Spring spindle

A technology of spindles and compression springs, which is applied in the field of spring spindles, can solve the problems that the weaving products cannot be guaranteed to be uniform in density, the surface is smooth and smooth, the distance between the knitting machine table tops is limited, and the normal work is affected, so as to achieve light weight, improve the working environment, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

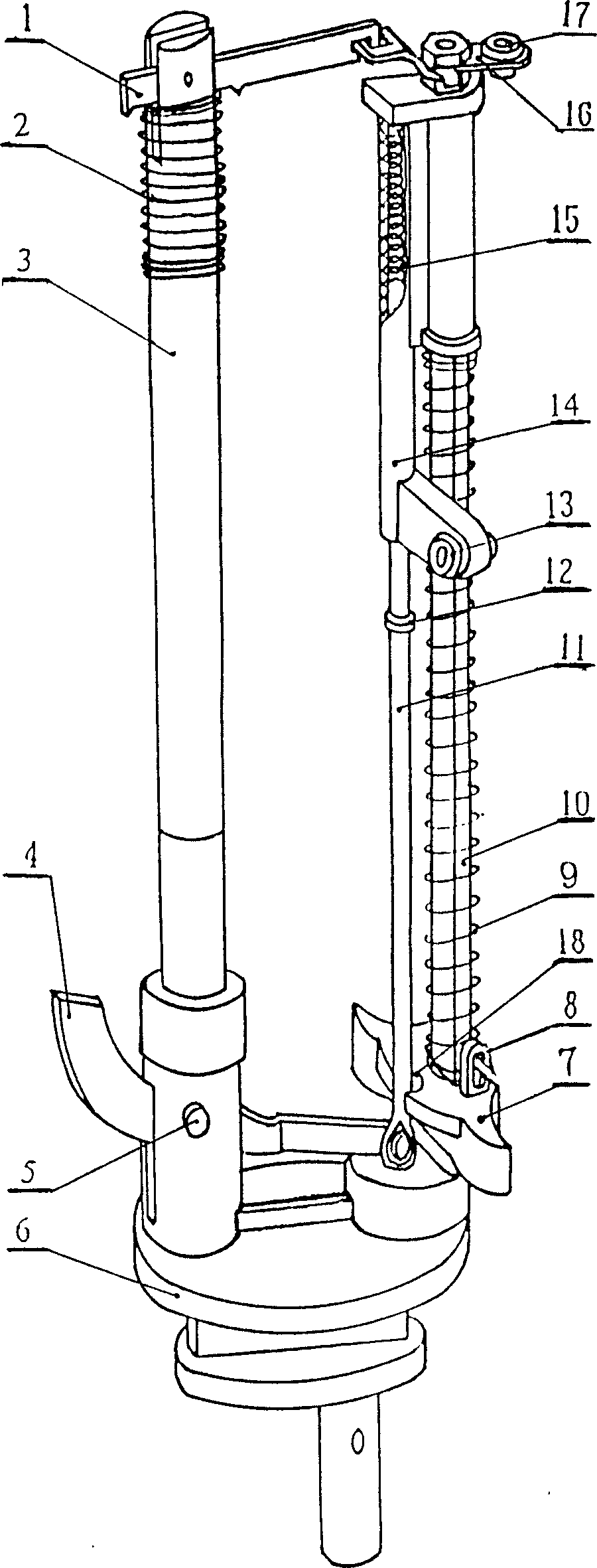

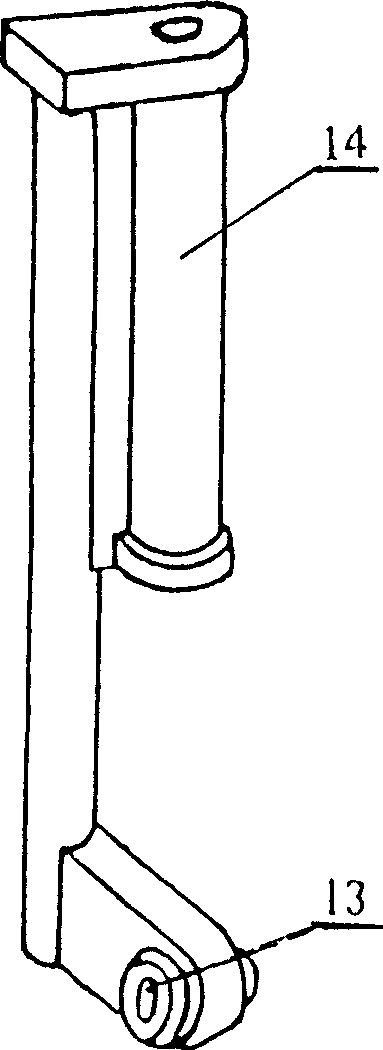

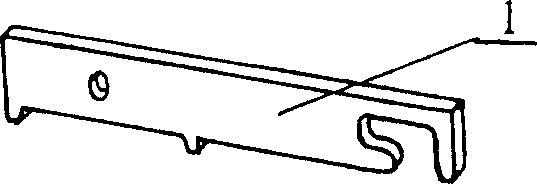

[0017] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0018] Left and right columns 3,10 are die-cast in the through hole at the top of the runway bar 6, and are fixed into one body to form a fixture.

[0019] The left column 3 is cylindrical, with an open slot in the middle of the top, and two corresponding through holes communicated with the middle open slot on the front and rear walls.

[0020] Right column 10 sections are waist-shaped, and the top is screw rod.

[0021] The track bar 6 is the same as the prior art, and is injection-molded by composite material, wear-resistant and low-noise.

[0022] Slide block 7 is made by metal material, is the gold ingot shape that waist-shaped through hole is arranged in the middle, has a circular arc-shaped gap 18 at the inner side upper end, the middle edge place, and a screw hole is arranged on the upper surface.

[0023] Wire hook 8 is made by high wear-resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com