Intelligent multilayer barrel type net vibrating screen

A vibrating screen, intelligent technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of missing drilling conditions, affecting the processing capacity, inconvenient to equip cuttings post-processing device, etc., to improve the separation effect, The effect of increasing the throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further illustrate the present invention below in conjunction with accompanying drawing.

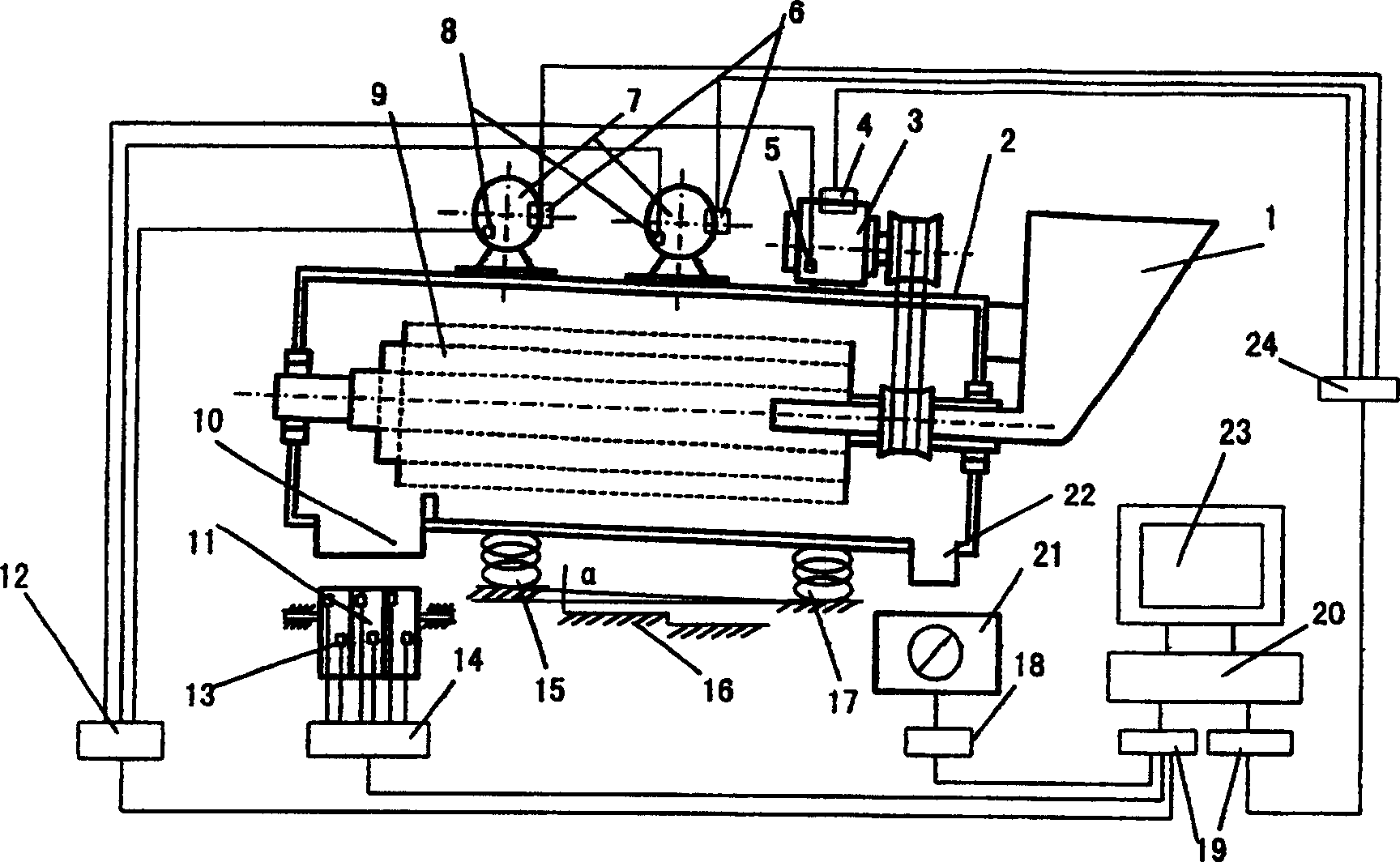

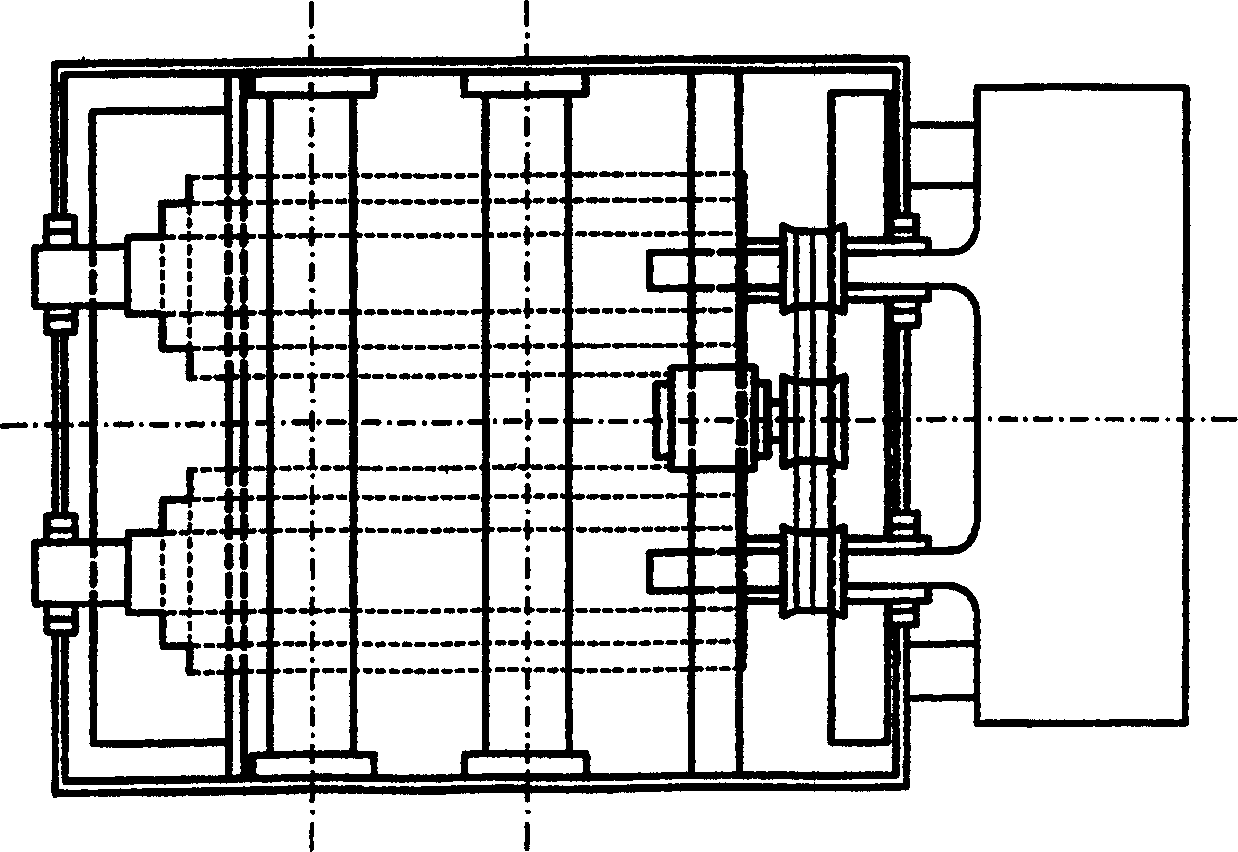

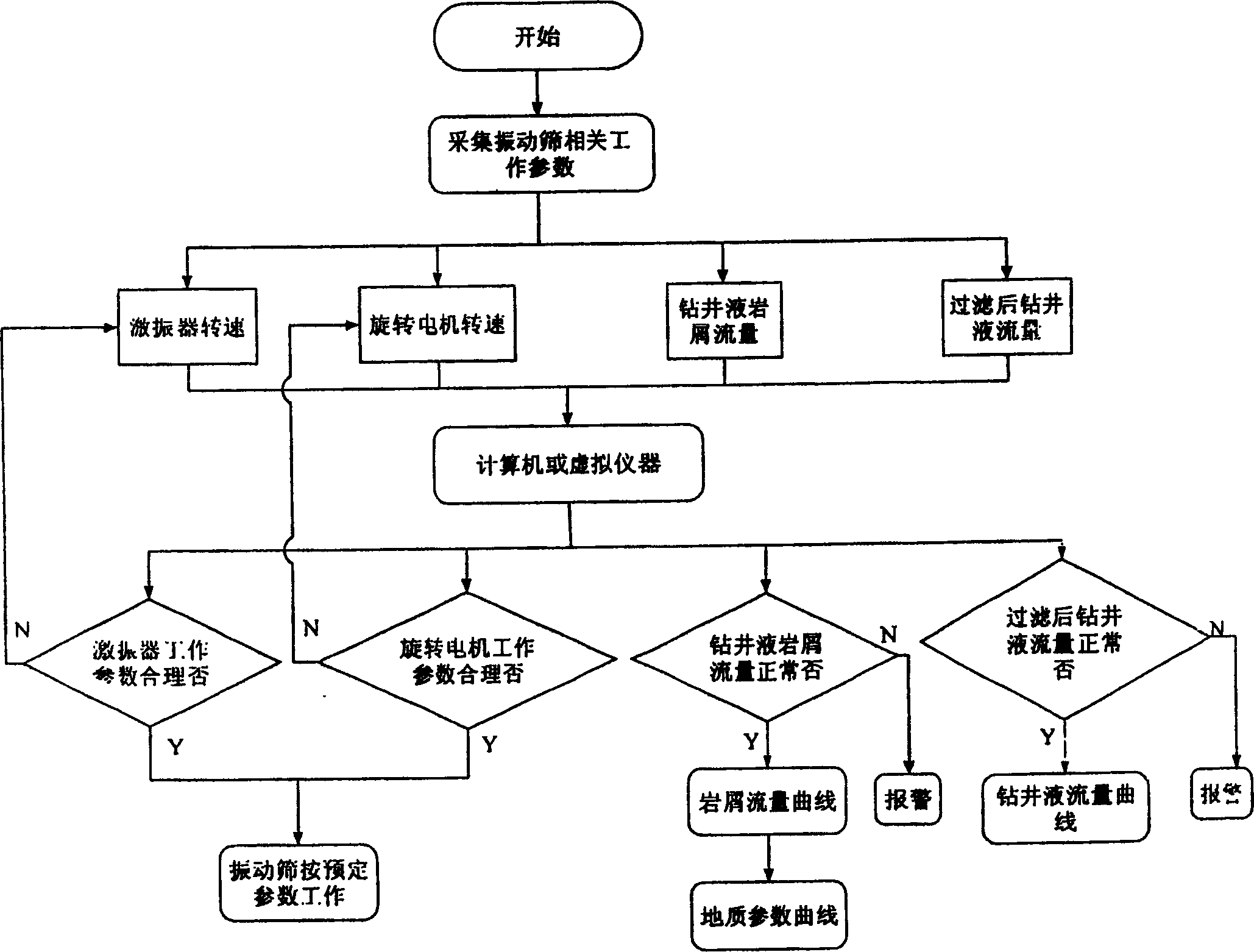

[0016] see figure 1 , figure 2 , an intelligent multi-layer cylindrical screen vibrating screen, characterized in that it consists of a screen box (2), a vibrator (7), a rotating motor (3), a multi-layer cylindrical screen (9), a drilling fluid cuttings flow Intelligent metering device (11), drilling fluid flowmeter (21), base (16), automatic control system, data processing and analysis system, etc., screen box (2) is supported on the base ( 16), the exciter (3) includes two or more explosion-proof motors or other types of excitation motors, and the automatic control system consists of a response sensor (5) (8) and a controller (6) (4) , the data analysis and processing system consists of counting sensor (13), secondary instrument (12) (14) (18) (24), A / D card (19), equipped with special analysis software computer or virtual instrument (20), It is composed of parts such as dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com