Recombinant processing method for naphtha

A treatment method and naphtha technology, which is applied in the treatment of naphtha and the petroleum industry, etc., and can solve problems such as coking of furnace tubes and failure of ethylene steam cracking equipment to operate normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

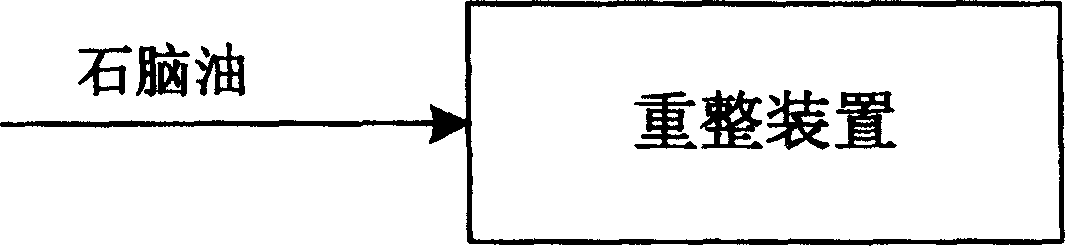

Image

Examples

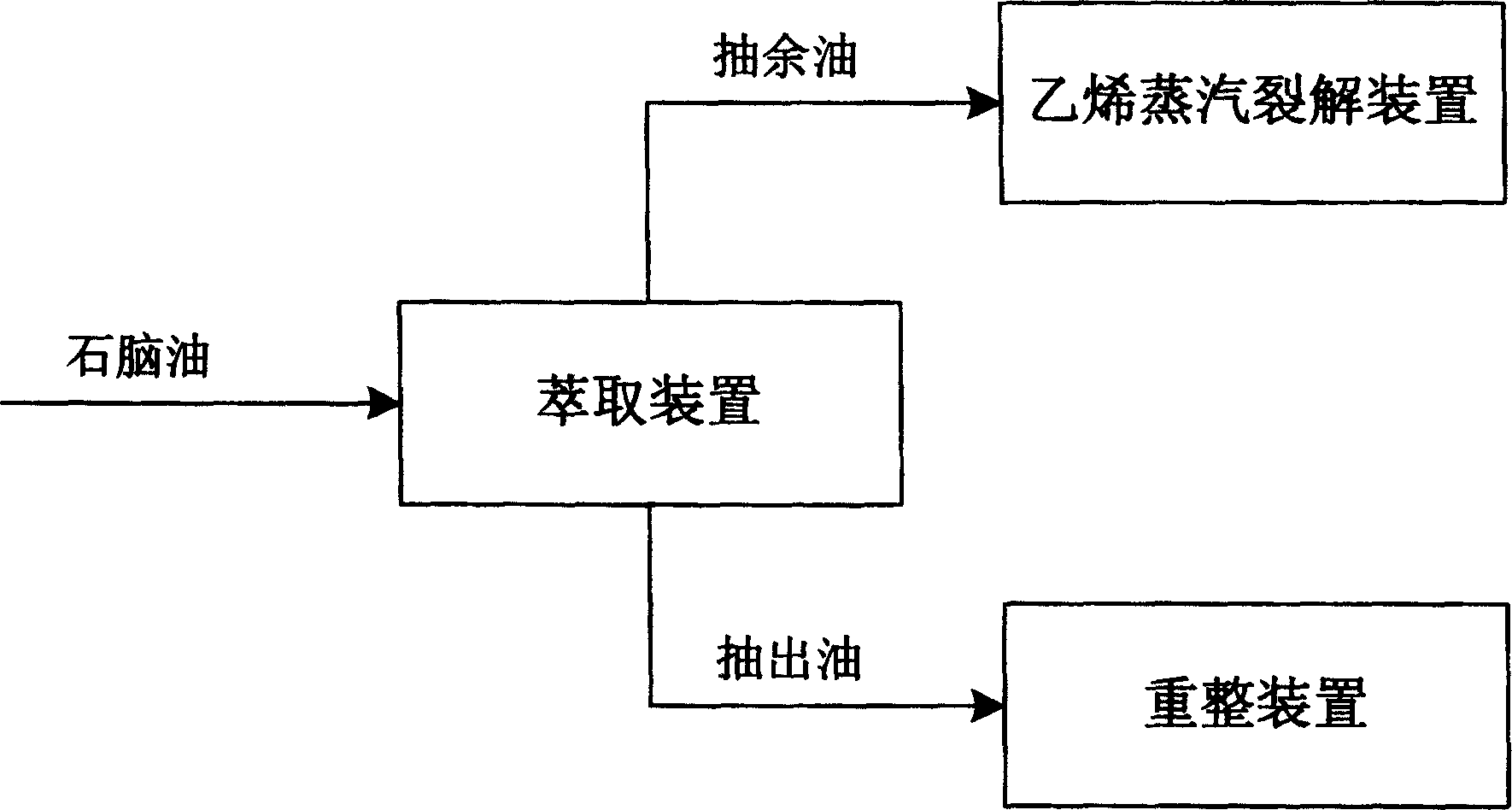

Embodiment 1

[0028] Such as image 3 As shown, the density is 735 kg / m3, the distillation range is 80-165°C, the alkane content is 56% (Wt.), the cycloalkane content is 41% (Wt.), and the aromatic content is 3% (Wt.) The naphtha enters the extraction unit, the feed rate is 2 kg / hour, the solvent used is N-methylpyrrolidone, the solvent contains water 3% (Wt.), the solvent ratio is 8: 1 (Wt.), and the operating temperature is 120 °C, the operating pressure is 0.6MPa; the flow rate of raffinate is 1.15 kg / hour, the density is 667 kg / m3, the distillation range is 80-163 °C, and the composition is 95.40% (Wt.) of alkanes and 4.42% of naphthenes (Wt.), aromatics 0.18% (Wt.); the flow rate of the extracted oil is 0.85 kg / hour, the density is 798 kg / m3, the distillation range is 80 to 168 ° C, and the composition is alkane 2.36% (Wt.), 90.80% (Wt.) of naphthenes, 6.84% (Wt.) of aromatics. The obtained raffinate oil enters the ethylene steam cracking furnace in Comparative Example 2; the obtaine...

Embodiment 2

[0038] Naphtha with a density of 724 kg / m3, a distillation range of 70-171°C, an alkane content of 65% (Wt.), a naphthene content of 31% (Wt.), and an aromatic content of 4% (Wt.) The oil enters the extraction unit, the feed rate is 2 kg / hour, the solvent used is dimethyl sulfoxide, the solvent contains 5% water (Wt.), the solvent weight ratio is 7: 1, the operating temperature is 95 ° C, and the operating pressure is 0.7 MPa; the flow rate of raffinate is 1.332 kg / hour, the density is 695 kg / m3, the distillation range is 68~163°C, and it consists of alkanes 96.10% (Wt.), naphthenes 3.75% (Wt.), aromatics 0.15% (Wt.). The flow rate of the extracted oil is 0.668 kg / hour, the density is 789 kg / m3, the distillation range is 71~168°C, and the composition is 3.00% (Wt.) of alkanes, 85.33% (Wt.) of naphthenes, and 11.68% of aromatics ( Wt.). The obtained raffinate oil enters the ethylene steam cracking furnace in Comparative Example 4; the obtained extracted oil enters the reformi...

Embodiment 3

[0048] Naphtha with a density of 738 kg / m3, a distillation range of 75 to 172°C, an alkane content of 39.5% (Wt.), a naphthene content of 55.3% (Wt.), and an aromatic content of 5.2% (Wt.) Oil enters extraction unit, and feed rate is 2 kilograms / hour, and used solvent is sulfolane, and solvent contains water 0.5% (Wt.), and solvent weight ratio is 11: 1, and operating temperature is 128 ℃, and operating pressure is 1.0MPa; The flow rate of the oil is 0.83 kg / hour, the density is 688 kg / m3, the distillation range is 73-170°C, and the composition is 93.98% (Wt.) of alkanes, 4.82% (Wt.) of naphthenes, and 1.20% (Wt.) of aromatics .). The flow rate of the extracted oil is 1.17 kg / hour, the density is 793 kg / m3, the distillation range is 71~174°C, and the composition is 0.85% (Wt.) of alkanes, 91.11% (Wt.) of naphthenes, and 8.04% of aromatics ( Wt.). The obtained raffinate oil enters the ethylene steam cracking furnace in Comparative Example 6; the obtained extracted oil enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com