Compact fluorescent lamp with shell structure

A fluorescent lamp, compact technology, applied in the direction of gas discharge lamps, the use of gas discharge lamps, parts of gas discharge lamps, etc., can solve the problem that fluorescent lamps cannot cover the temperature range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

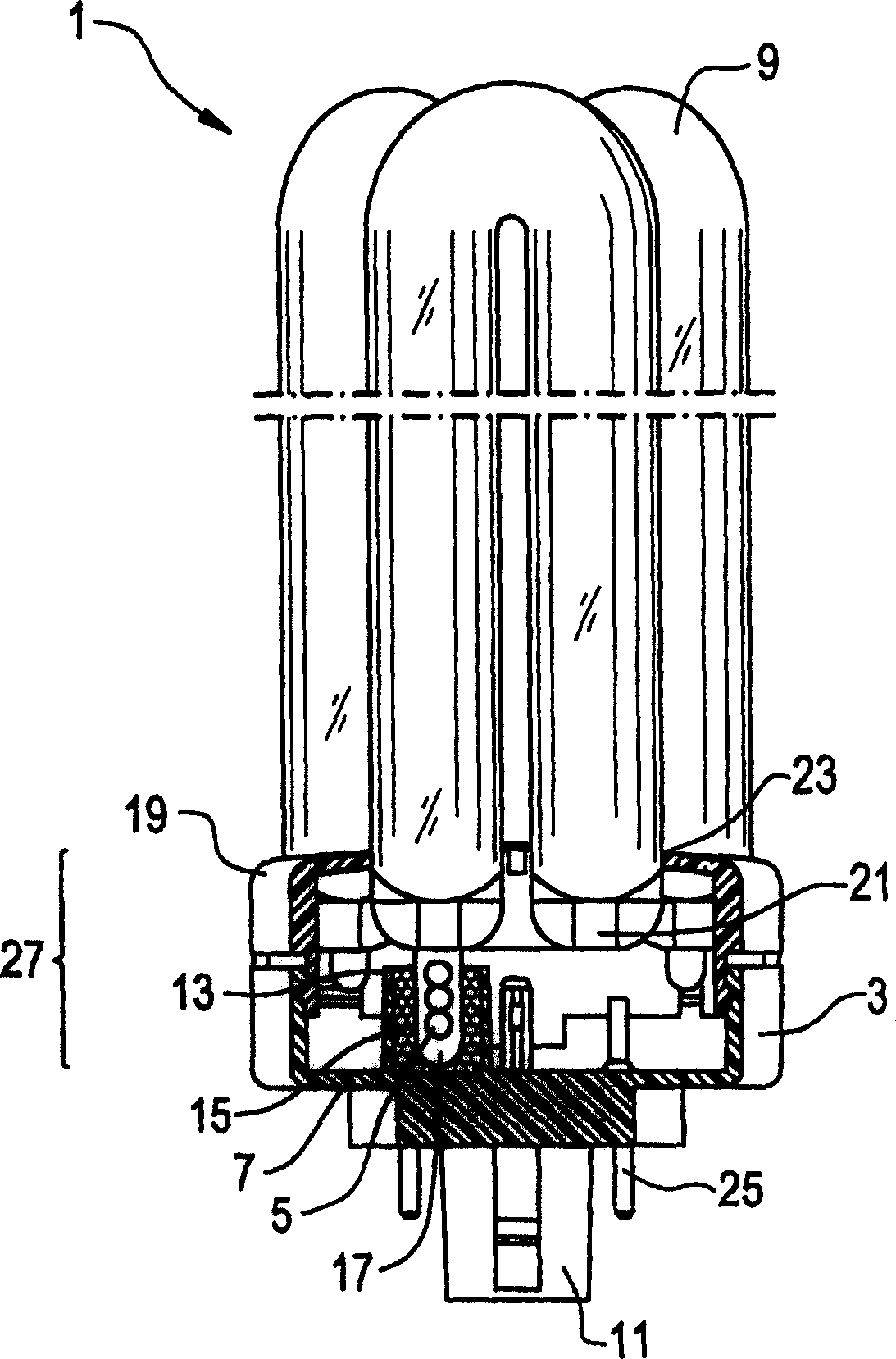

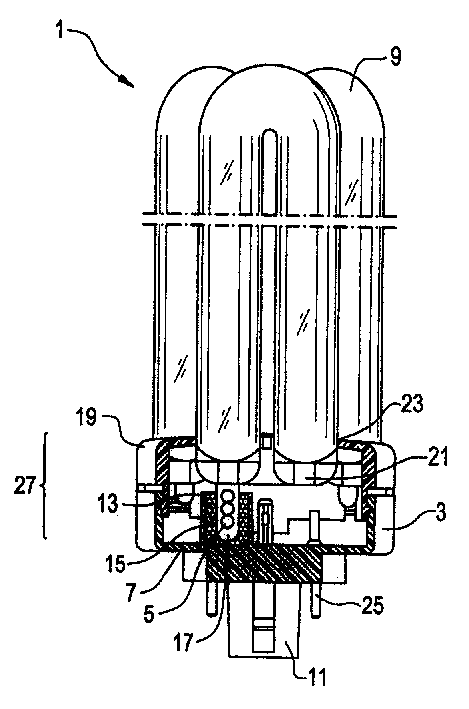

[0011] figure 1 A compact fluorescent lamp 1 with a discharge vessel 9 and a housing 27 is shown. The case 27 includes the case 3 and the cover 19 . The housing 3 and the cover 19 are fixed to each other on their periphery. The discharge vessel 9 comprises three U-shaped tubes whose ends 21 bridge each other so that a continuous path of the discharge arc is formed. The discharge vessel 9 is filled with inert gas and mercury, and the U-shaped tube is sealed at the end 21 . The end 21 of the U-shaped tube extends into the interior of the housing 27 through an opening 23 in the upper part of the cover 19 of the housing 27 and is firmly fixed therein. One end of the U-shaped tube is equipped with a pin 17 communicating with the discharge tube 9 . The amalgam ball 5 is housed in the pin 17 and extends down to the bottom of the housing 3 . The amalgam ball 5 is placed at the lower end of the pin 17.

[0012] A heat conducting member is provided around the pin 17, which is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com