Mechanism for automatically tearing off double faced adhesive tape release paper

A technology of double-sided adhesive and release paper, applied in paper/cardboard containers, container manufacturing machinery, containers, etc., can solve problems such as high cost and impact on product quality, and achieve the effects of convenient operation, simple structure, and increased success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

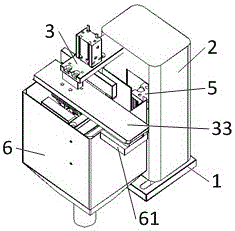

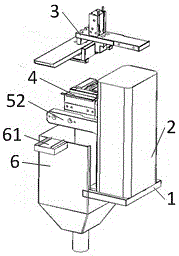

[0017] Such as Figure 1~5 As shown, the present invention includes a base 1, a protective cover 2, a pressing device 3, a paper clamping device 4 and a lifting device 5, the base 1 is provided with a protective cover 2, and waste paper is installed on one side of the protective cover 2 The collection box 6 is connected with the base 1 at the bottom of the waste paper collection box 6 .

[0018] The lifting device 5 is installed on the base 1, the lifting device 5 is made up of a transmission part 51 and a non-transmission part 52, the transmission part 51 is located in the protective cover 2, the non-transmission part 52 of the lifting device 5 stretches out from the protective cover 2 and Located in the waste paper collection box 6.

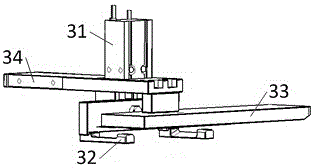

[0019] The paper clamping device includes a clamping knife 41, a clamping fixed block 42, a clamping knife pre-pressing block 43, a spring 44 and a clamping cylinder 45, wherein the cylinder body of the clamping cylinder 45 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com