Inorganic inducing treatment for reverse osmosis concentrate

A technology of reverse osmosis concentrate and treatment method, which is applied in the field of waste water treatment in environmental science, can solve the problems such as unusable, and achieve the effects of low cost in the treatment process, improved water recovery rate, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

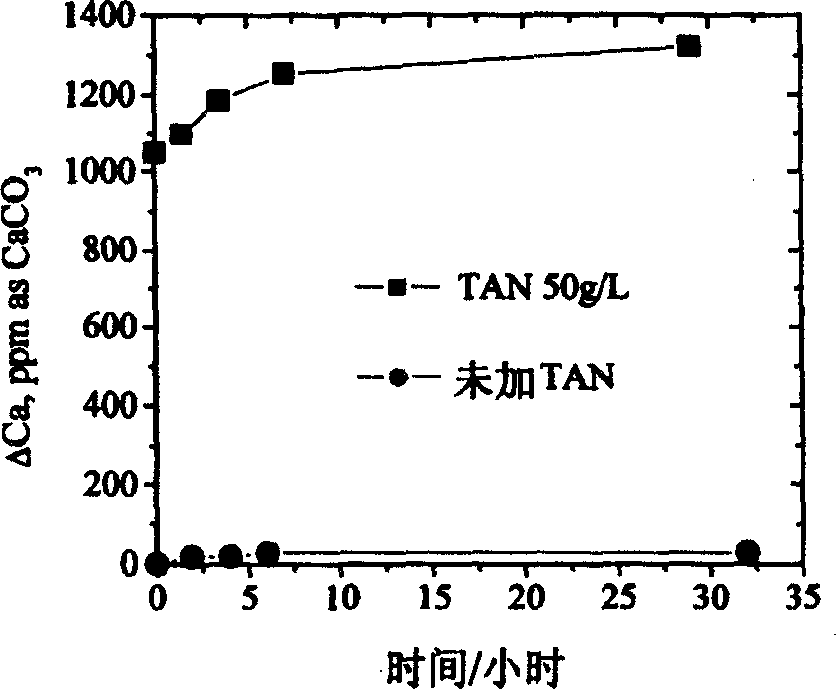

[0016] Simulate the concentrate with 88% recovery rate of a desalination plant, weigh NaCl, MgCl 2 , CaCl 2 , NaHCO 3 , mixed with distilled water, placed in a 1L flask, and added 25ppm antiscalant C to make a concentrated solution, in which Ca 2+ = 680ppm, Mg 2+ =540ppm, Na + =2780ppm, HCO 3 - =2890ppm, Cl - = 4880ppm. The concentrate had a pH of 7.9 and an LSI of 2.7. Add 50 grams of inorganic inducer TAN, place the flask in a shaker with a constant temperature water bath, and shake and mix for 29 hours. During this period, samples were taken several times for analysis of solution pH, conductivity, turbidity, ion concentration, etc.

[0017] After the concentrate is treated, 200mg / L of aluminum sulfate is added for coagulation and filtration to obtain the treated concentrate. When coagulating, coagulate at 300 rpm for half a minute, then at 50 rpm for 5 minutes.

[0018] After the induction treatment, the calcium ion in the concentrated solution was reduced by 130...

Embodiment 2

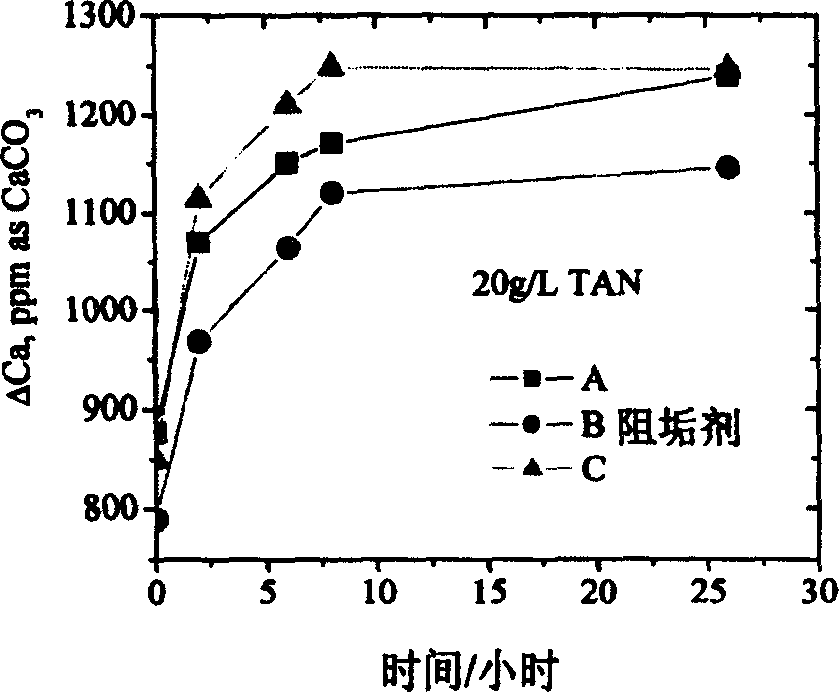

[0021] Weigh NaCl, MgCl 2 , CaCl 2 , NaHCO 3 , mixed with distilled water, put into three 1L flasks, and added 25ppm of three different types of commonly used scale inhibitors A, B, C (they contain -COOH, -PO 3 h 2 ,-OH,-SO 3 H, -COOR group), made into concentrated solution, in which Ca 2+ = 680ppm, Mg 2+ =540ppm, Na + =2780ppm, HCO 3 - =2890ppm, Cl - = 4880ppm. Add inducer TAN20g / L, shake and mix in constant temperature water bath for 26 hours.

[0022] After the concentrate is treated, 200mg / L of aluminum sulfate is added for coagulation and filtration to obtain the treated concentrate. When coagulating, coagulate at 300 rpm for half a minute, then at 50 rpm for 5 minutes.

[0023] The analysis results of calcium ions changing with time are as follows: figure 2 shown. From figure 2 It can be seen that 20g / LTAN can effectively induce the deposition of calcium ions, and 67%-73% of the calcium ions in the concentrated solution are induced to deposit, and the in...

Embodiment 3

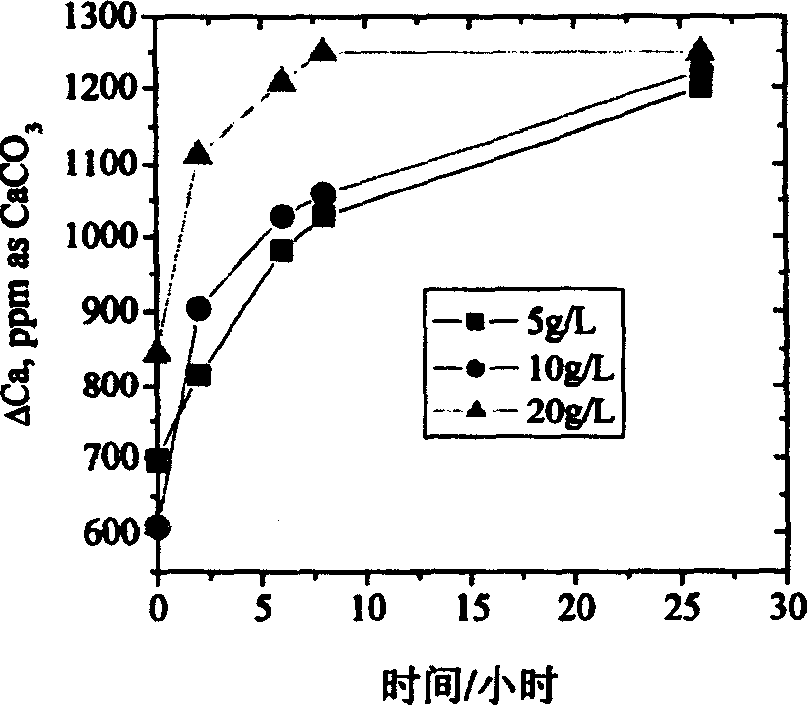

[0026] Weigh NaCl, MgCl 2 , CaCl 2 , NaHCO 3 , mixed with distilled water, put into three 1L flasks, and added 25ppm antiscalant C respectively to make a concentrated solution, in which Ca 2+ = 680ppm, Mg 2+ =540ppm, Na + =2780ppm, HCO 3 - =2890ppm, Cl - = 4880ppm. Add inducer TAN 5g / L, 10g / L, 20g / L respectively, shake and mix in constant temperature water bath for 26 hours.

[0027] After the concentrate is treated, 200mg / L of aluminum sulfate is added for coagulation and filtration to obtain the treated concentrate. When coagulating, coagulate at 300 rpm for half a minute, then at 50 rpm for 5 minutes.

[0028] The analysis results of calcium ions changing with time are as follows: image 3 shown. From image 3 It can be seen that after 26 hours of induction reaction, the three concentrations of inducers can effectively induce the deposition of calcium ions, and the deposition rates of calcium ions in the concentrated solution are 70.6%, 71.9%, and 73.4%, respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com