Continuous-flow drinking fluid dispenser

A technology of fluid distributor and distributor, which is applied in the direction of liquid distribution, distribution device, liquid distribution, transportation or transfer device, etc., which can solve the problems of weakening operation reliability, increasing manufacturing and assembly costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

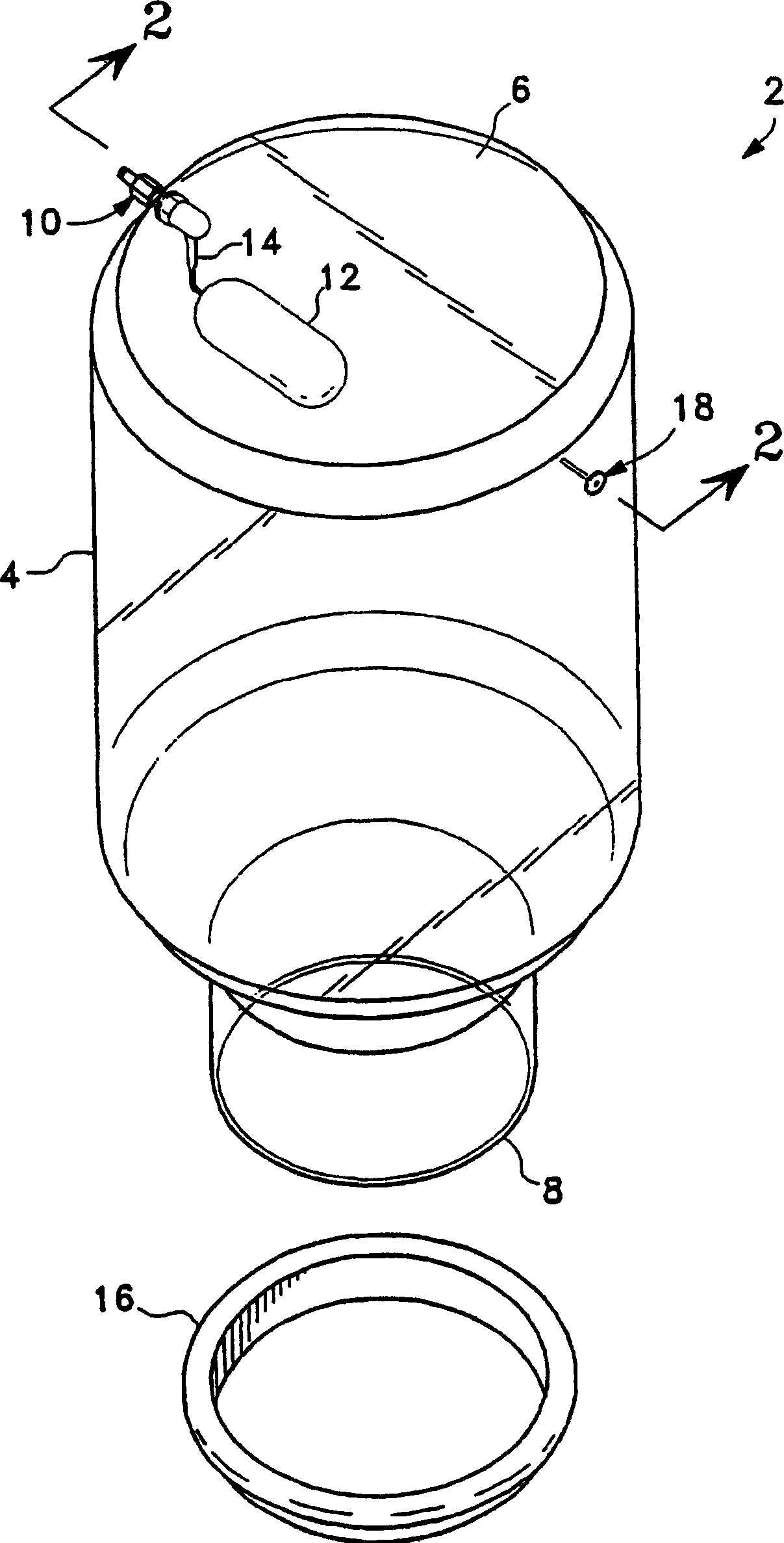

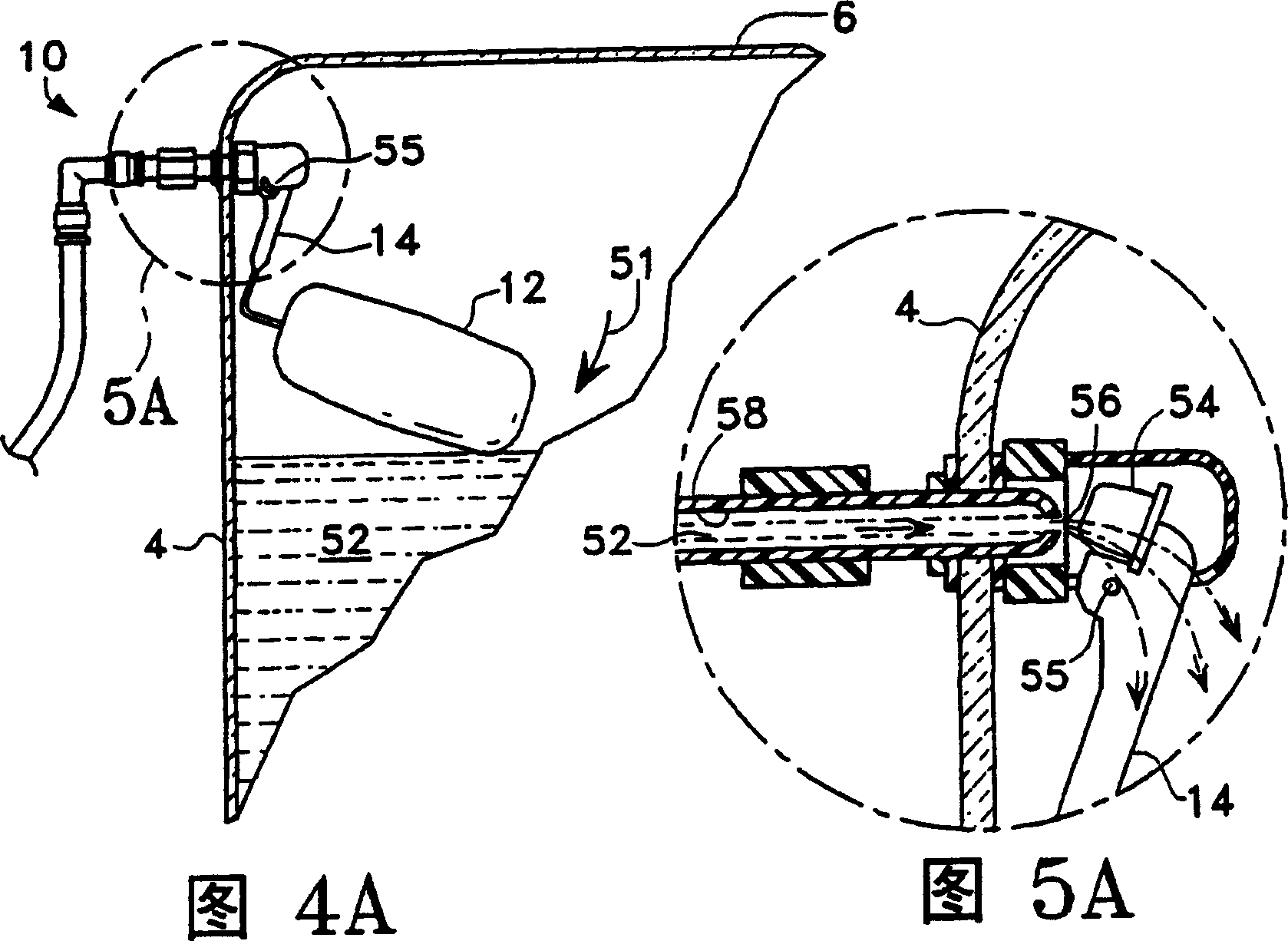

[0028] now refer to figure 1 , in which is shown an exploded view of the main components of a first embodiment of the invention, generally designated 2 . The assembly 2 of this embodiment includes a water bottle 4 having an open end 8 and a closed end 6 . Preferably, the water bottle 4 is made of transparent material such as transparent plastic or glass. A fluid valve 10 is provided in the bottle 4 which is actuated by a float 12 via an actuating arm 14 . Fluid valve 10 may draw water from a continuous water source, such as a building's water mains (not shown). Preferably, water from said source passes through a series of filters (not shown) before entering fluid valve 10 . The purification process may be reverse osmosis, or carbon block filtration, which is well known in the art.

[0029] A gasket 16 is located at the open end 8 of the bottle 4 . Preferably, the gasket 16 is made of a resilient material such as rubber or Teflon (Teflon) made. The gasket 16 can be pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com