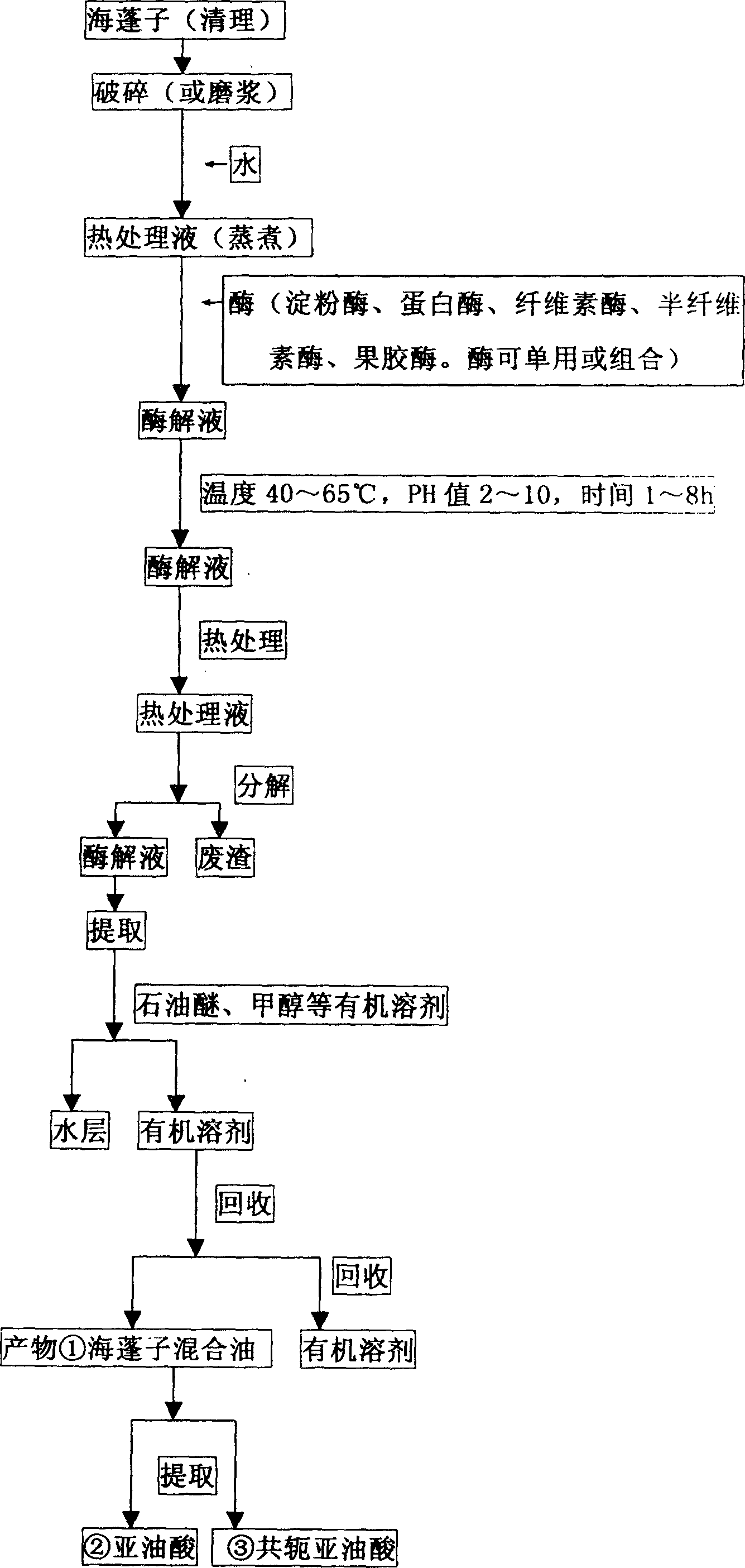

Process of extracting glasswort oil from glasswort plant

A technology for plant extraction and samphire, applied in the field of samphire oil extraction, can solve the problems of intensified denaturation of linoleic acid and conjugated linoleic acid, impact on utilization, low extraction rate of samphire oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Take the dried Salicornia plant, crush it, add water 3 times the weight of the raw material, heat and cook for 1 hour after fully stirring, and when it is allowed to cool to 50°C, add 0.5% of the original weight of protease to adjust the pH value to 5.0, and then keep the temperature at Enzymatic hydrolysis at 55°C for 5 hours. After enzymolysis, heat it at 100°C and filter for 30 minutes, take the enzymolysis solution and add petroleum ether for extraction, and recover petroleum ether to obtain samphire oil.

Embodiment 2

[0014] Take 2 kg of dry samphire seeds, add 5 kg of water, heat and cook for 2 hours after fully stirring, add 5 grams of protease, 5 grams of cellulase, and 5 grams of pectinase when cooled to 60 ° C, adjust the pH value to 5.5, and then keep Enzymolysis was carried out at 60°C for 6 hours. After enzymolysis, heat it at 90°C to filter the precipitate for 45 minutes, take the enzymolysis solution and add methanol for extraction, and recover methanol to obtain Salicornia oil.

Embodiment 3

[0016] Take 1 kg of salicornia oil, add 10 grams of linoleic acid isomerase (Lactobacillus Yeuferi PYR8 (Atcc 55739)), adjust the pH value to 7, and cultivate it for 42 hours at 35-37°C, and the salicornia oil can be extracted The linoleic acid is converted into conjugated linoleic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com