Method of raising wear resistance of base material

A wear-resistant and base material technology, which is applied in the field of increasing the wear resistance of the base material in the coating of wear-resistant coatings, and can solve the problems of ink smearing, poor adhesion, and easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

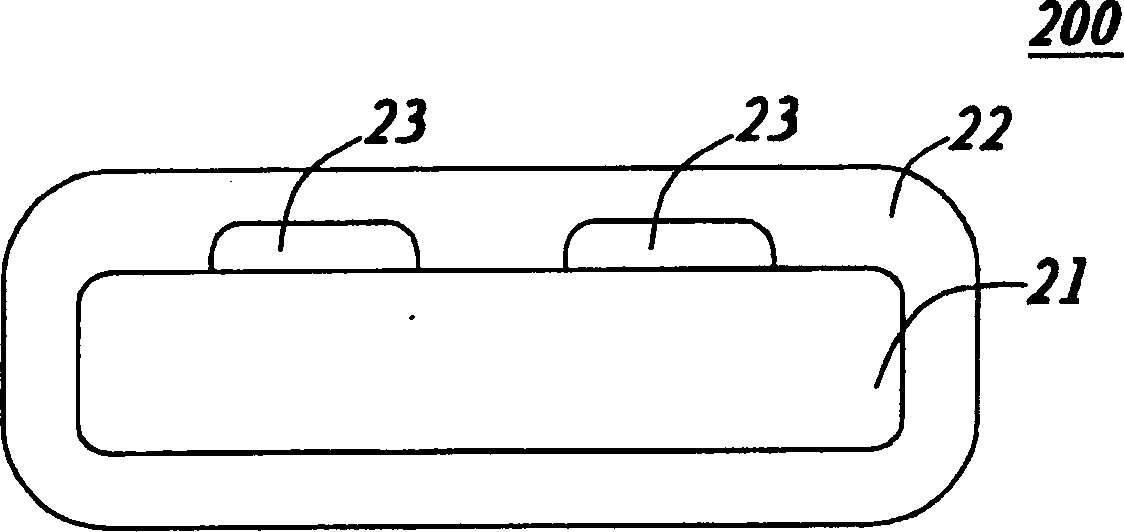

[0020] The invention provides a method for increasing the wear resistance of a substrate, which can be applied to any substrate that requires a printing process, which can be a plastic substrate or a PC substrate; the substrate itself can be a A transparent substrate or a non-transparent substrate. Please refer to figure 2 , the figure shows the window panel 200 completed according to the process method of the present invention. First, a base material 21 is injection molded. The shape of the base material 21 depends on the application of the window panel 200 , for example, a transparent base material applied to a window panel of a mobile phone. Next, surface printing is performed to form a printing layer 23 on the substrate 21. The printing layer 23 is determined according to the surface art design of the window panel 200, such as the manufacturer's brand name, text or pattern, and the like. Finally, a wear-resistant coating 22 is uniformly applied on the outside of the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com