Twin shaft flexible roll-bending machine based on control of feeding force

A technology of feed force and roll bending machine, which is applied in the field of tube forming equipment and pipe fittings, can solve the problems of uneven material in the working part of the elastic wheel, affecting the forming accuracy of the working section, and different axial forces, etc., to improve the international Competitiveness, simple structure, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

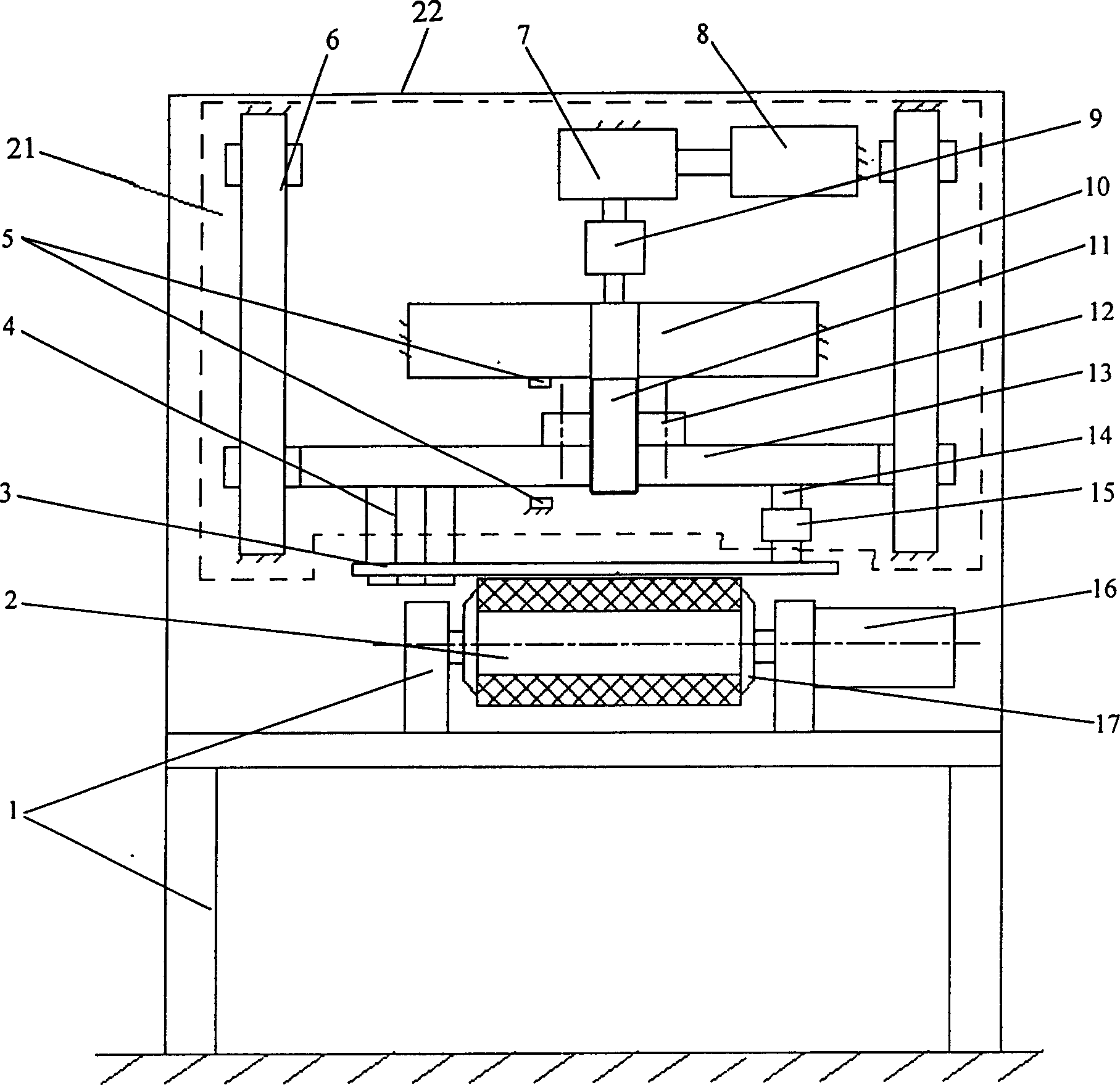

[0024] Such as figure 1 shown.

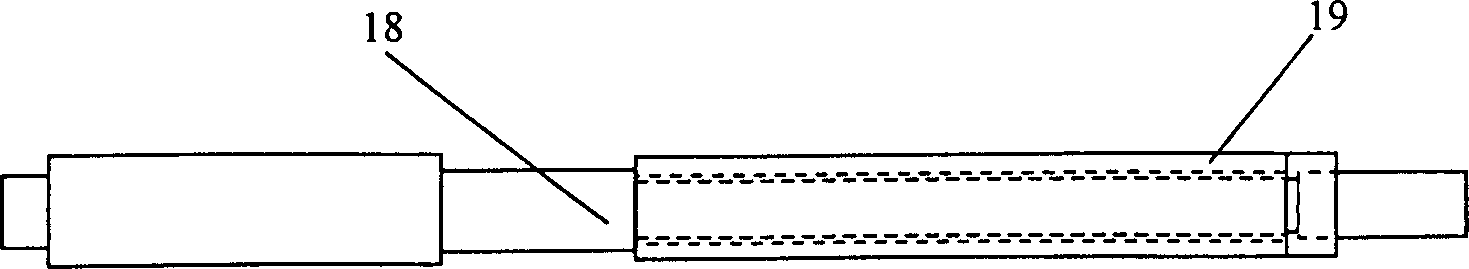

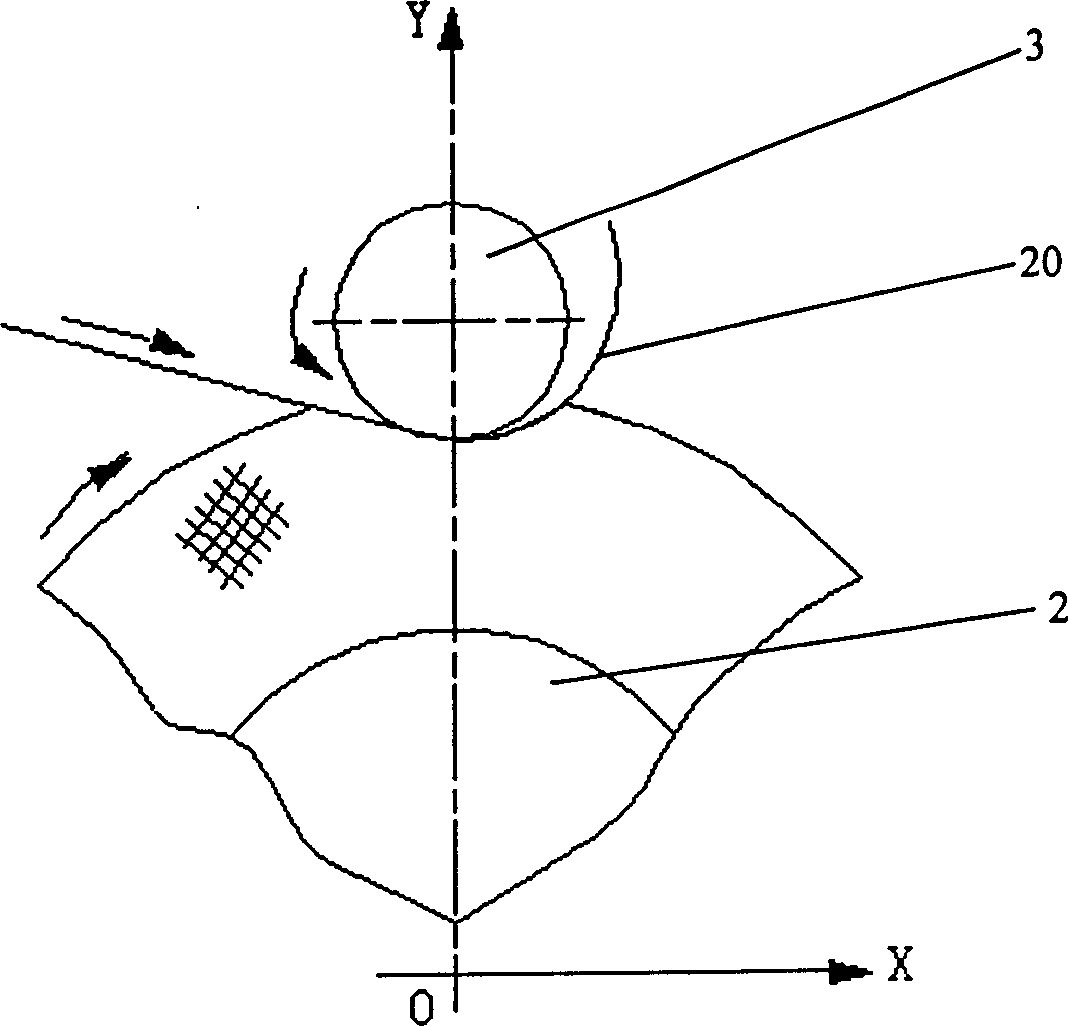

[0025] A two-axis flexible roll bending machine based on feed force control, including a frame 1, a driving roller 2, and a driven roller 3, the driving roller 2 is connected to the frame 1, and the driving wheel 2 is connected to a driving roller driving device 16 The driven roller 3 is connected with the longitudinal driving device 21, the longitudinal driving device 21 and the frame 1 are installed in the casing 22, and the processed workpiece 20 is located between the driving roller 2 and the driven roller 3 and between them Bending and forming under the joint action, the driving roller 2 is composed of a rigid mandrel and an elastic body covered on the rigid mandrel; one end of the driven roller 3 is installed on the support 4 in the longitudinal driving device 21, and the support 4 Connected to one end of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com