Method for making grid and MOS transistor

An oxide semiconductor, metal silicide layer technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

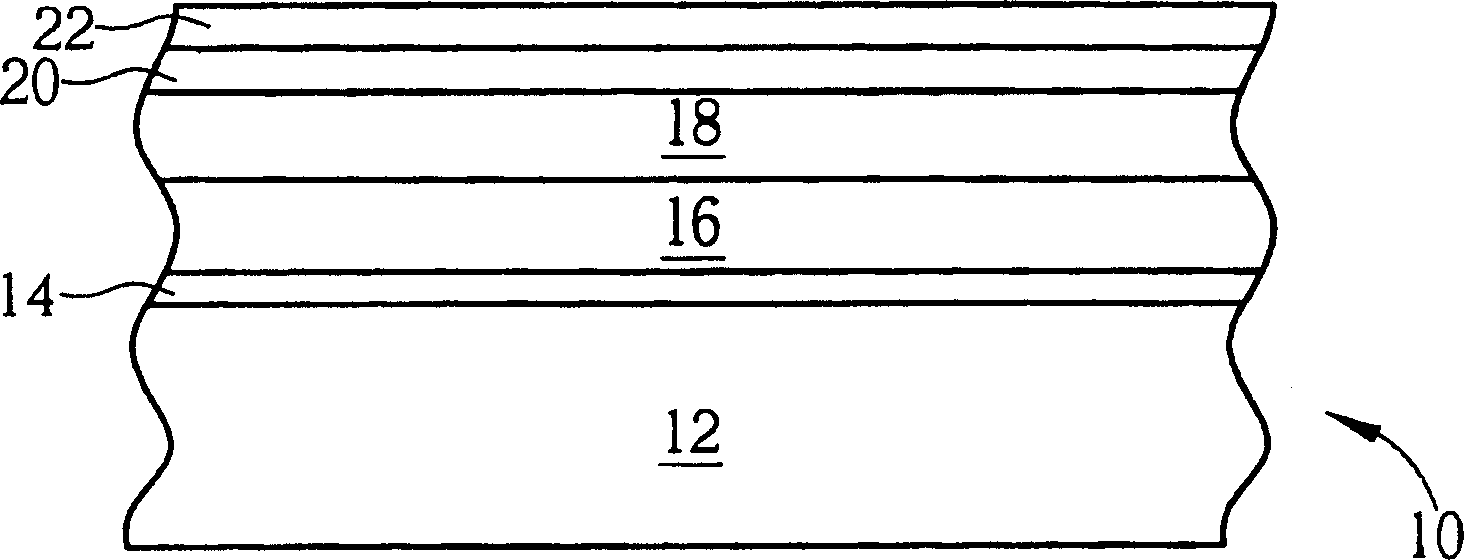

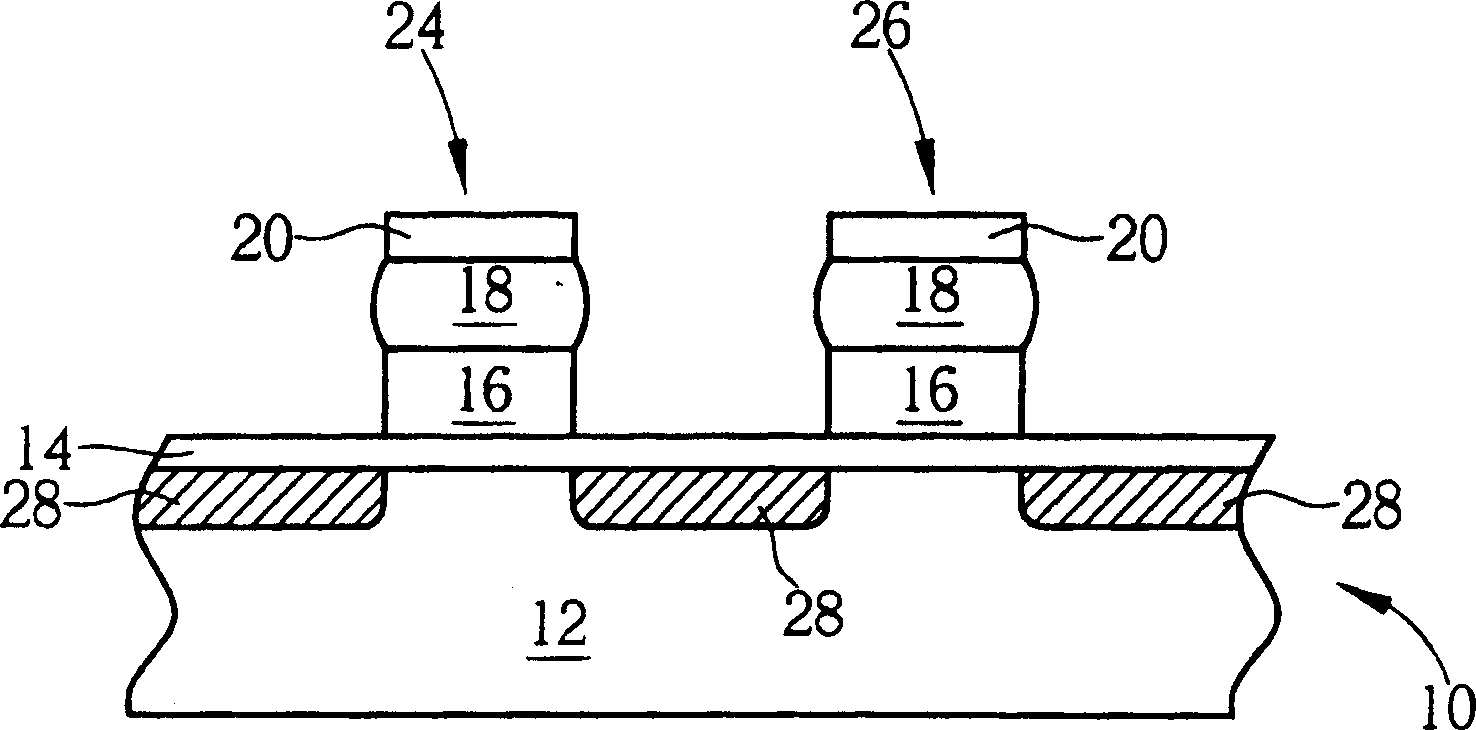

[0039]Please refer to Figure 5 to Figure 9 , Figure 5 to Figure 9 It is a schematic diagram of the process of fabricating a gate on a semiconductor chip 70 according to the present invention. Such as Figure 5 As shown, the present invention first forms a first oxide layer 74 as a gate oxide layer on the surface of the silicon substrate 72 of the semiconductor chip 70, and then sequentially forms a doped polysilicon layer 76, a metal silicide layer on the first oxide layer 74. object layer 78 , a mask layer 80 and a photoresist layer 82 . Wherein, the oxide layer 74 is made of silicon dioxide, the mask layer 80 is made of silicon nitride compound, and the metal silicide layer 78 is made of tungsten silicide (WSi x ).

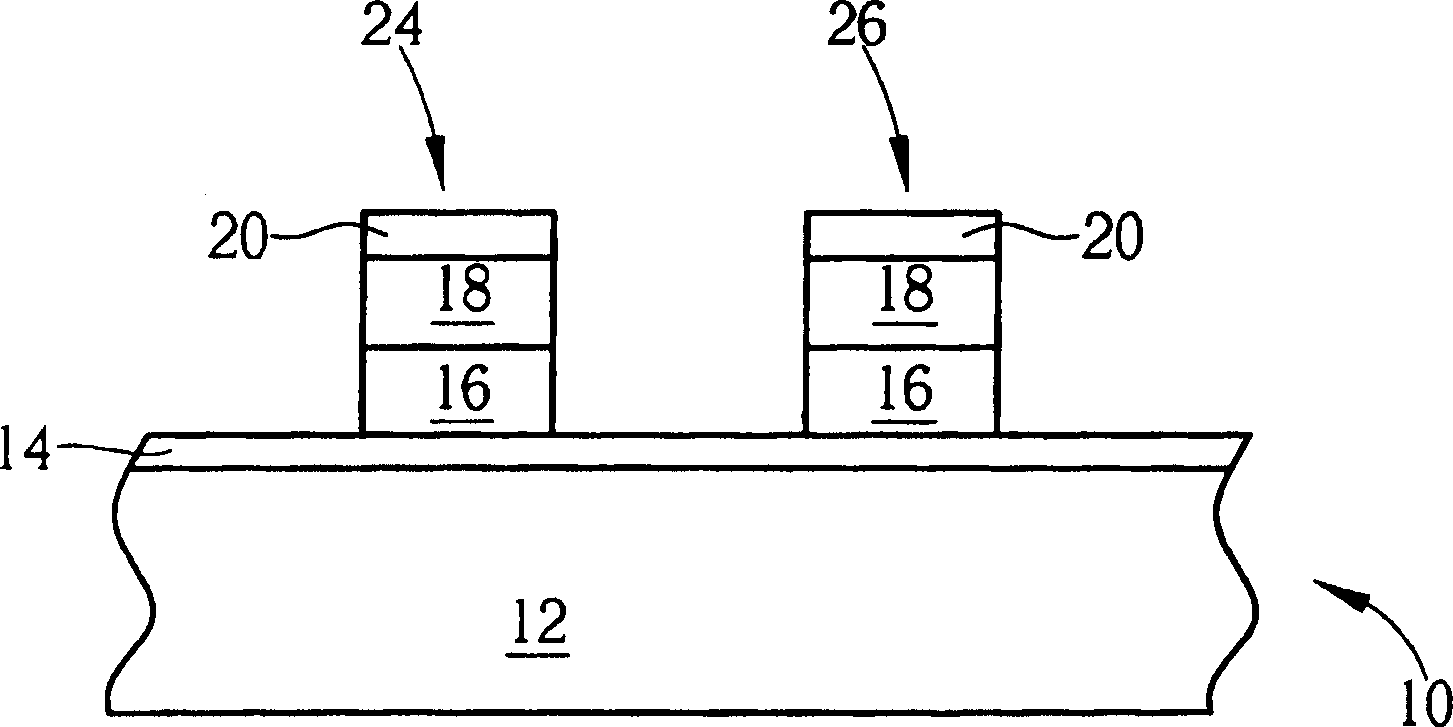

[0040] Such as Figure 6 As shown, a photolithographic etching (yellow light) process is then performed to define the pattern of the gate in the photoresist layer 82 . Etching is then performed using the pattern of the photoresist layer 82 to remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com