Wafer electroplating device and method

An electroplating device and wafer technology, applied in the direction of circuits, electrolytic components, electrical components, etc., can solve problems such as escape, and achieve the effects of easy control of the gap, prevention of gas leakage, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The following are only specific examples, and are described in detail with diagrams, so as to have a further understanding and understanding of the various functions and characteristics of this creation:

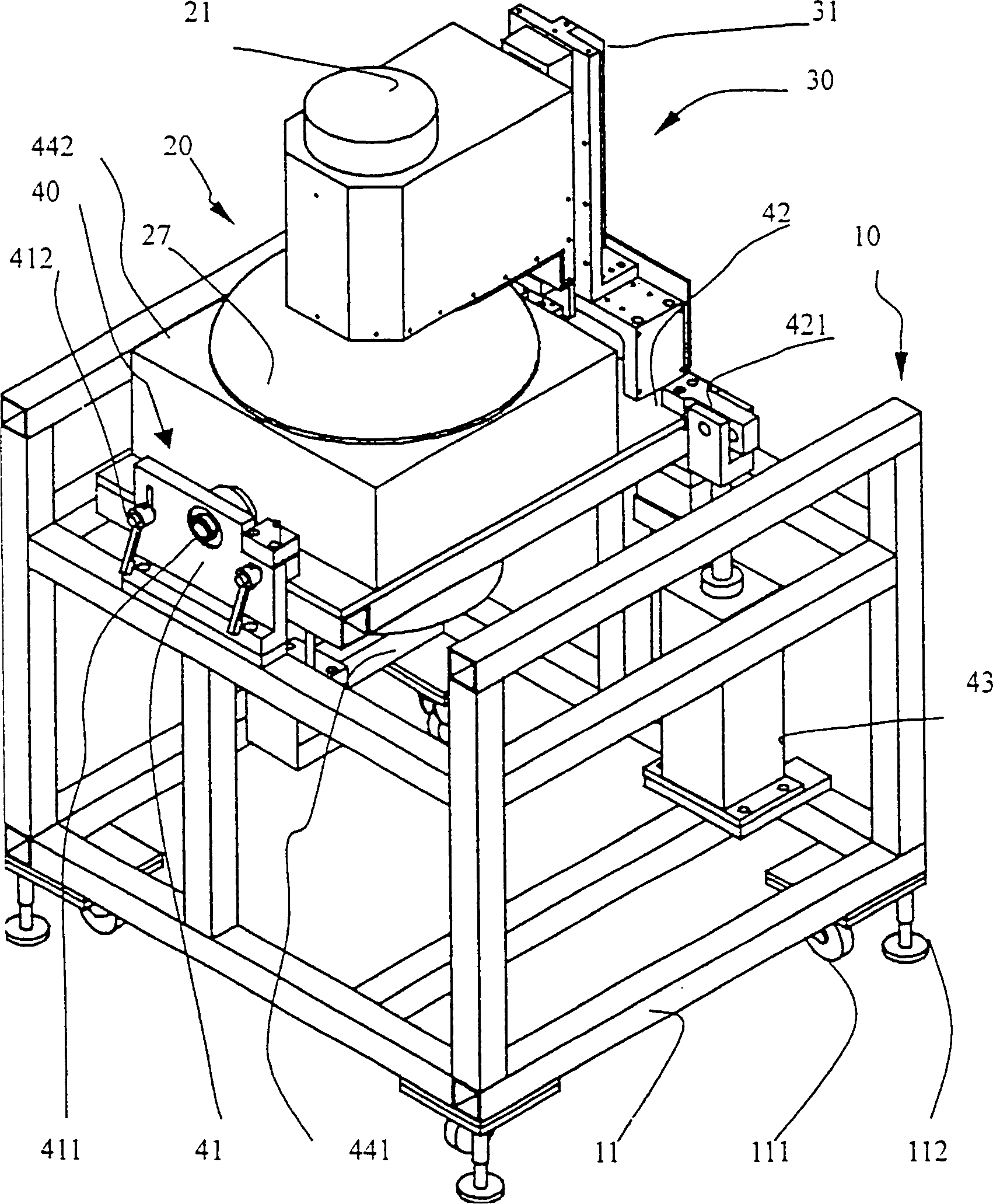

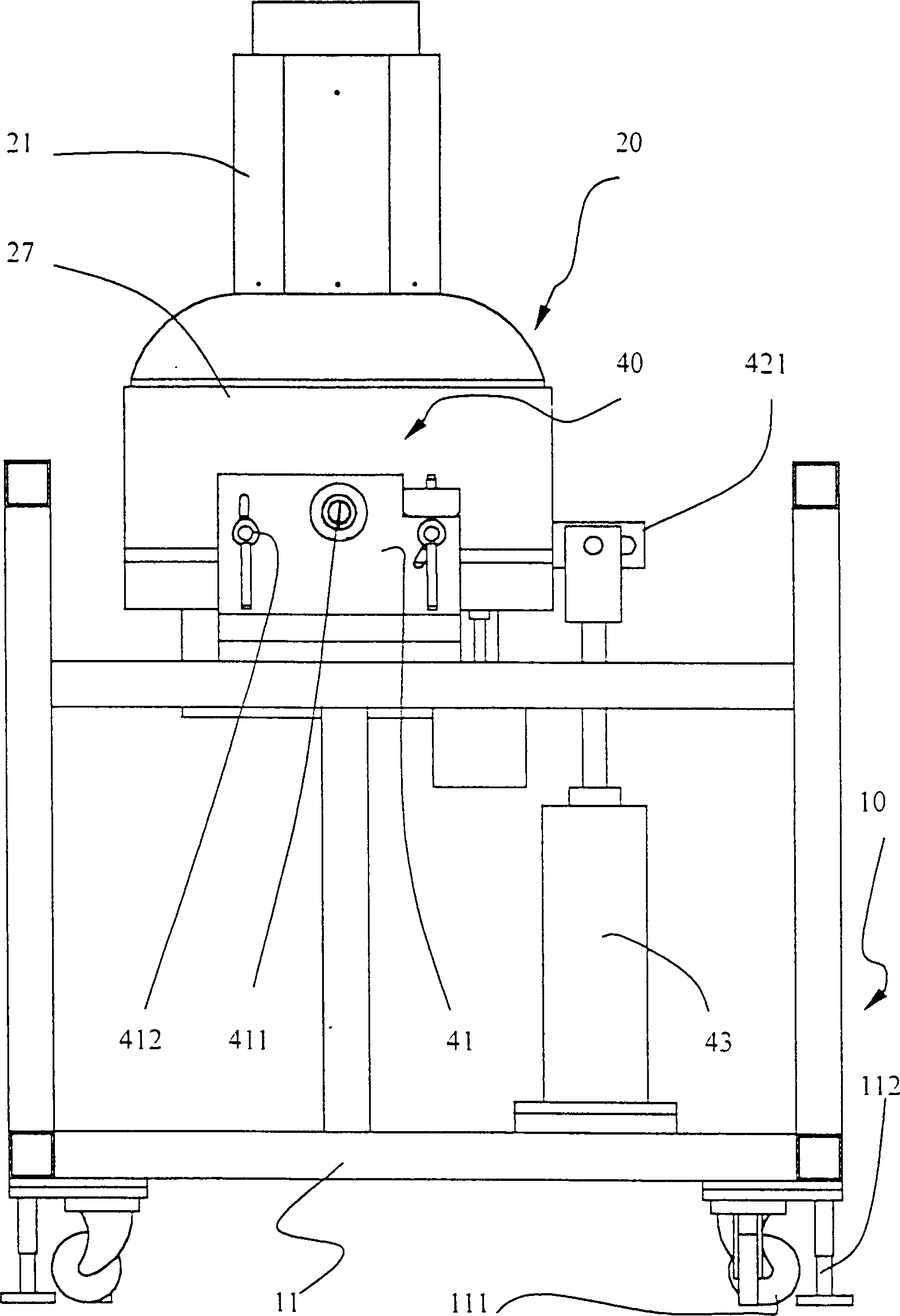

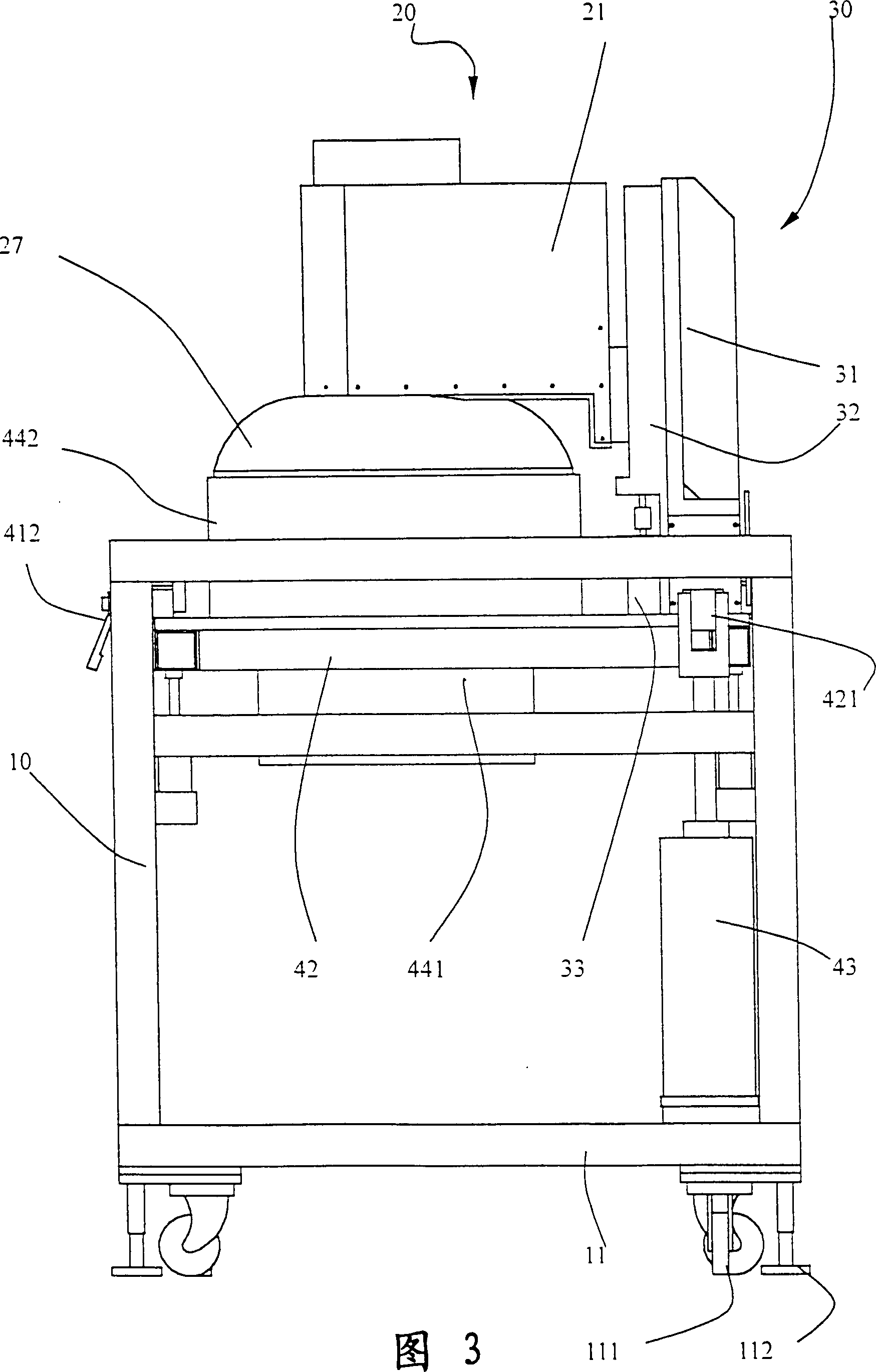

[0074] Such as Figure 1~4 Shown, the electroplating device structure of the present invention comprises:

[0075] The frame main body module 10 is provided with a frame body 11 that can be placed stably for the assembly of the main constituent modules. Nearly four corners of the frame body 11 are provided with wheel bodies 111 and adjustable support The column 112 enables the frame body 11 to be slidable and fixed, and the frame body 11 is also provided with related pipeline units and control units;

[0076] The wafer rotation module 20 is provided with a housing 21 for one side to be connected with the vertical upper and lower modules 30, and a wafer rotation mechanism is set in the housing 21, and the wafer rotation mechanism is composed of a pneumatic rotary join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com