Manual tongs

A technology of pliers and pliers legs, which is applied in the field of manual pliers, can solve the problems such as defects in the shape of the space action structure, cannot be realized, etc., and achieves the effect of saving assembly space, low cost, and enhancing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

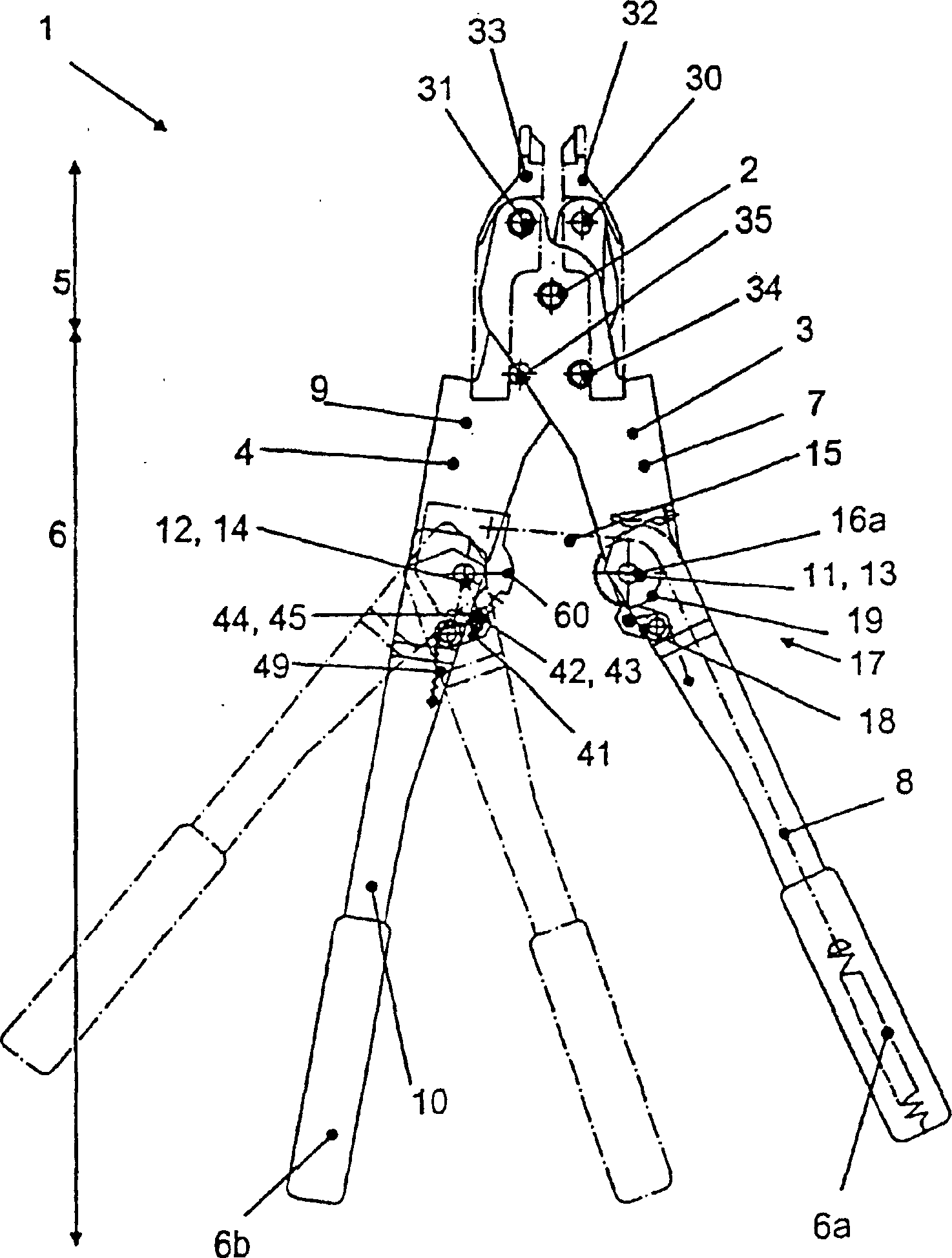

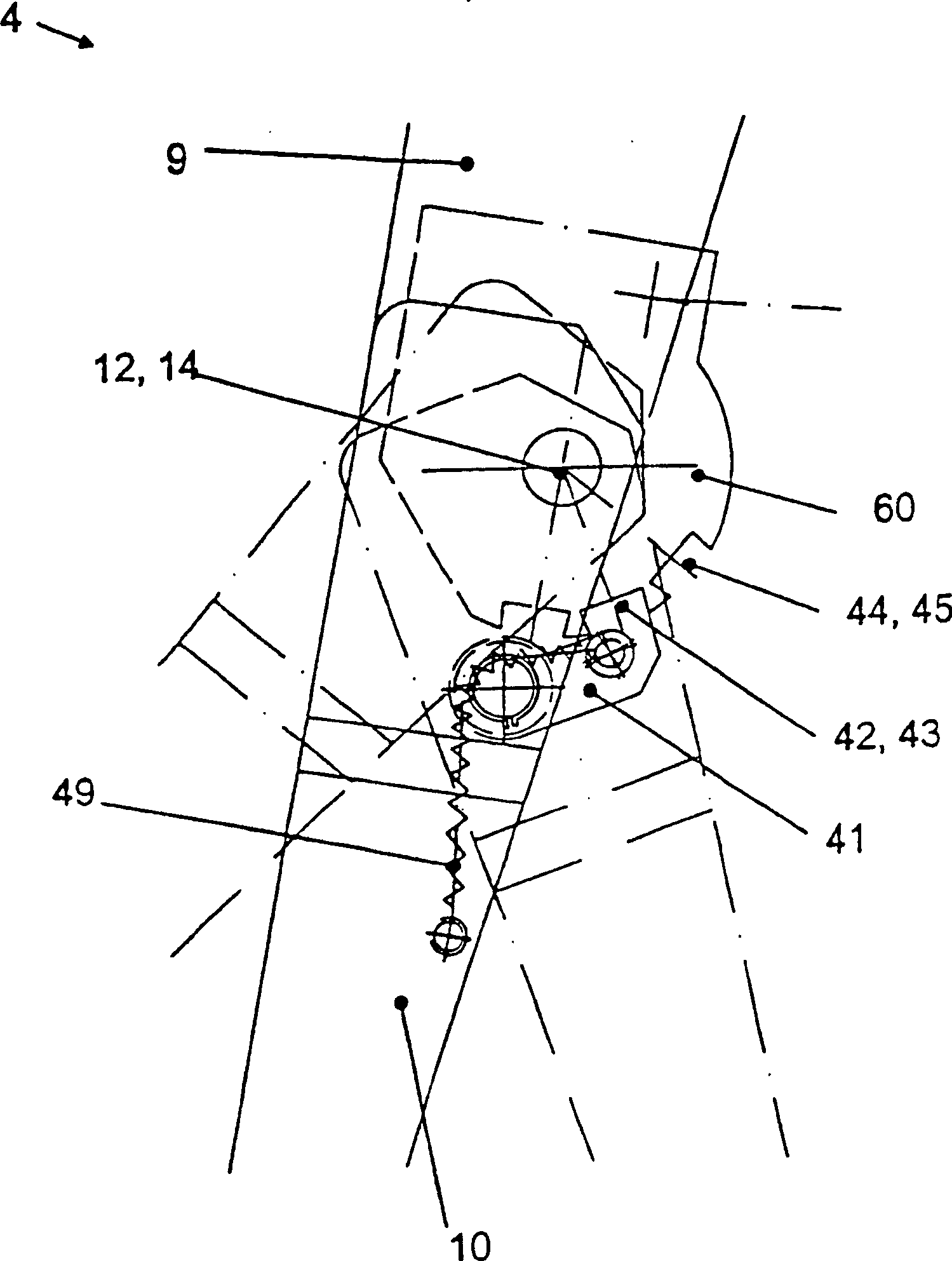

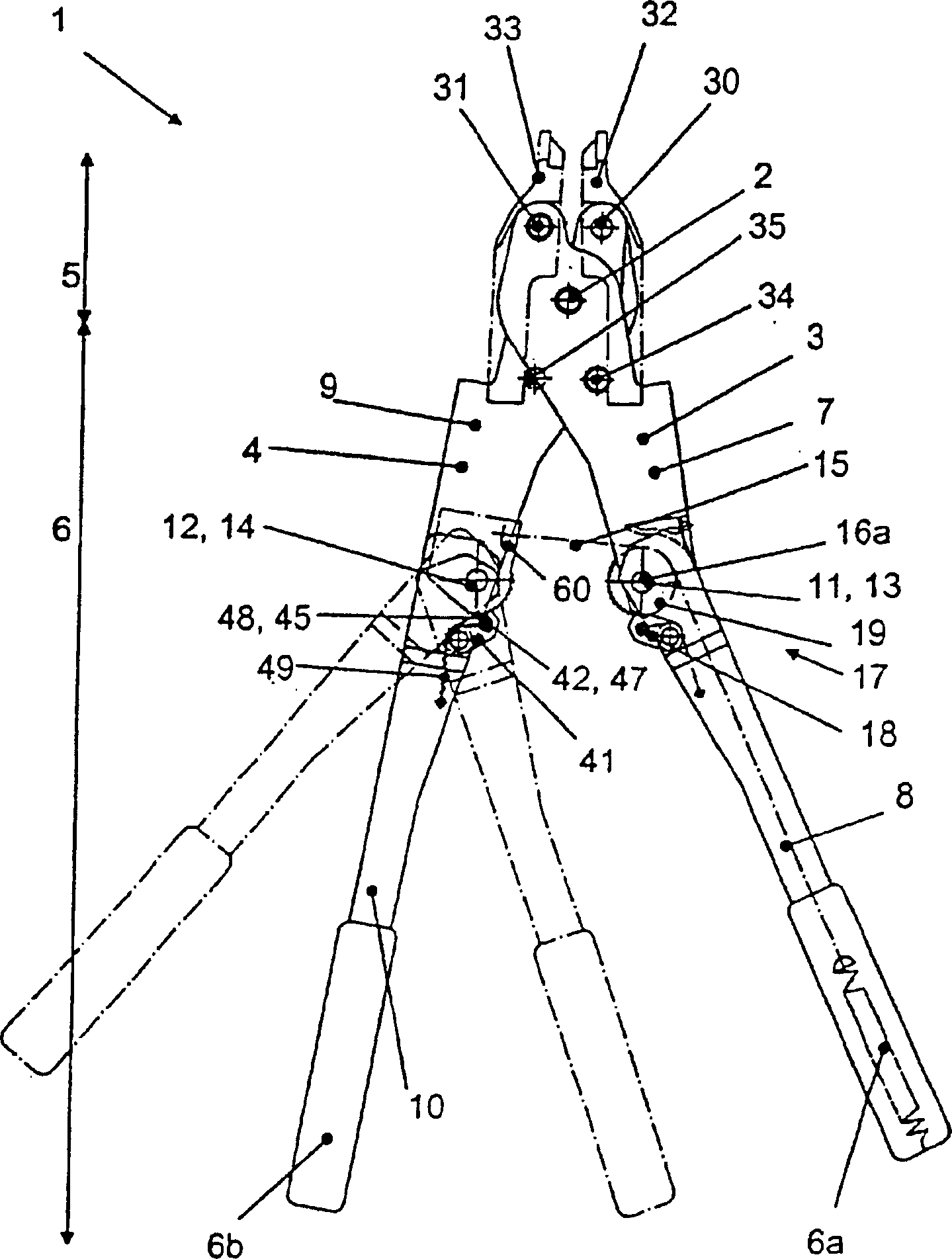

[0023] The manual pliers 1 is indicated as a whole by the reference symbol 1 in all figures. Its main components are two pliers legs 3 , 4 rotatably connected to each other on a first rotational axis 2 . The pliers legs 3 , 4 are divided into a tool section 5 on the side of the first axis of rotation 2 and a lever section 6 on the side of the first axis of rotation 2 . The handles 6 a , 6 b are each located at the end of the lever segment 6 . Like the second pliers leg 4 , the first pliers leg 3 is likewise divided into a lever 7 , 9 remote from the handle and a lever 8 , 10 close to the handle. The levers 7, 9 far away from the handle and the levers 8, 10 close to the handle are rotatable on the second 13 or the third 14 rotating shafts 13, 14 through the first 11 or the second 12 hinge joints 11, 12 respectively. interconnected.

[0024] In three different exemplary embodiments of the manual pliers 1 according to the invention, a tensioning mechanism 15 extends between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com