Waste gas treatment equipment for air film-biological reactor

A technology of waste gas treatment equipment and bioreactor, which is applied in the direction of air quality improvement, chemical instruments and methods, separation methods, etc., can solve the problems of substandard exhaust gas, prolonged residence time, high operating costs, etc., and achieve stable output gas concentration, The effect of reducing the number of auxiliary equipment and the number of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

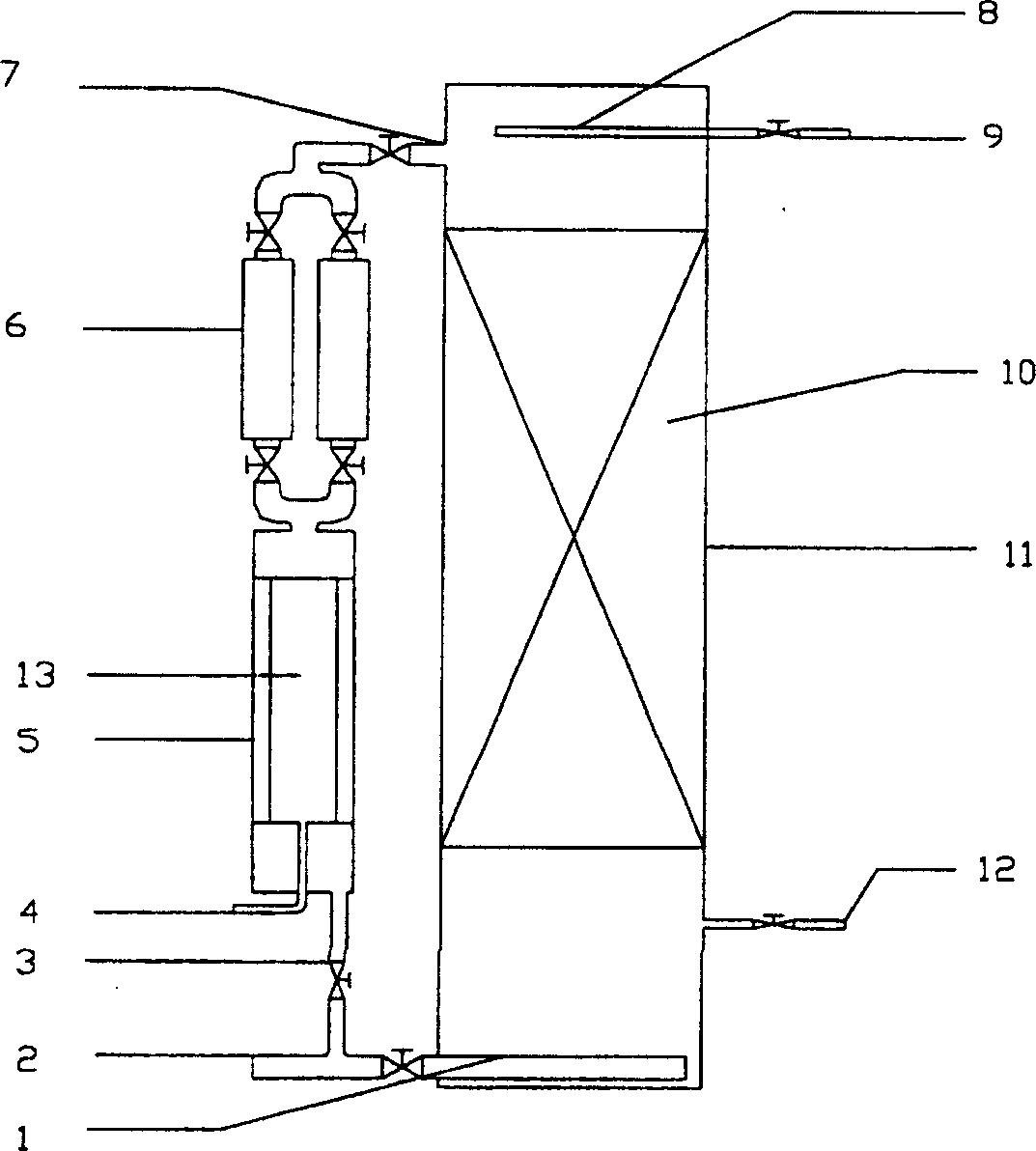

[0032] See figure 1 .

[0033] Air film-bioreactor exhaust gas treatment equipment made of plastic plates, its length, width and height are 30cm, 15cm, 1200cm respectively, including bioreactor 11 with packing, gas separator 5, etc.; Bioreactor 11, equipped with air membrane module 13 (membrane area is 0.2-0.3m 2 ) gas separator 5 and a desiccant drier 6 constitute;

[0034] An air inlet 2 is opened on the lower side wall of the bioreactor 11, and a perforated pipe 1 is installed at the air inlet 2. The other side wall of the lower part is provided with a water outlet 12, the air inlet 2 should be lower than the water outlet 12, and the upper side wall is provided with a spray liquid inlet 9, and there is another perforated pipe 8 at the inlet 9;

[0035] The inside of the bioreactor 11 is filled with fillers 10 such as sponge or perlite, and the other side wall of the upper part is provided with an air outlet pipe 7, and the air outlet pipe 7 is connected to the dryer 6; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com