Colour image sensor and driving method thereof

A color image and sensor technology, applied in color TV, color TV parts, instruments, etc., can solve problems such as low image resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

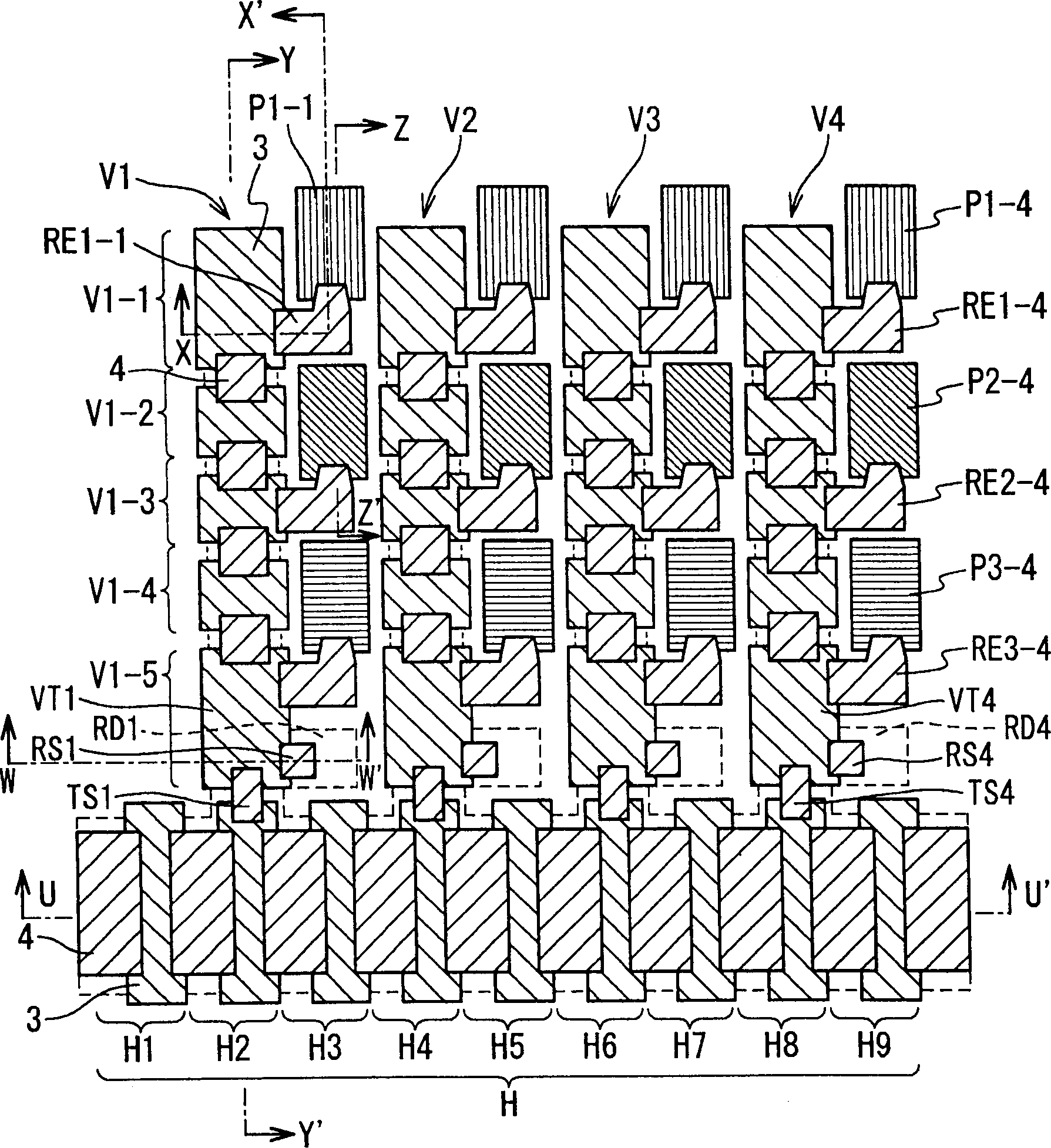

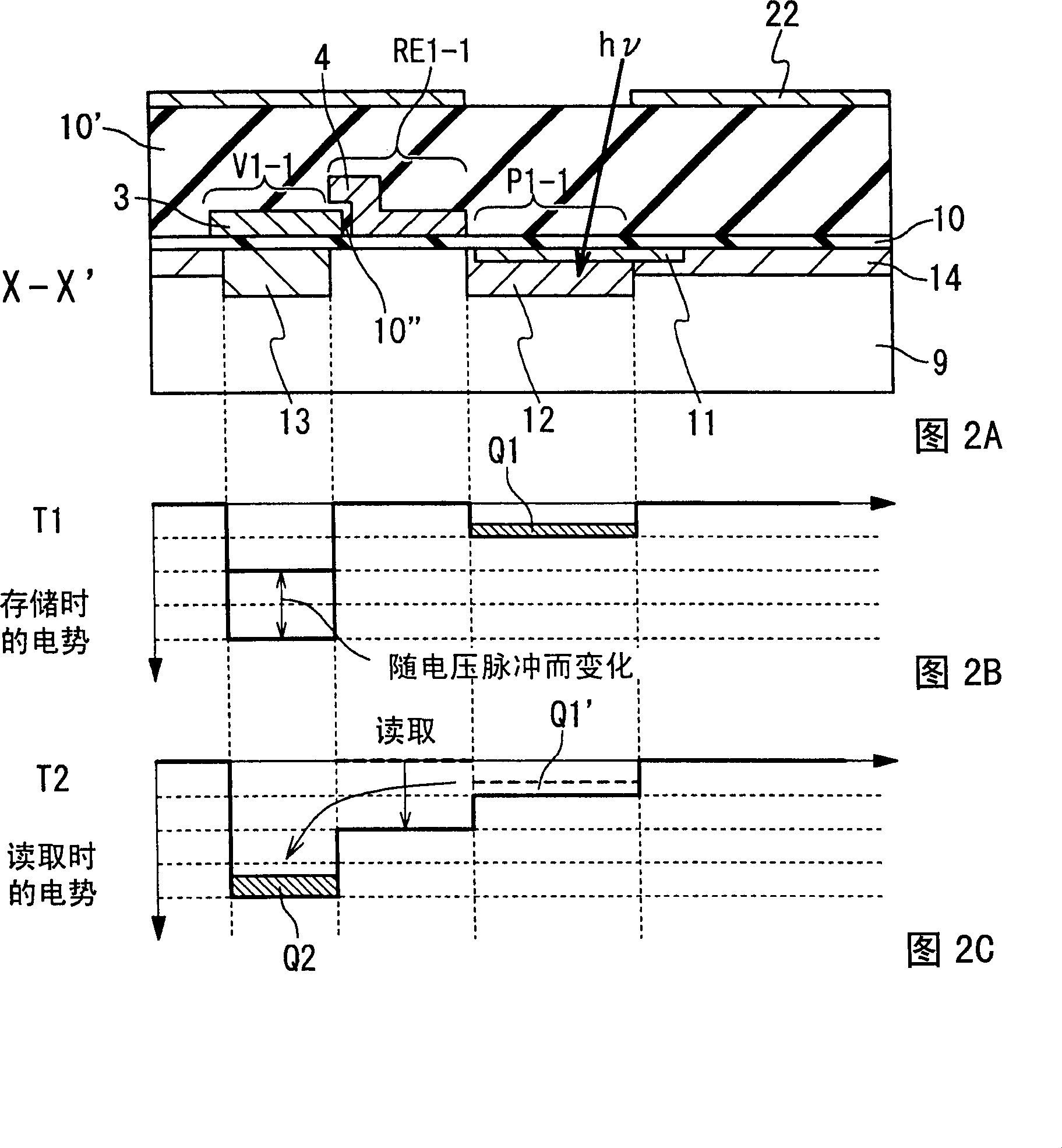

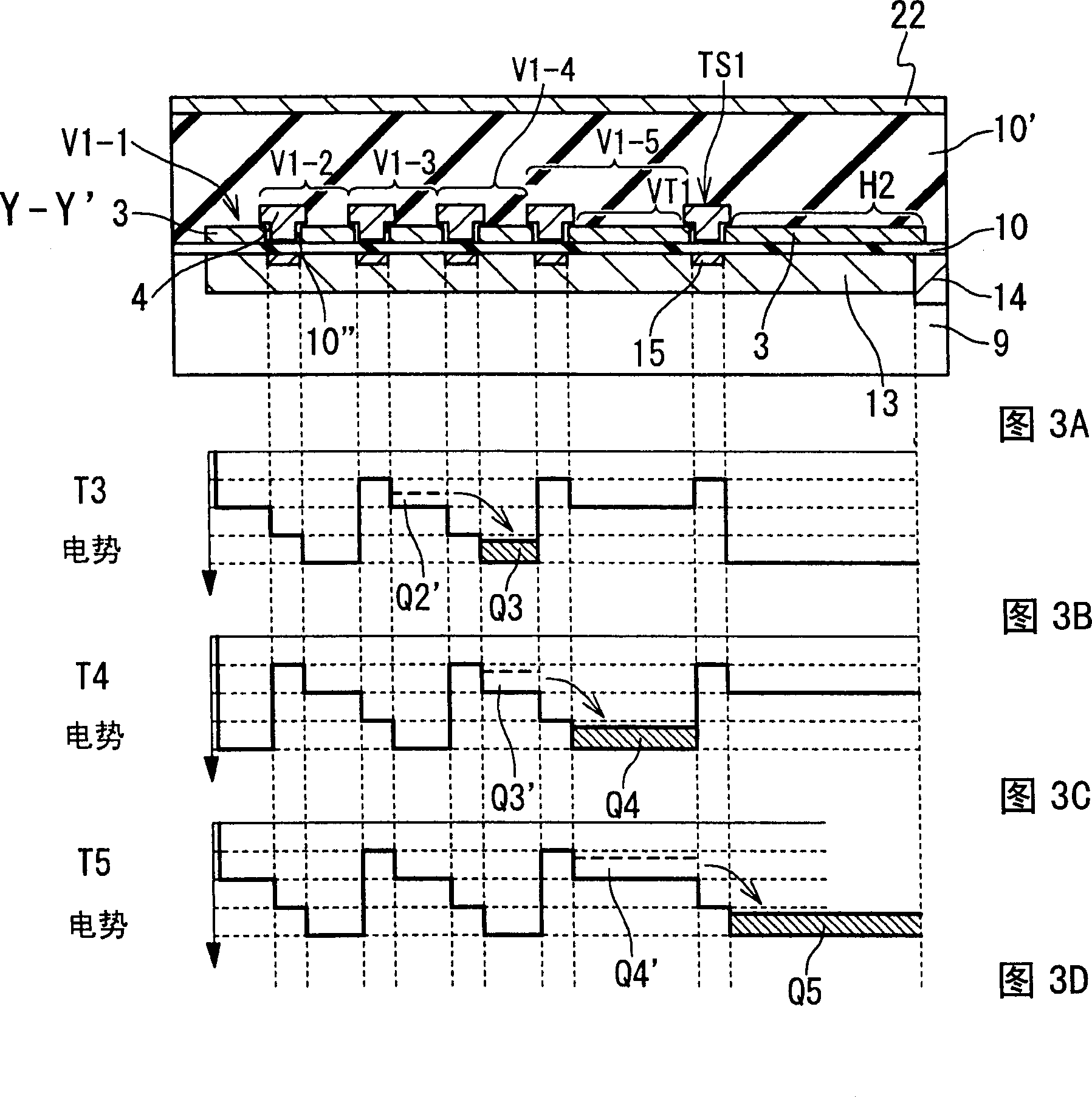

[0056] The following will refer to figure 1 The structure of the color image sensor according to the first embodiment of the present invention will be described. figure 1 A plan view showing the structure of the color image sensor according to the first embodiment of the present invention. The color image sensor includes: pixels P1-1 to P3-4, read gates RE1-1 to RE3-4, vertical scan charge transfer sections V1 to V4, horizontal scan charge transfer sections H, reset gates RS1 to RS4 , reset drains RD1 to RD4, and transfer switch sections TS1 to TS4. The color image sensor in the first embodiment is formed on a P-type substrate. However, the present invention can also be realized by forming a P-type well on an N-type substrate.

[0057] Here, in the description of the drawings of the present application, a wiring structure to each gate electrode, a via hole in a wiring connection portion, and a color filter are omitted. In addition, a metal thin film 22 for light shielding ...

no. 2 example

[0152] The following will refer to Figure 8 A color image sensor according to a second embodiment of the present invention will be described. Figure 8 A plan view showing the structure of a color image sensor according to a second embodiment of the present invention. The color image sensor includes: the first row of pixels P1-1 to P1-4 to the third row of pixels P3-1 to P3-4; the read gate RE1- corresponding to the pixels P1-1 to P3-4 1 to RE3-4; storage gates V1 to V4 as vertical scan charge transfer section H; reset drain RDi and transfer switch TSi. The color image sensor in this embodiment is formed on a P-type substrate.

[0153] The difference between this embodiment and the first embodiment is that the vertical scanning charge transfer sections V1 to V4 having a plurality of vertical scanning charge-coupled units are used in the first embodiment, while a single storage Grid 19. By using a single storage gate, the voltage pulse φ for multiple vertical scanning char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com