Equipment for continuous automatic measuring resistance of conducting material

A conductive material and automatic measurement technology, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, measuring devices, etc., can solve problems such as time-consuming, inaccurate measurement data, waste of manpower, etc., to ensure product quality and improve The effect of uniform distribution of cost ratio and resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

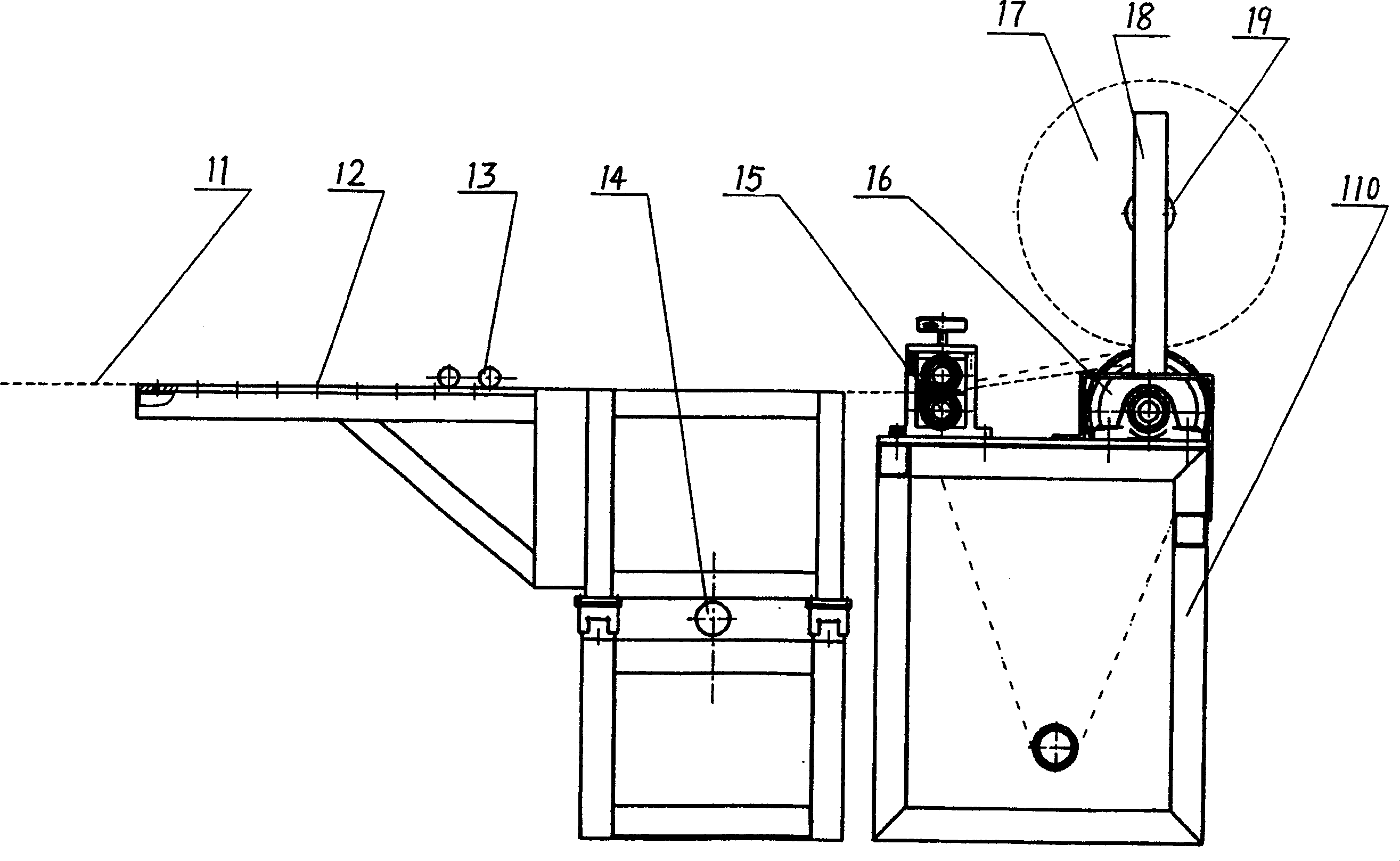

[0018] Such as figure 1 As shown, the equipment for continuously and automatically measuring the resistance of conductive materials is mainly composed of three parts: a deviation correction mechanism, a continuous resistance value detection system and a winding system.

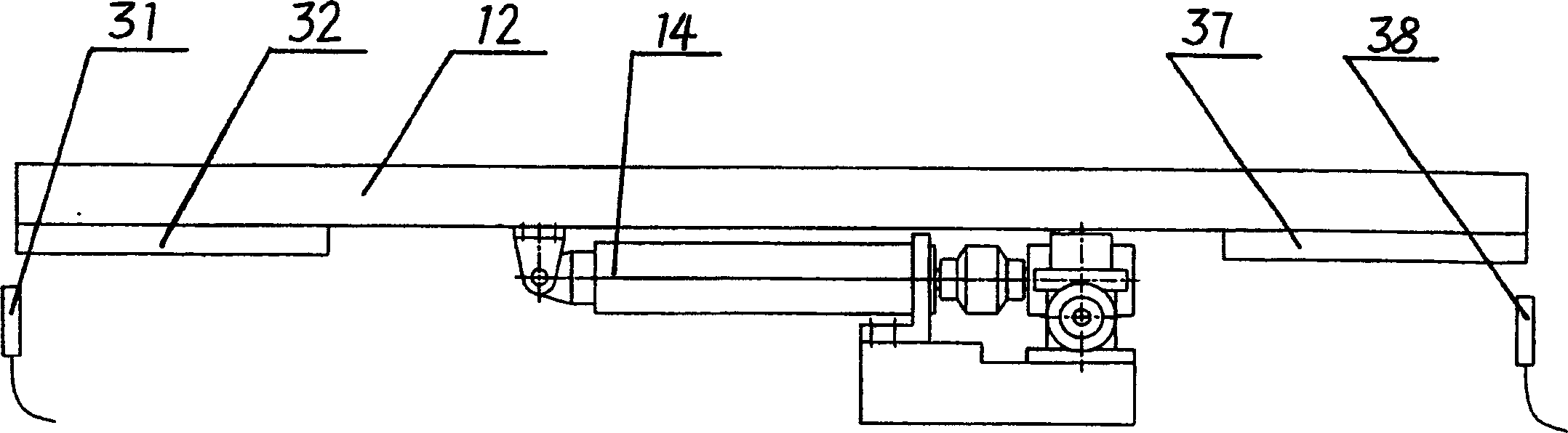

[0019] The support plate 12 is provided with a deviation correction pressure roller 13, and the support plate 12 is provided with a deviation correction mechanism 14, and is controlled by a central controller. The support plate 12 and the deviation correction mechanism 14 are all installed on the support frame. The detection system 15 and the winding system are installed on the winding frame 110, and the detection system 15 is located between the deviation correction mechanism 14 and the winding system.

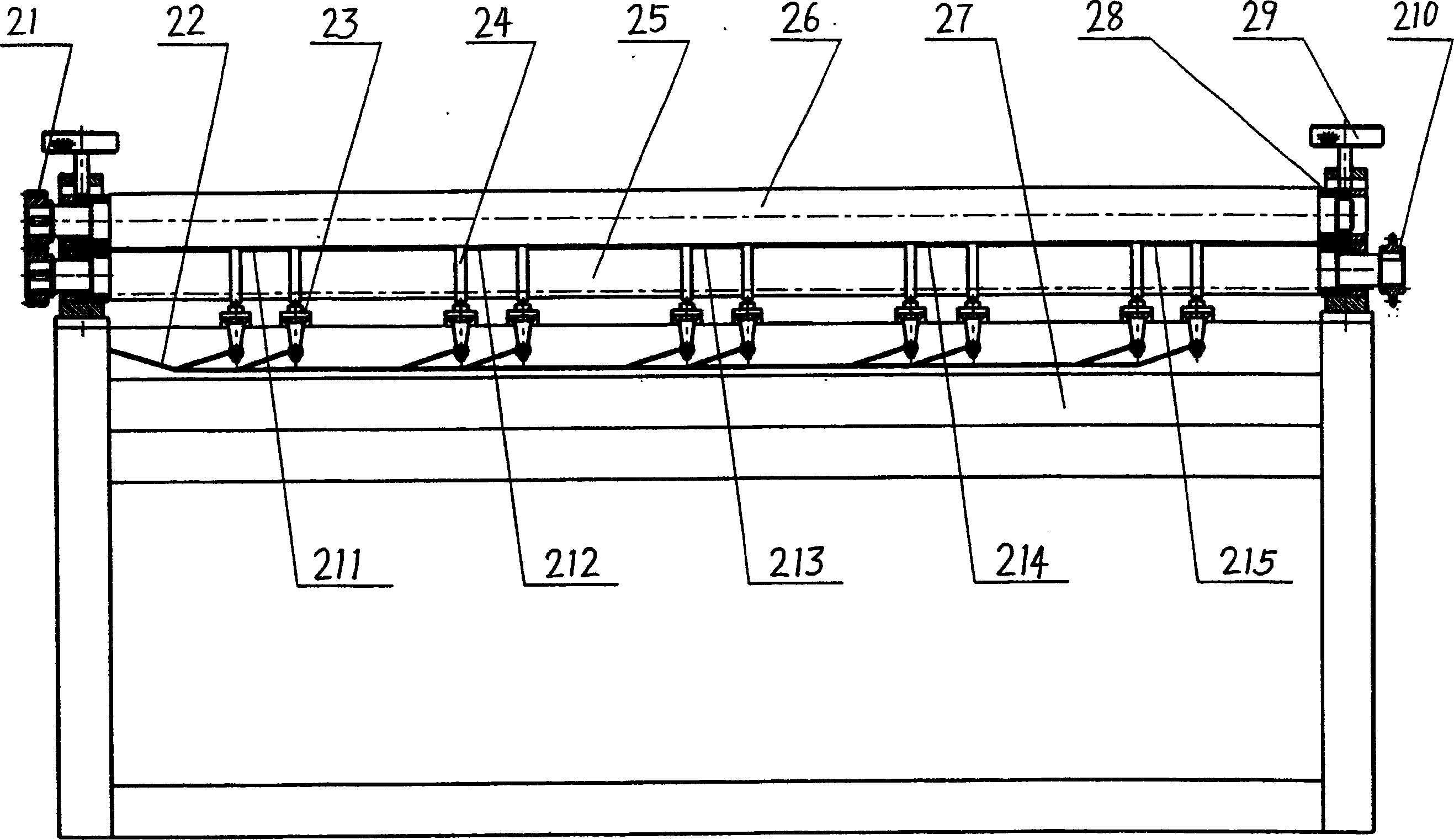

[0020] Such as figure 2 , wherein the detection system 15 is mainly composed of a detection frame 27, a detection shaft 25 mounted on the detection frame 27 through a bearing, and a pressing shaft 26 above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com