Electric heating dual-pipe type contact type singeing frame

A double-tube, contact-type technology, applied in singeing, textile and papermaking, fabric surface trimming, etc., can solve the problems of easy deformation of the cylinder, uneven heating, high energy consumption, etc., and achieve uniform surface quality and energy saving Remarkable effect and uniform wall surface temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

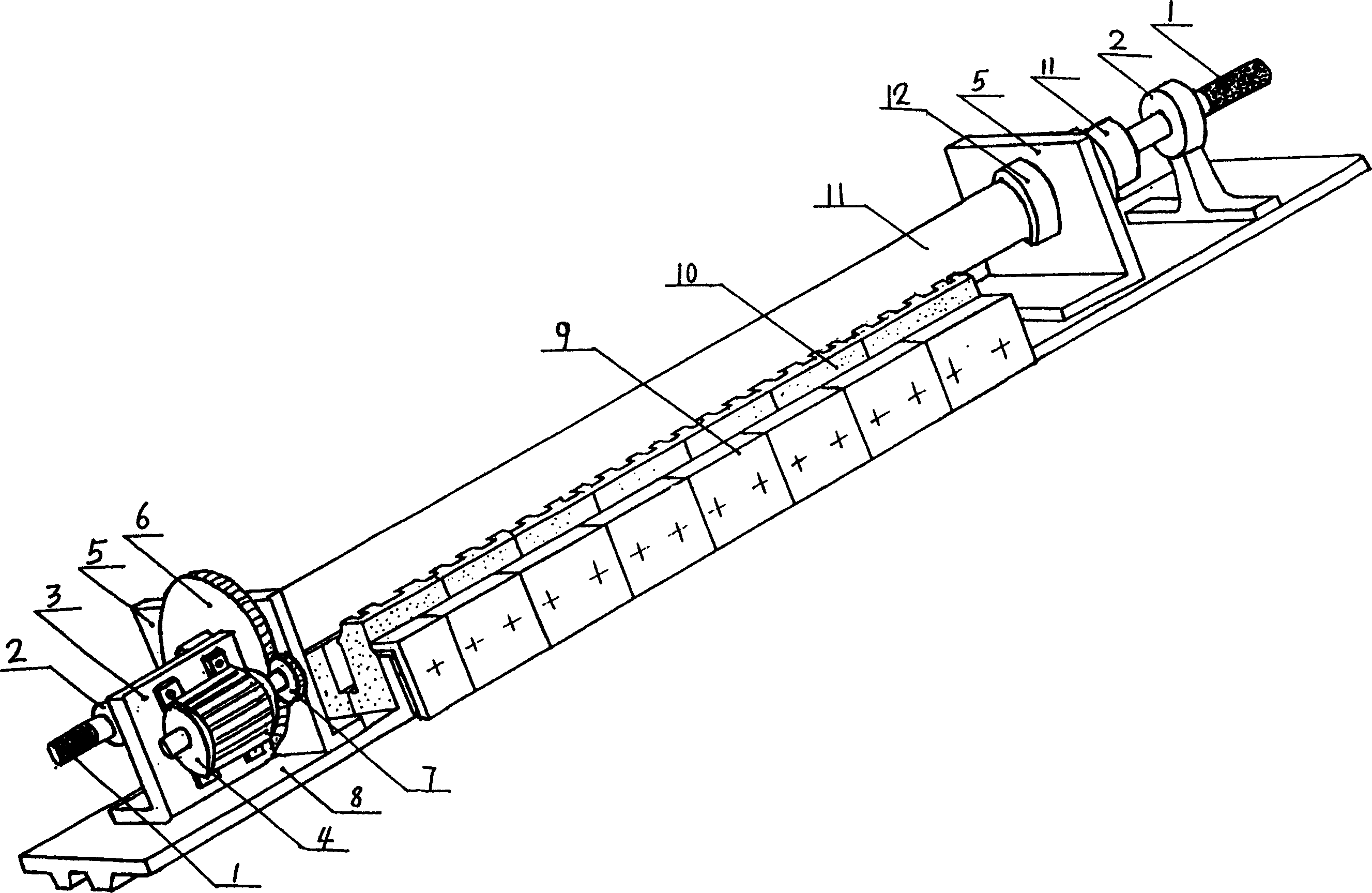

[0013] Accompanying drawing has provided the structural representation of the present invention. Wherein it mainly contains a heating body 1, a heat carrying pipe 11, a motor 4, a support 5, a bent plate 3 and a burner body 8. The heating element 1 is placed in the heat-carrying tube 11 (the two are not in contact) and the two ends extend out of the heat-carrying tube 11, and one end is installed on the tile frame 2 fixed on the burner body 8 (the insulating material is housed in the tile frame 2 mounting hole). ), one end is fixed on the bent plate 3 (the mounting hole on its back plays the role of tile frame), and the two ends are connected to the power cord. The heating element can be a functional ceramic tube or a silicon carbide electric heating element sprayed with metal powder at both ends, or a heat-resistant non-metallic rod wound with a resistance wire. Functional ceramics refer to conductive ceramics, which can conduct electricity and generate heat after being spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com