Cooling system for turbine blade

A technology for turbine blades and blades, applied in the directions of blade support elements, stators, engine elements, etc., can solve problems such as expensive, complex casting processes, and high scrap rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

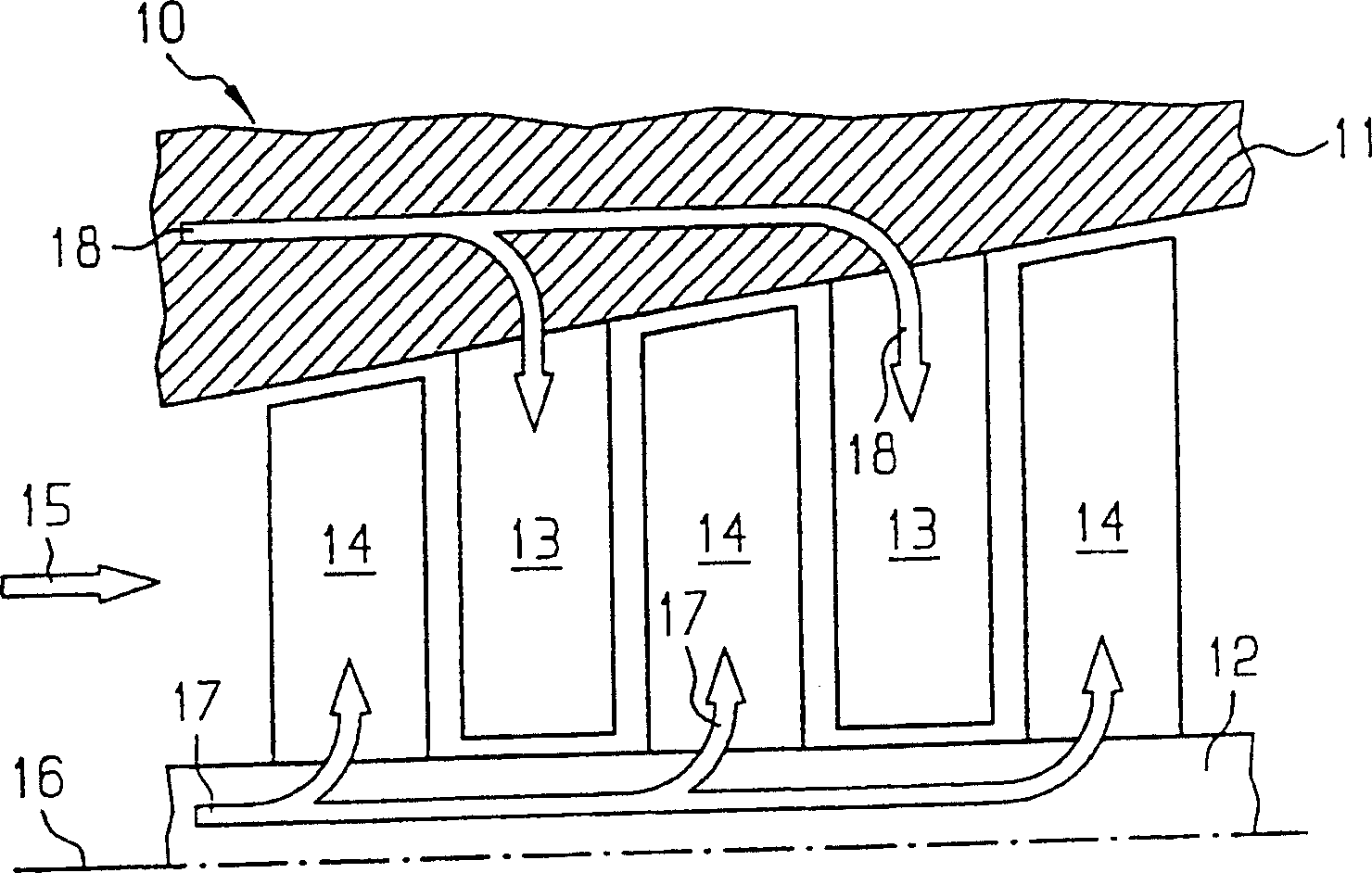

[0029] figure 1 A longitudinal sectional view of a turbine 10 with a housing 11 and a rotor 12 is shown. The housing 11 is provided with guide vanes 13 and the rotor 12 is provided with rotor blades 14 . In operation, fluid flows through the turbine 10 in the direction of arrow 15 , the fluid flows along the guide vanes 13 and rotor blades 14 , causing the rotor 12 to begin rotating about a centerline 16 .

[0030] In most applications, the temperature of the fluid is high, especially in the region of the first row of blades ( figure 1 shown in the center left). For this purpose, a cooling system is provided for the guide blades 13 and the rotor blades 14 . The flow of cooling fluid is schematically indicated by arrows 17 , 18 .

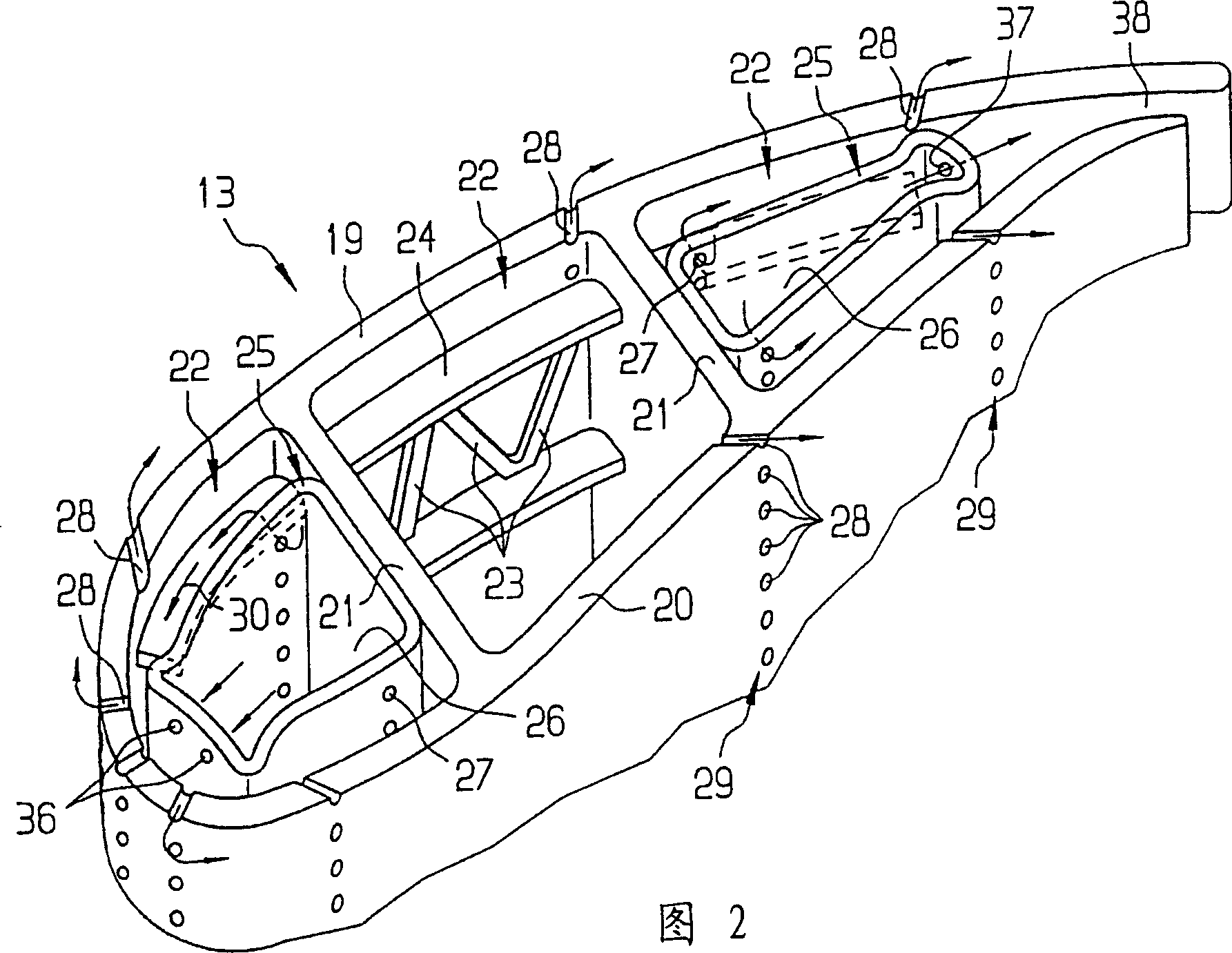

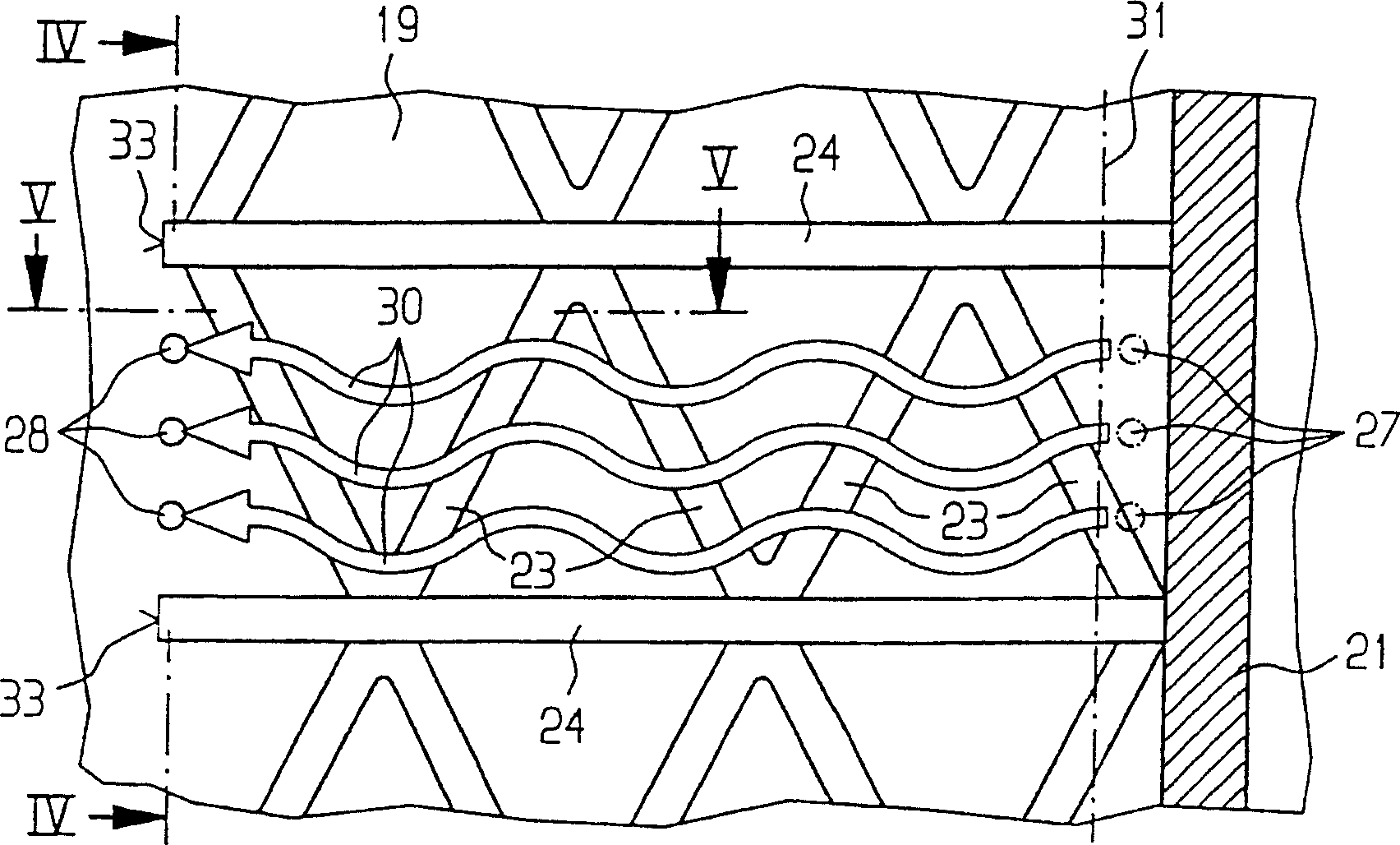

[0031] FIG. 2 schematically shows an exploded view of the guide vane 13 . The guide vanes 13 have curved outer walls 19 , 20 . The interior space between the outer walls 19 , 20 is subdivided into a total of three ducts 22 by means of two parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com