Hydraulic piston having enclosed cavity and method for making the same

A cavity and piston technology, applied in the field of hydraulic pistons and its manufacturing, can solve the problems of expensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

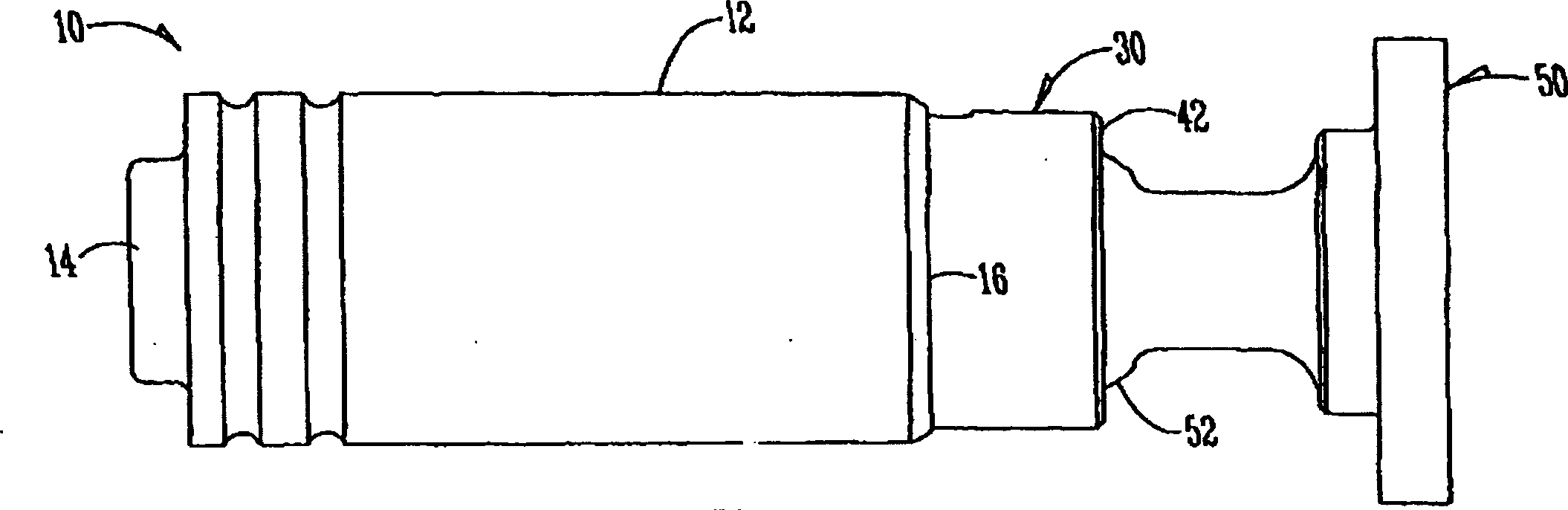

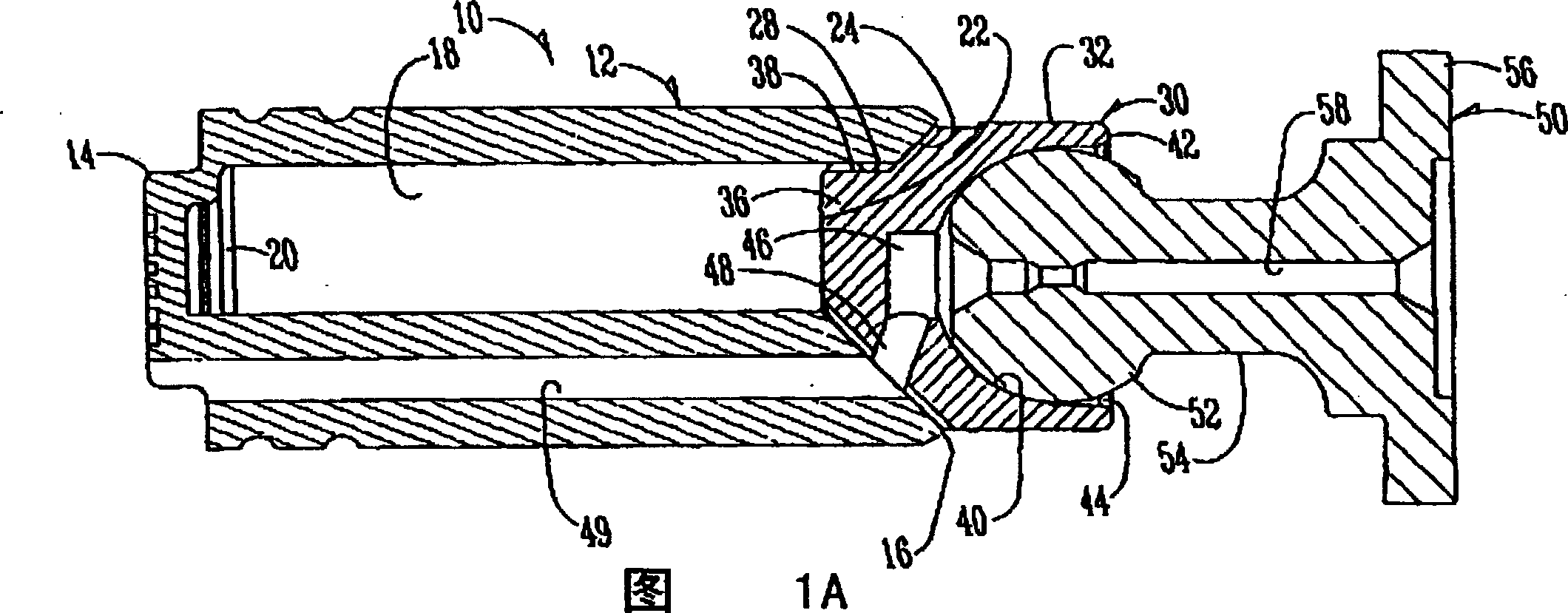

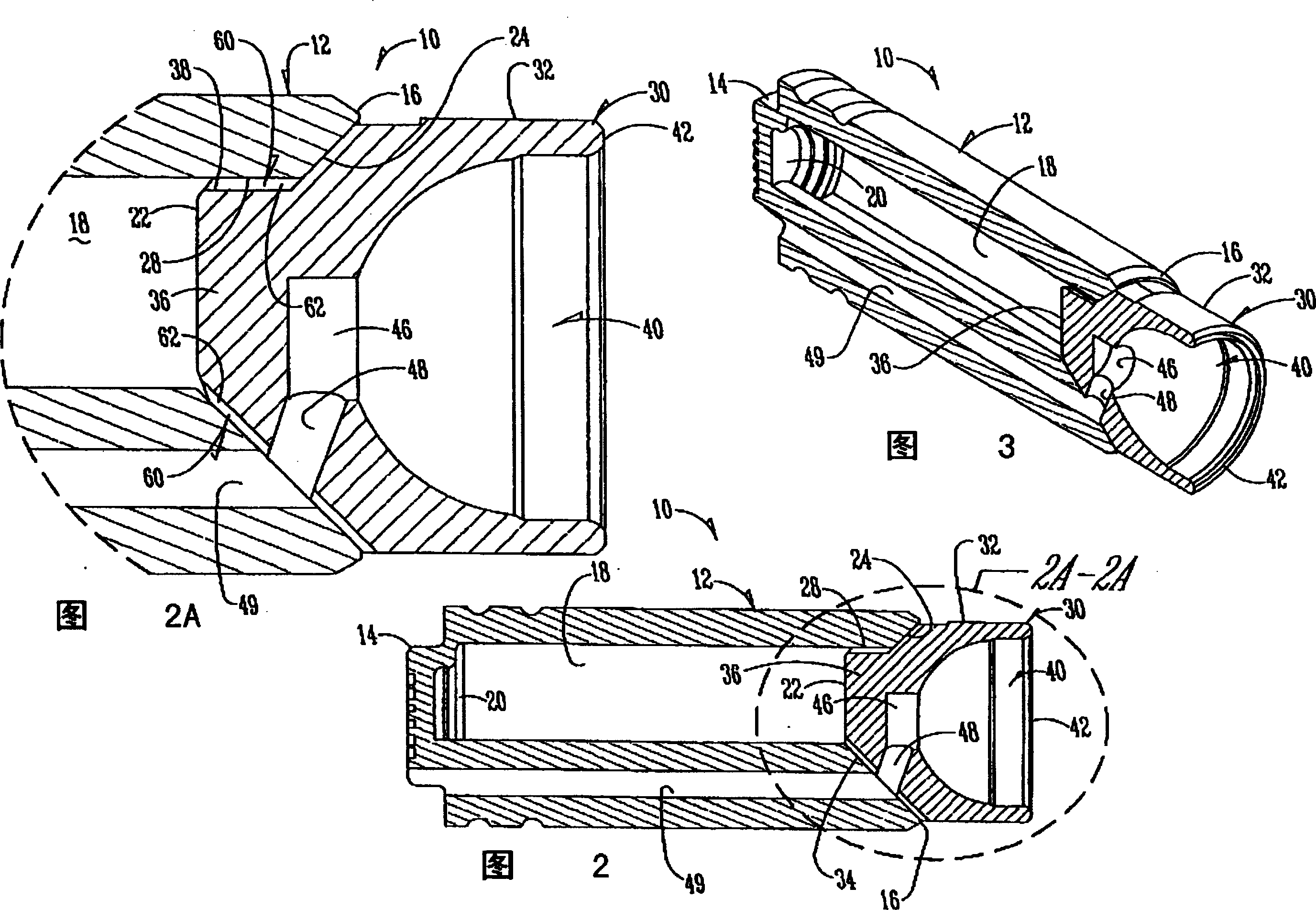

[0035] see figure 1 To 7, numeral 10 designates a hydraulic piston having a cylindrical body 12 with a first end 14 and a second end 16. An elongated cavity 18 is formed in the body 12 and has a first end 20 and a second end 22 . A tapered surface 24 is formed on body 12 at second end 22 surrounding cavity 18 . Referring to FIG. 2A , a cylindrical side wall portion 28 extends inwardly from the inner tapered surface 24 .

[0036] Cap 30 has a cylindrical head 32 and a tapered side wall 34 (FIG. 4). A cylindrical stub 36 extends inwardly into the cavity

[0037] 18 of the second end 22 . Post 36 has a cylindrical side wall 38 which extends into cavity 18 at its second end.

[0038] Cover 30 has a curved ball socket 40 which terminates in an annular lip 42, such as figure 1 As shown in A. A small space 44 will accommodate the curling of the lip 42 in an inward direction, as will be discussed below.

[0039] The cover 30 has a central conduit 46 aligned with an angled cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com