Laminated dielectric filter

A filter and dielectric technology, applied in the field of laminated dielectric filters, can solve problems such as unfavorable filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

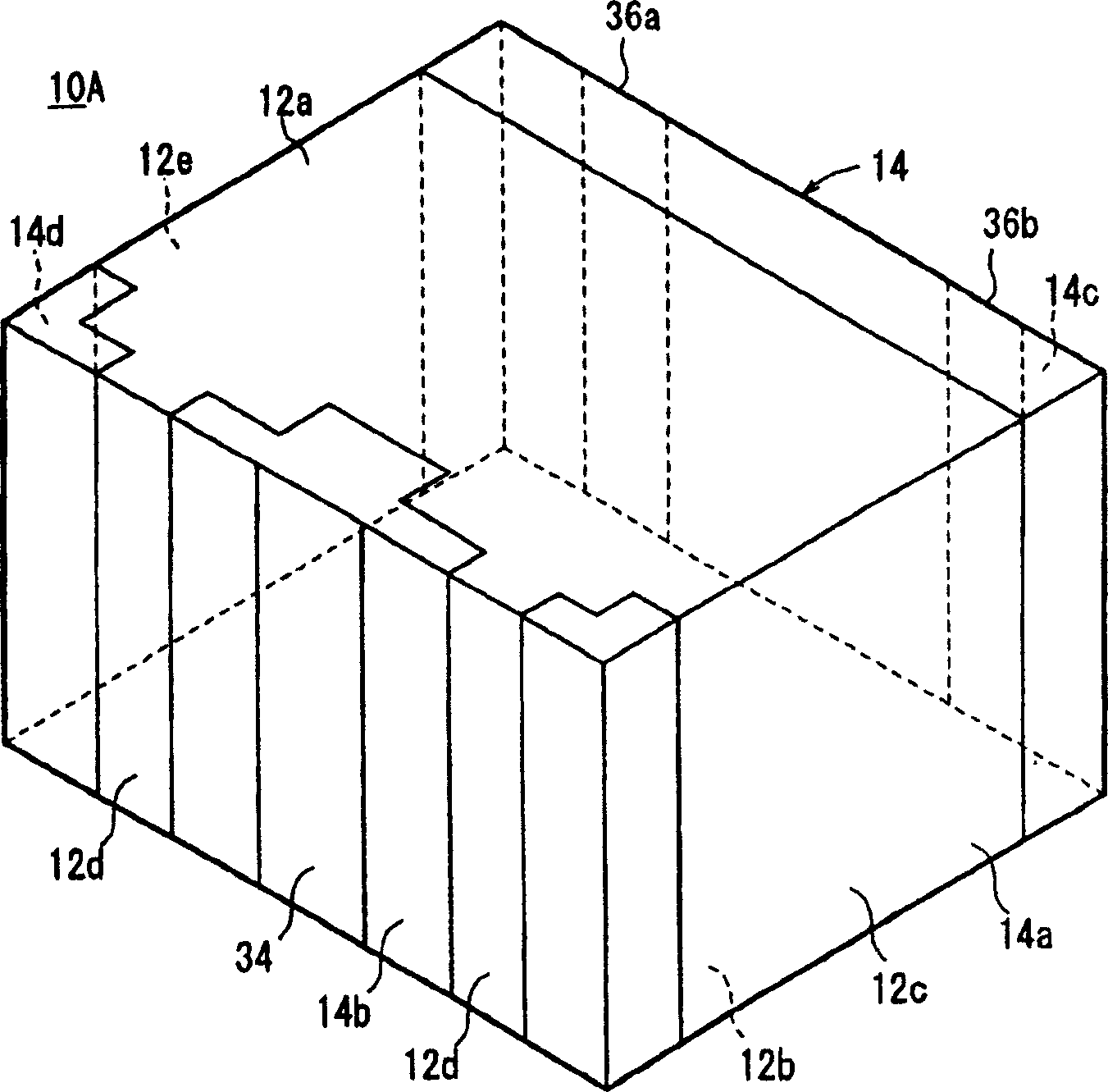

[0082] Refer below Figure 1-29 Several illustrative embodiments of a laminated type dielectric filter according to the present invention are explained. In the following embodiments, the case where the input terminal is unbalanced and the output terminal is balanced is roughly explained. The present invention is also applicable to the case opposite to the above.

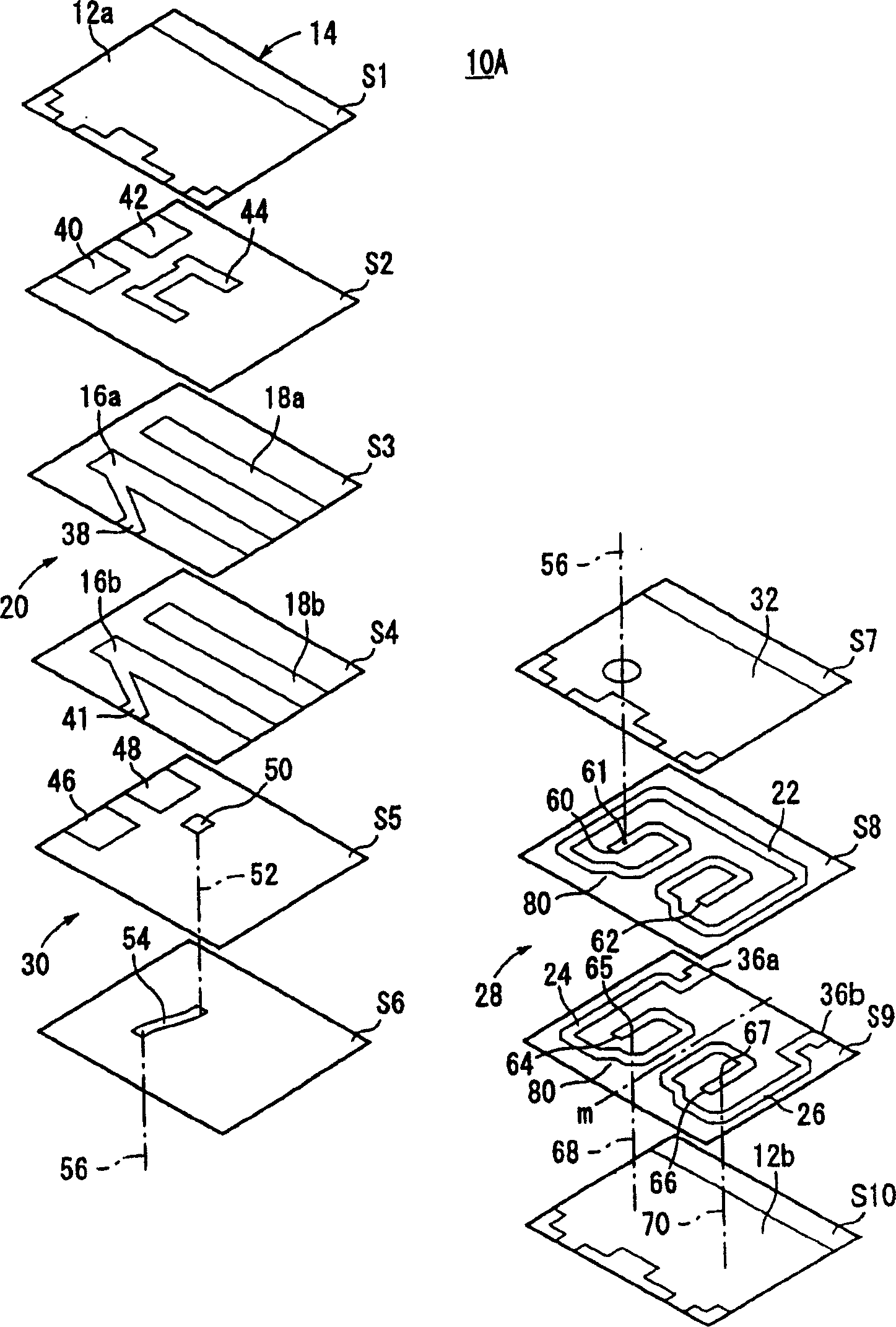

[0083] like figure 1 As shown, the laminated dielectric filter 10A of the first embodiment has a dielectric substrate 14 . The dielectric substrate 14 includes a plurality of dielectric layers (S1-S10, see figure 2 ). Ground electrodes 12a, 12b are formed on both main surfaces of the dielectric substrate 14 (the first main surface of the first dielectric layer S1 and the first main surface of the tenth dielectric layer S10).

[0084] like figure 2 As shown, a filter element 20 , an unbalanced-balanced conversion element (transition element 28 ), and a connection element 30 are disposed within the dielectric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com