Hygenic cigarette packing-shaping device

A molding device and hygienic technology, applied in the field of machinery, can solve the problems of smokers' health hazards and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

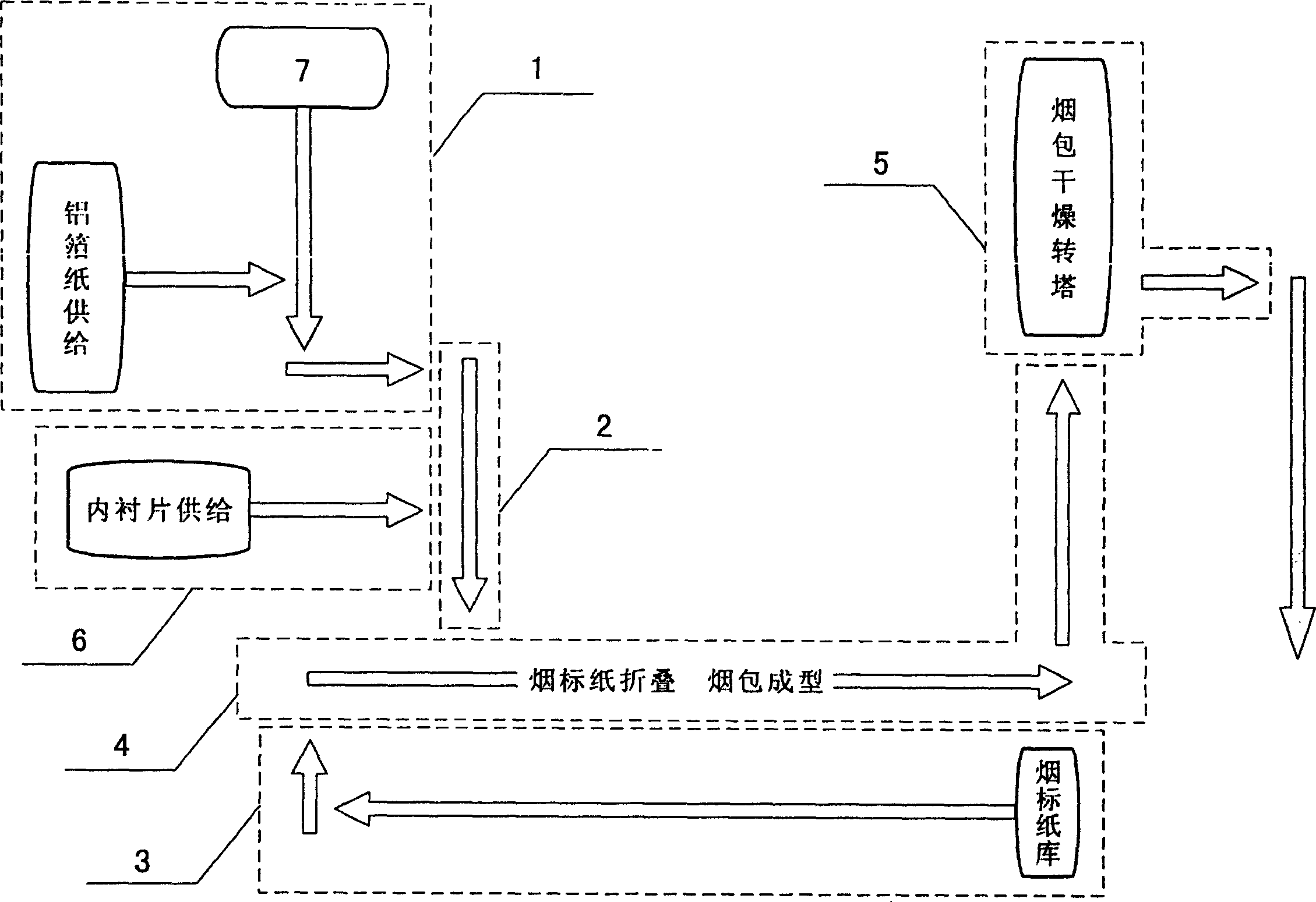

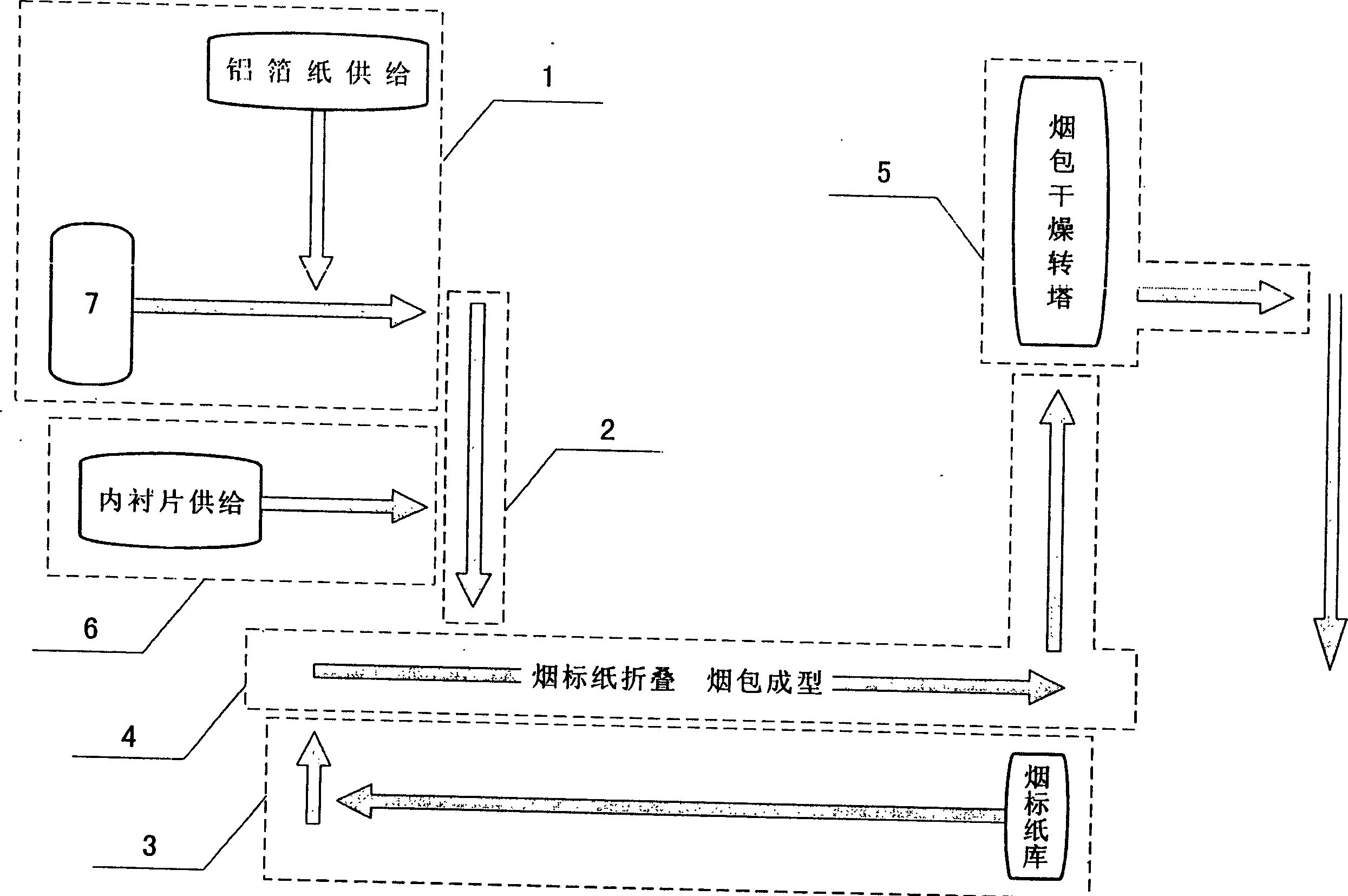

[0071] Transformation of YB41 and YB43 cigarette packaging machines.

[0072] 1. Transformation of the first part 1 of YB41 and YB43 cigarette packaging machines:

[0073] 1) Modification of the base of the first part 1

[0074] Since the first part 1 of the device of the present invention (the cigarette storehouse 7 to the aluminum foil paper 10 is folded) is rotated 90° counterclockwise relative to the second part 2 as a whole, the base of the first part 1 will also be rotated 90° counterclockwise accordingly. °. And because the base of the first part 1 and the base of the second part 2 are an integral body in the original YB41 and YB43 machines, it can be considered to divide the original base into two when transforming the base of the first part 1, or redesign, Machining a base to pair with the first part 1 . The connection and fixing structure of the base of the first part 1 and the base of the second part 2 can be designed according to the actual situation.

[0075] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com