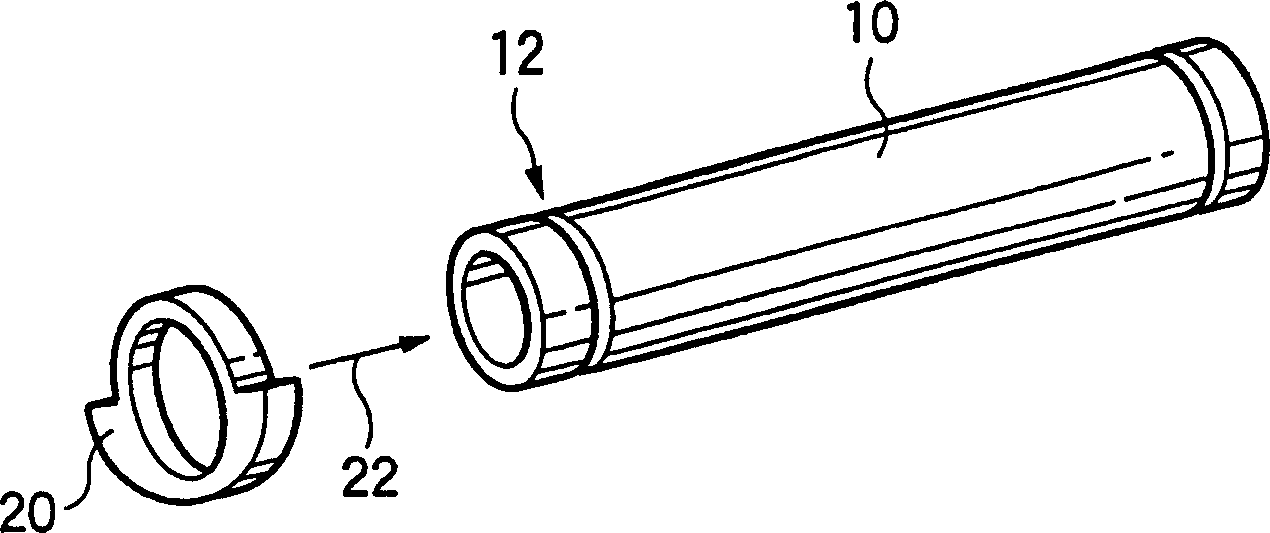

Heated rotary drum and image forming device using said heated rotary drum

A technology for heating rollers and images, which is applied to the electric recording process using charge patterns, the equipment, shafts and bearings of the electric recording process applying charge patterns, etc. performance, reduced wear, improved deflection and sag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

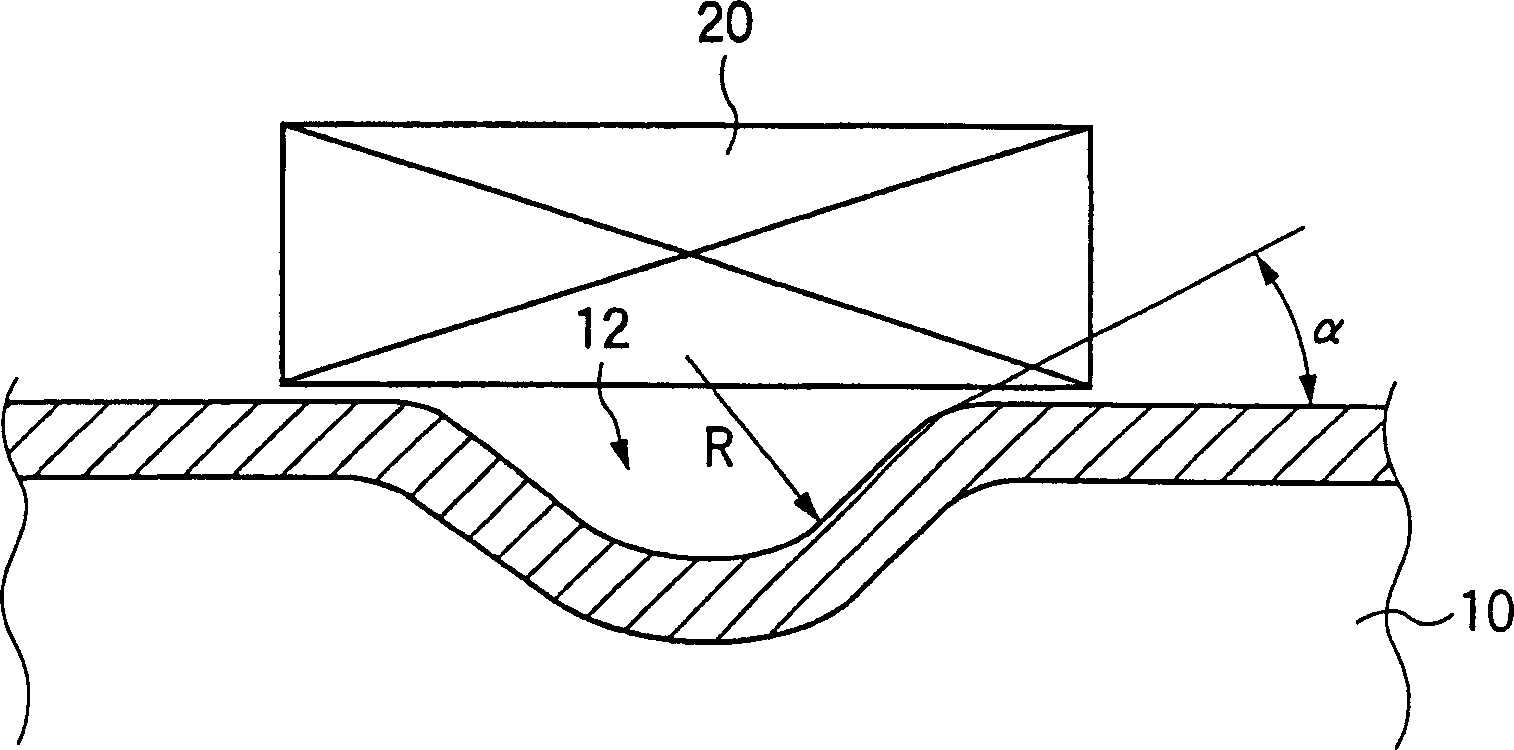

Method used

Image

Examples

Embodiment Construction

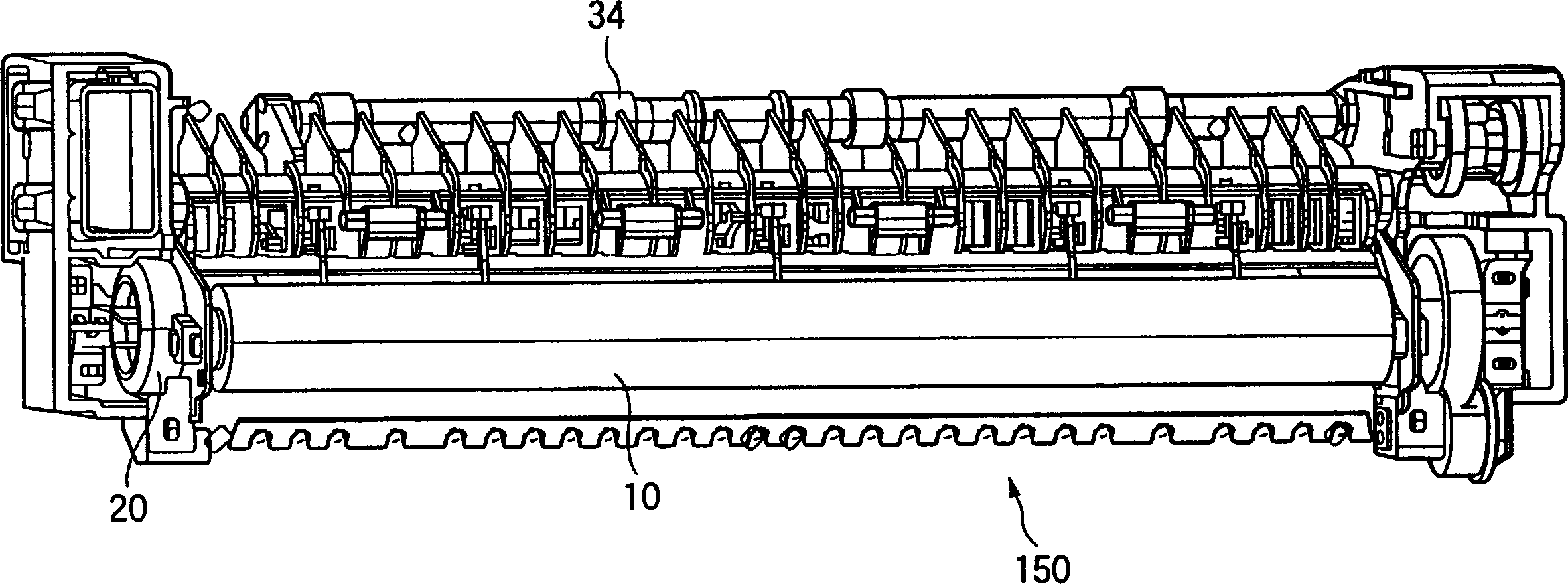

[0013] Embodiments of the present invention will be described below.

[0014] Figure 5 It is an overall explanatory diagram showing the image forming apparatus 100 to which the present invention is applied. Image forming apparatus 100 supplies static electricity from electrostatic roller 104 to photosensitive drum 102 to charge the photosensitive drum, and forms a latent image on photosensitive drum 102 by irradiating light such as laser light from exposure light unit 106 . The powder is supplied from the developing roller 110 of the developing device 18 to develop an image on the photosensitive drum 102 . The paper supplied through the paper supply path 128 passes between the photosensitive drum 102 and the transfer roller 112 to transfer an image onto the paper, and then the fixing roller 114 fixes the image on the paper. Paper is drawn from the paper cassette 120 through a paper supply path and advances over supply rollers 122,124. After being positioned on the registra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com