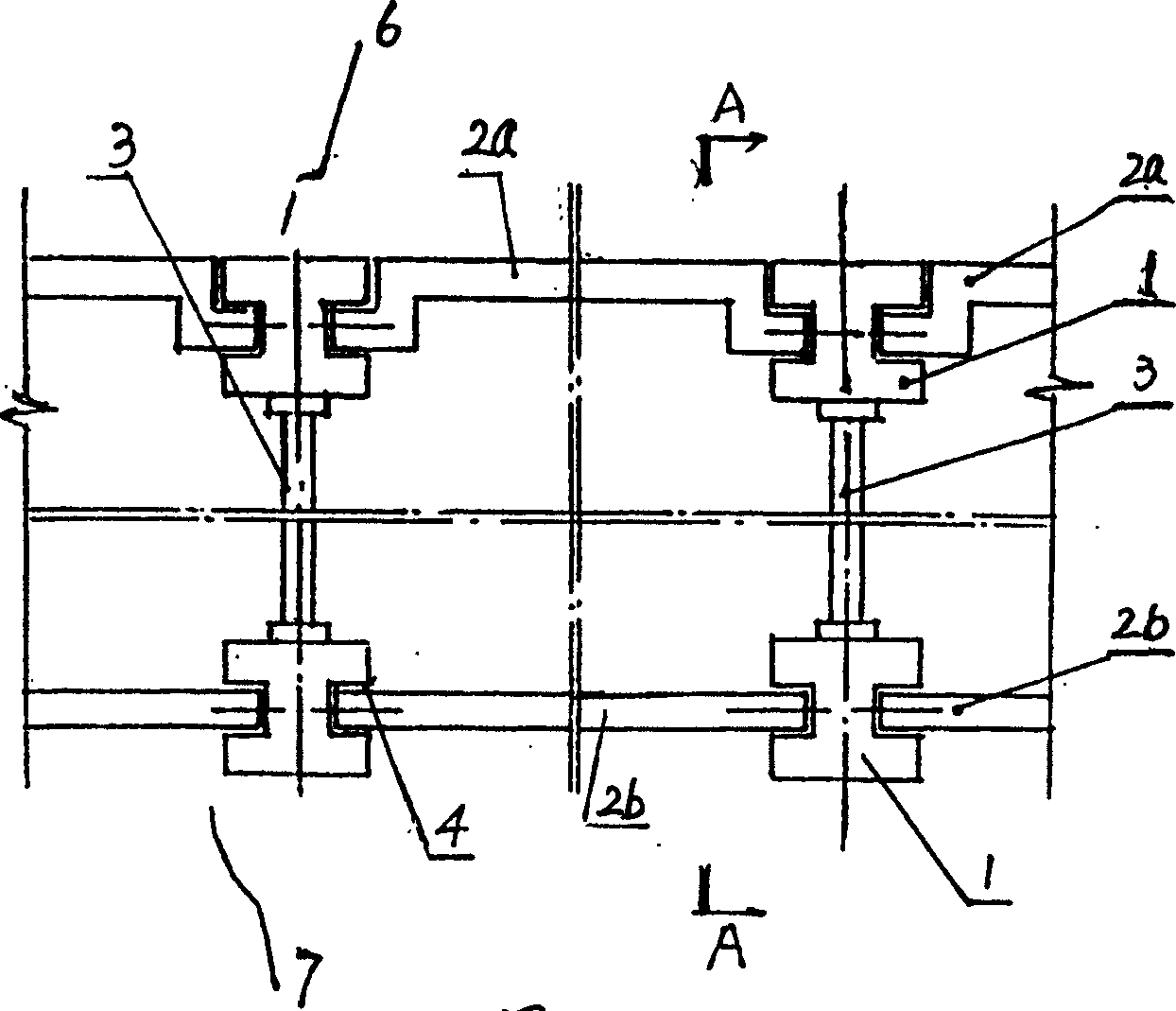

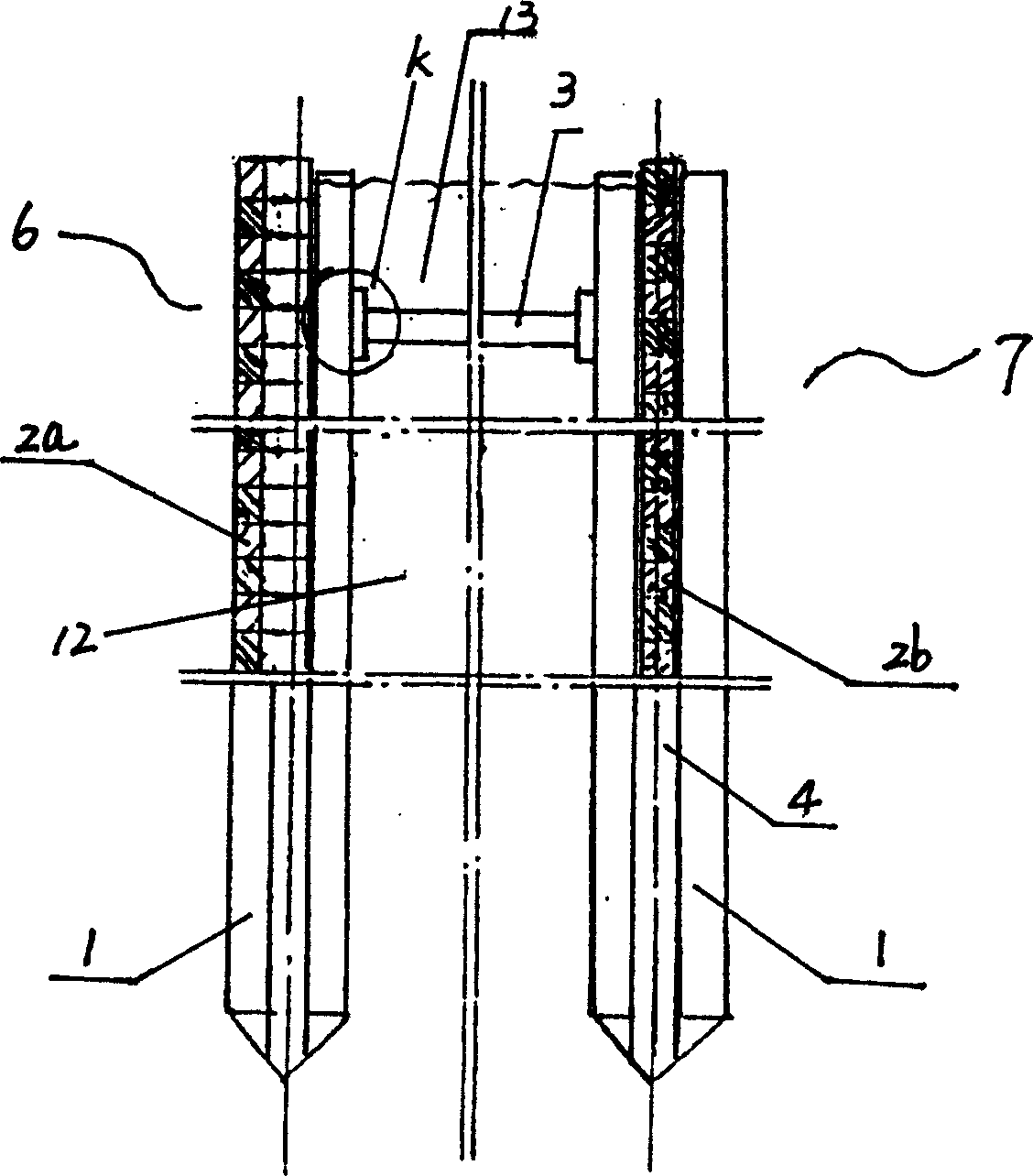

[0023] Embodiment 1. The frame type combined dam of the present embodiment is as figure 1 , figure 2 and Figure 9 As shown, it includes slotted piles 1, prefabricated panels 2a, 2b, and tie beams 3. The slotted piles 1 are arranged in two rows, and slotted piles 1 are provided with notches 4. The thickness is adapted to the size of the notch 4, and the prefabricated panels 2a and 2b are inserted into two adjacent grooved piles 1 in the same row in sequence, and the two ends of the tension beam 3 are respectively different from the adjacent two different piles. Groove pile connection. The bottom of the slot pile 1 is wedge-shaped. The bottom end of the bottommost block of the facing prefabricated panels 2a, 2b is wedge-shaped. During construction, the prefabricated grooved pile 1 is first deeply driven into the silt at the proposed embankment as the "pillar" of the frame, and then the left, right, front and rear sides of the exposed top of the positioned grooved pile 1 ar...

Embodiment 2

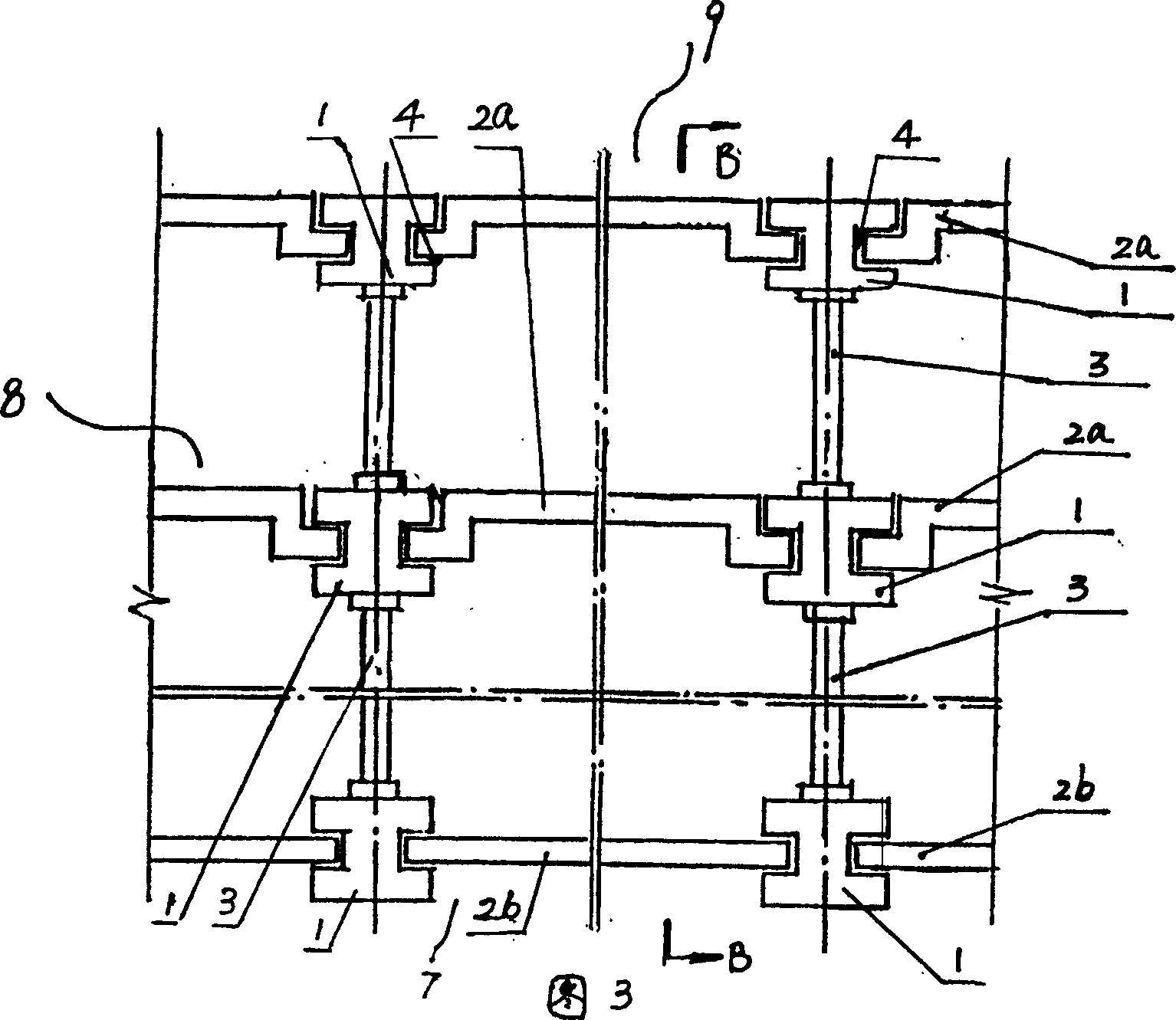

[0024] Embodiment 2. This embodiment can be seen from Fig. 3 and Fig. 4, and it differs from Embodiment 1 in that: the slot piles 1 are arranged in three rows. When the river bed is deep enough that the grooved piles 1 sink into the base sediment about 2m below the warning depth, at this time, another row of grooved piles must be built outside the 2 rows of armor, which becomes 3 rows of armor, and the tie beam 3 is used to position them outside. A deep-water stepped embankment in which the water (flood) level drops across the board is formed on the surface protection groove pile.

[0025] The thickness of the armor prefabricated plate of the frame type combined embankment of the present invention is preferably 10cm. The prefabricated panels on the surface of the river flow are made into a cross-section of a zigzag shape, such as figure 1 , figure 2 , Figure 3, Figure 4 shown. The cross-sectional shape of each block from the bottom to the top of the prefabricated slab exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com