Compound insulator with core rod structure

A composite insulator and inner core technology, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of low transverse insulation strength, hydrolysis damage, fracture damage, etc., to improve the extremely uneven electric field, prevent brittle faults, increase mechanical The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

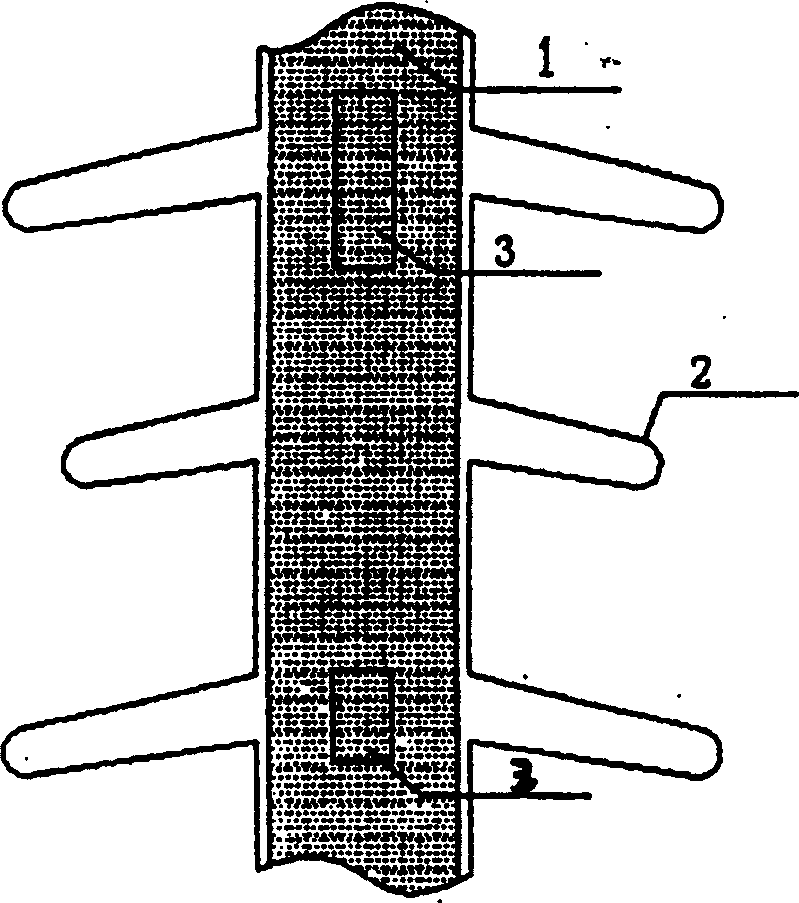

[0025] The invention is composed of a mandrel 1, an umbrella skirt 2 outside the mandrel and metal ends at both ends of the mandrel. An inner mandrel is embedded in the mandrel, and the glass fiber impregnated with the epoxy resin matrix is arranged in parallel along the longitudinal direction of the mandrel, or partly wrapped or woven at a certain angle with the longitudinal direction as required. The inner mandrels are embedded in different positions in the mandrel, and the number of the inner mandrels is less than or equal to the number of the outer sheds. The shape of the inner mandrel is cylindrical or other appropriate shapes, and the length is 1mm-1000mm. The inner mandrel is made of high tensile strength steel or other suitable metallic material. In the same composite insulator, the shape of the inner core rods can be equal or unequal, the diameter of the inner core rods can be equal or unequal, and the distance between the inner core rods can be equal or unequal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com