Natural edible raw material artificial engineering rice and its special equipment and producing method

A raw material and artificial technology, applied in the field of natural edible raw material artificial engineered rice, can solve the problems of inability to obtain products with complex and peculiar shapes, inability to process and produce artificial rice, frictional heat cannot be eliminated in time, etc., to achieve unreasonable changes in diet , Conducive to the adjustment of the body, the effect of attractive shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

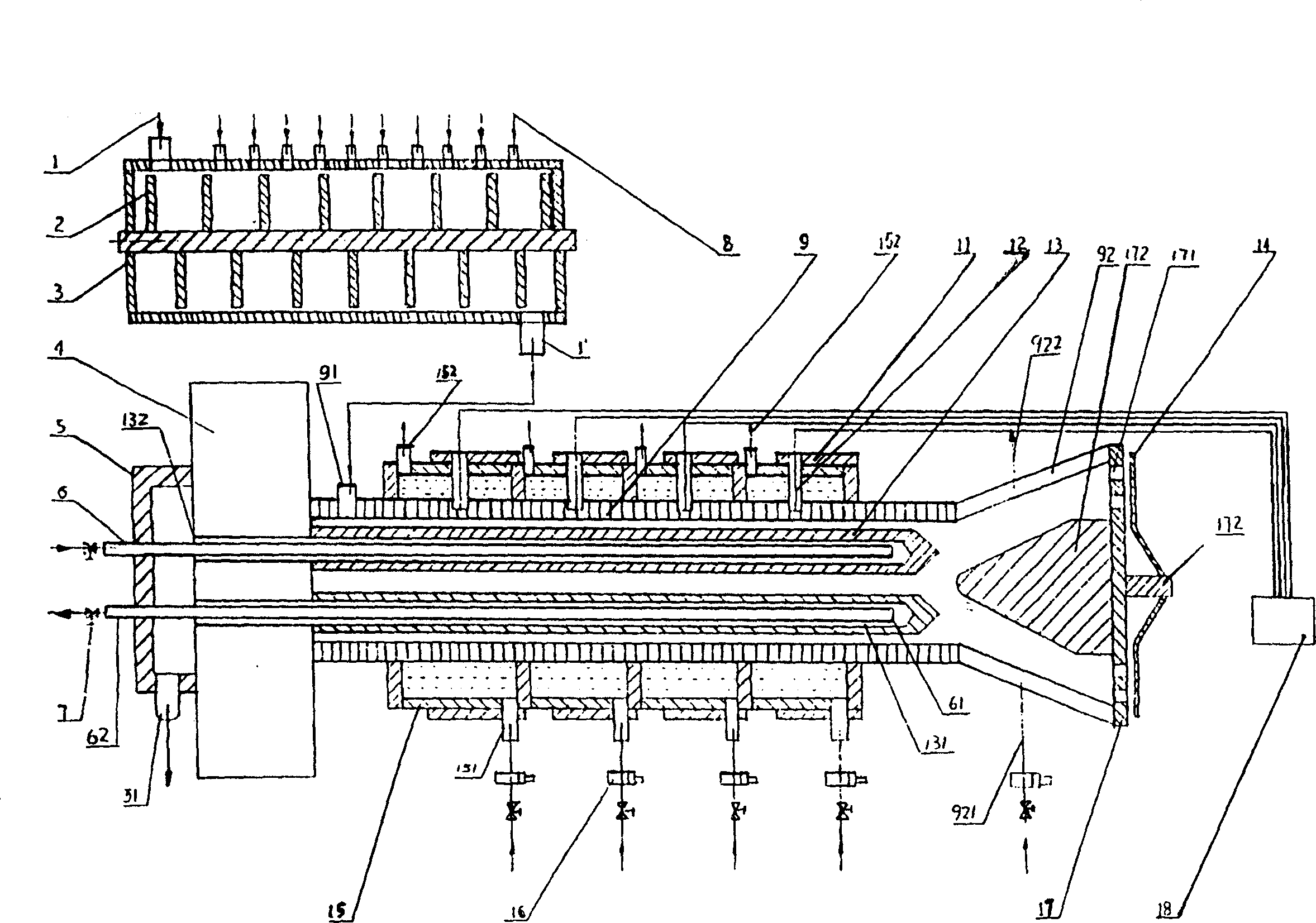

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of artificial engineering rice by natural edible raw material, the weight (kilogram) of various raw materials is:

[0038] Corn flour 35 Rice flour 20 Glutinous rice flour 15 Jerusalem artichoke flour 20

[0039] Apple Juice 5 Xylitol 0-2 Cooking Oil 2 Water 5

[0040] The manufacture method of described natural edible raw material artificial engineering rice is as follows:

[0041] (1) Raw material preparation: commercially purchase high-quality raw materials that meet national standards:

[0042] (2) Mixing: mix the above-mentioned various starch raw material powders with water evenly, stir for 10 minutes, add auxiliary materials such as apple juice, and stir for another 15 minutes;

[0043] (3) Semi-gelatinization: Cook at 50-60°C for 10-20 minutes to make the mixture semi-gelatinized;

[0044] (4) Extrusion molding: then extrude at 70-80°C and 30-70MPa pressure, granulate, and shape;

[0045] (5) Drying: Dry at 80-90°C for 1-2 hours.

Embodiment 2

[0046] Embodiment 2: a kind of artificial engineering rice by natural edible raw material, the weight (kilogram) of various raw materials is:

[0047] Pumpkin Flour 35 Corn Flour 20 Glutinous Rice Flour 15 Rice Flour 20

[0048] Orange Juice 5 Xylitol 2 Cooking Oil 2 Water 5-10

[0049] The manufacture method of described natural edible raw material artificial engineering rice is as follows:

[0050] (1) Raw material preparation: commercially purchase high-quality raw materials that meet national standards;

[0051] (2) Mixing: mix the above-mentioned various starch raw material powders with water evenly, stir for 10 minutes, add orange juice and other auxiliary materials, and stir for another 15 minutes;

[0052] (3) Semi-gelatinization: Cook at 50-60°C for 10-20 minutes to make the mixture semi-gelatinized;

[0053] (4) Extrusion molding: then extrude at 70-80°C and 30-70MPa pressure, granulate, and shape;

[0054] (5) Drying: Dry at 80-90°C for 1-2 hours.

Embodiment 3

[0055] Embodiment 3: a kind of artificial engineering rice by natural edible raw material, the weight (kilogram) of various raw materials is:

[0056] Sweet Potato Flour 35 Corn Flour 20 Glutinous Rice Flour 15 Northeast Rice Flour 25

[0057] Apple Juice 5 Xylitol 0-2 Edible Oil 2 Water 0-5

[0058] The manufacture method of described natural edible raw material artificial engineering rice is as follows:

[0059] (1) Raw material preparation: commercially purchase high-quality raw materials that meet national standards;

[0060] (2) Mixing: mix the above-mentioned various starch raw material powders with water evenly, stir for 10 minutes, add apple juice, etc., and stir for another 15 minutes;

[0061] (3) Semi-gelatinization: Cook at 50-60°C for 10-20 minutes to make the mixture semi-gelatinized;

[0062] (4) Extrusion molding: then extrude at 70-80°C and 30-70MPa pressure, granulate, and shape;

[0063] (5) Drying: Dry at 80-90°C for 1-2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com