Multicoloured label sheet forming method

A molding method and label sheet technology, which is applied in the field of label sheets, can solve the problems of labor consumption, lifelong vision damage, needle body and molding mold damage, etc., and achieve the effect of increasing production capacity and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

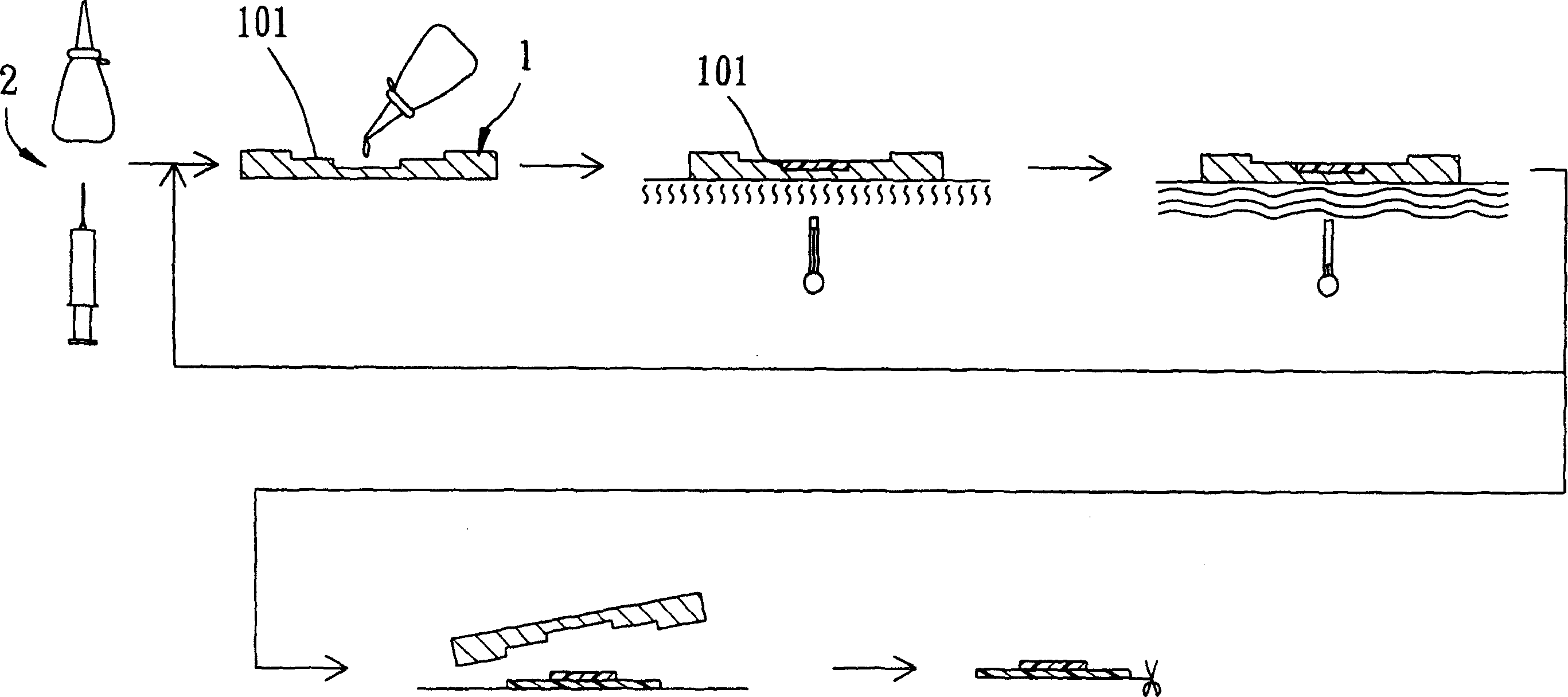

Method used

Image

Examples

Embodiment Construction

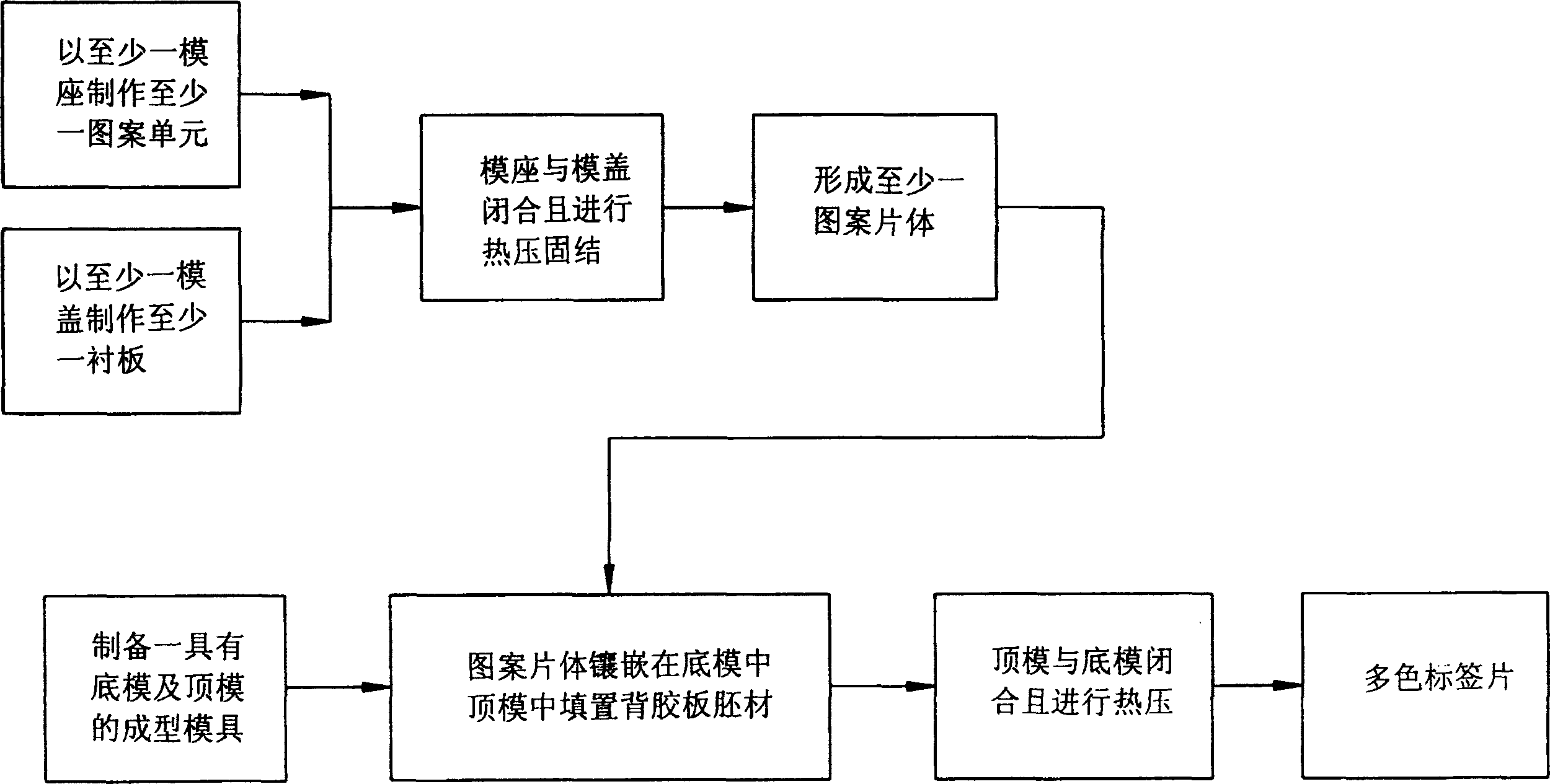

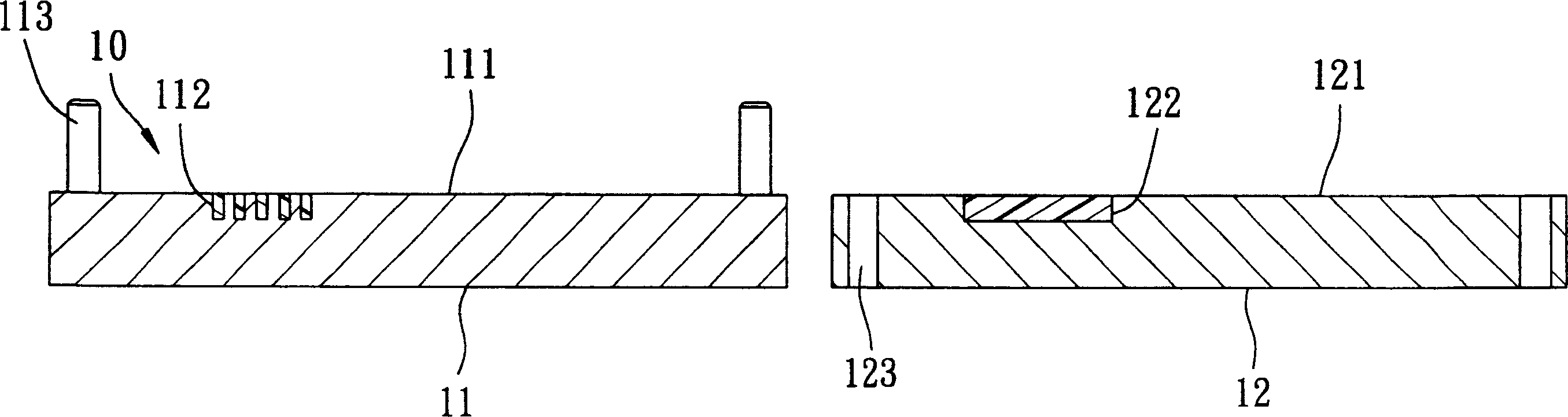

[0029] Refer to figure 2 , Picture 11 , The preferred embodiment of the method for forming the multi-color label sheet of the present invention is to use thermosetting plastic material as the base material to make a label sheet 100, the label sheet 100 has a backing sheet 110 and two different color combinations, different The pattern sheets 120 and 130 are patterned and fixed on the adhesive sheet 110. The backing board 110 has a side wall unit 110' that is circled along the contour, and each of the pattern sheets 120, 130 has a lining that is fixed to the backing board 110 and is different in color from the backing board 110. The boards 140 and 150 and a pattern unit 160 and 170 fixed on the backing boards 140 and 150 and having a different color from the backing boards 140 and 150. The pattern sheets 120 and 130 can be trademark graphics, characters, shapes, etc. that highlight the product. The present invention is more suitable for manufacturing the label sheet 100 with small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com