Soybean processing

A technique for soybeans and soybean germs, applied in the field of producing soybean germ concentrates, capable of solving problems such as undescribing combinations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

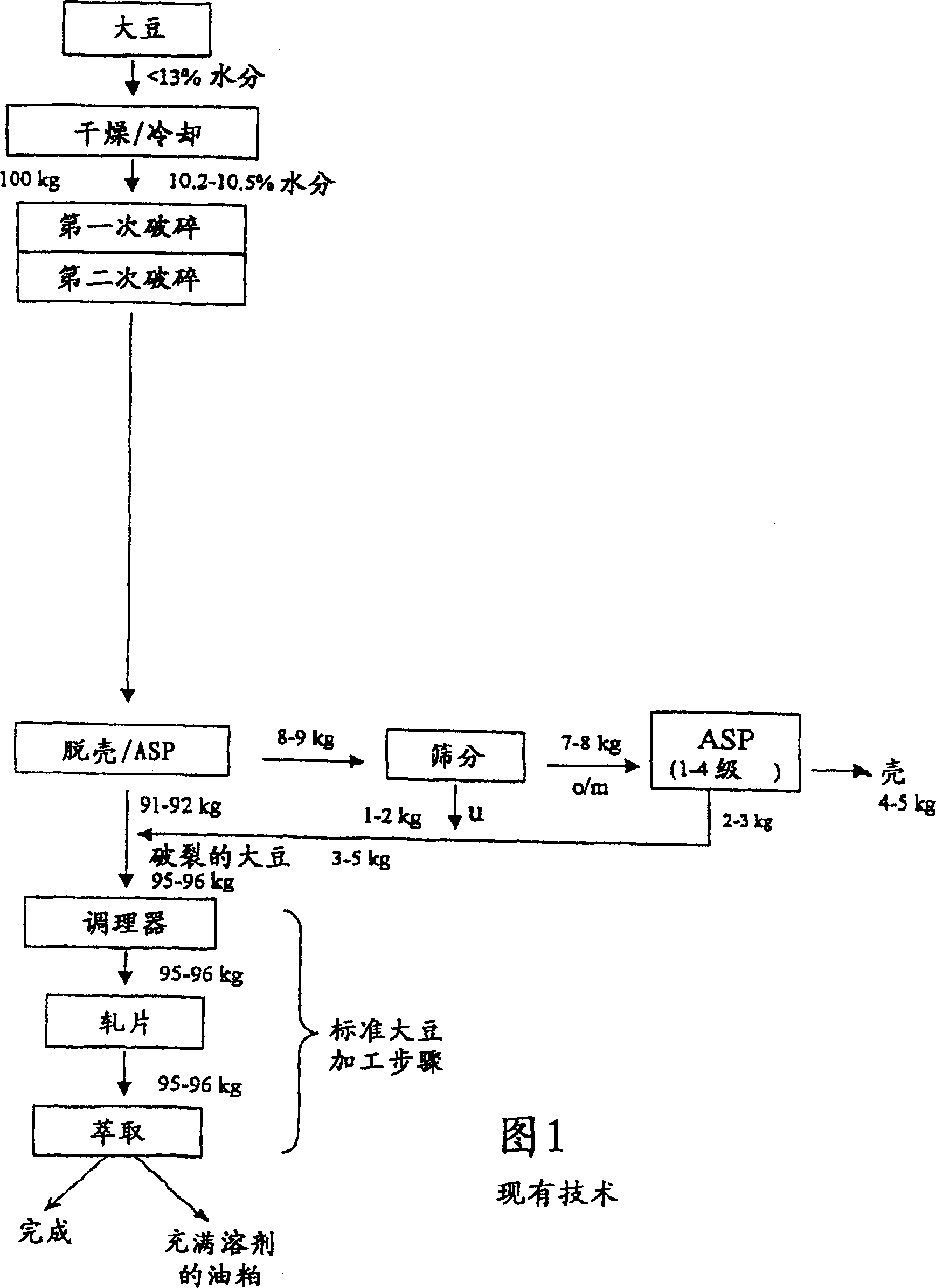

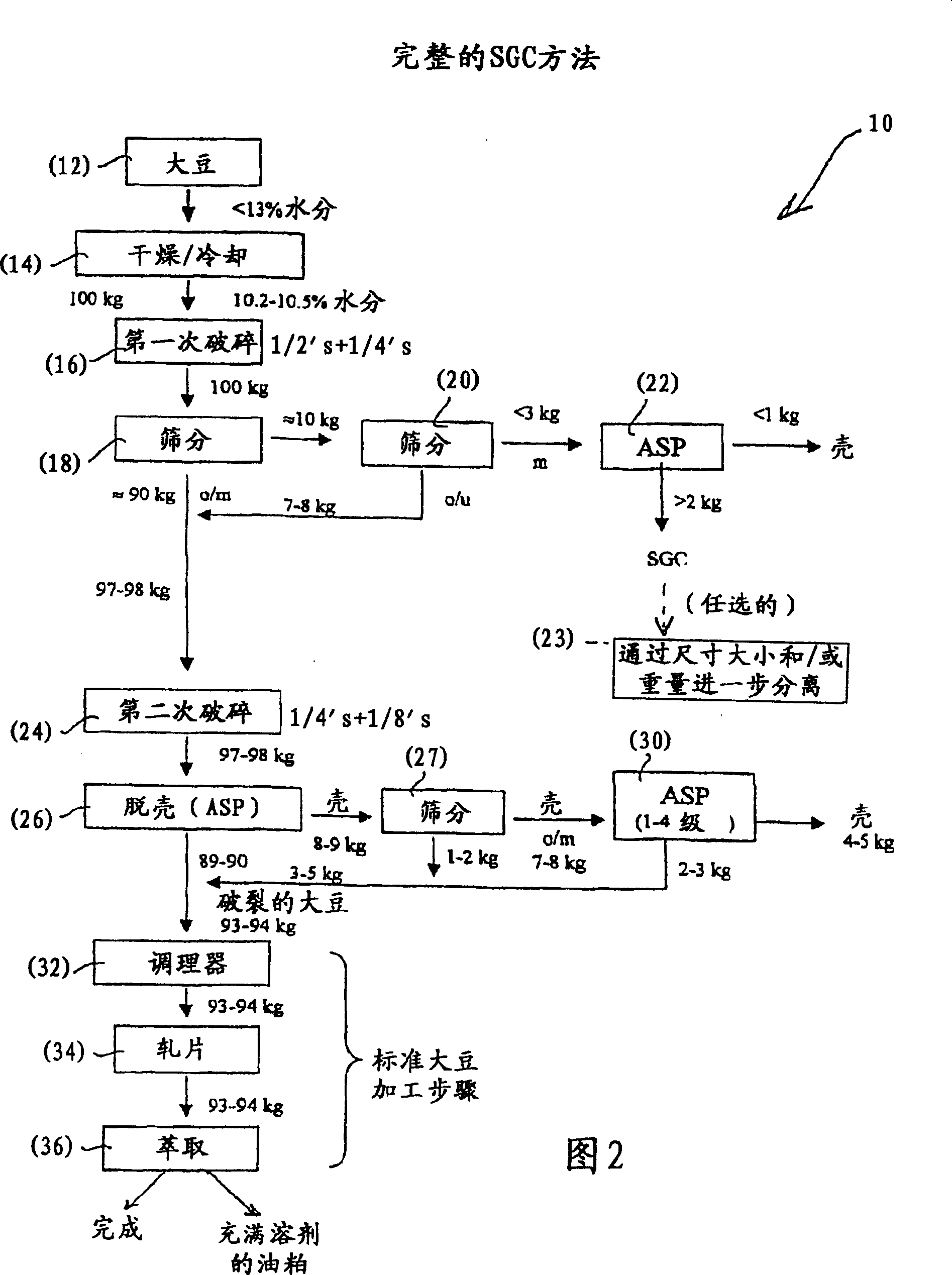

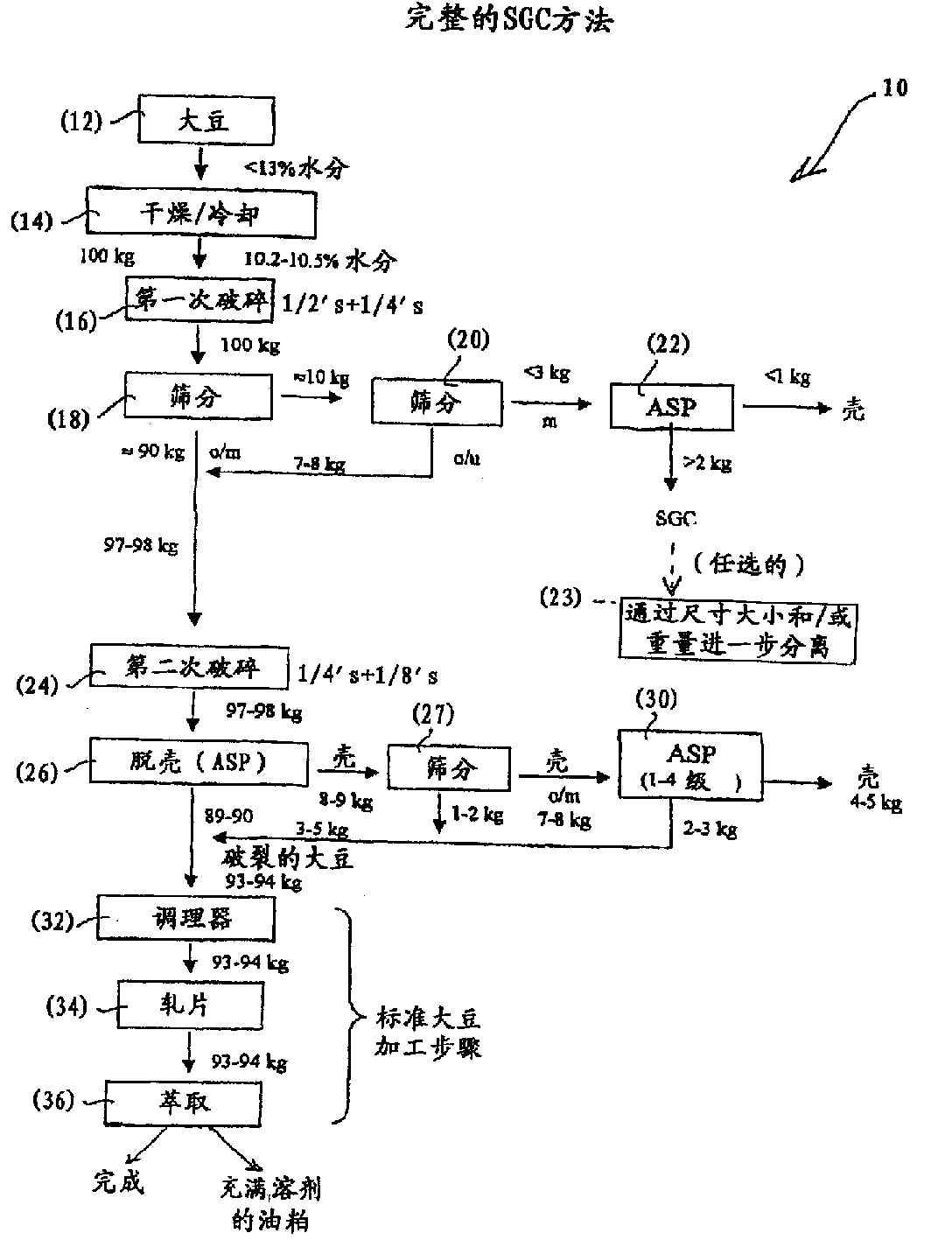

[0055] In a representative day of production, one embodiment of the invention proceeds as follows:

[0056] 1) Use the process shown in Figure 2 and above to form a soybean germ concentrate.

[0057]2) After blending, the moisture content of soybeans is 9.8%.

[0058] 3) The sieve sizes used are those described above.

[0059] 4) The suction pressure used to remove the hulls from the soybean germ concentrate is 0.8 inches of water pressure.

[0060] 5) The particle size distribution after the first crushing step (20) is as follows. Samples were withdrawn approximately every 30 minutes over four hours.

[0061] The following US sieves were used and the data reported are expressed as wt% retained on the sieve. Use the following method. (AACC 55-30 and AOCS Da 28(97))

[0062] #4 4.75mm; #5 4.00mm; #6 3.35mm; #7 2.80mm;

[0063] Sieve number

sample

#4

#5

#6

#7

#8

#10

#12

plate (pan)

#1

20.5

30.0

...

Embodiment 2

[0071] During a representative two-day production cycle, samples of soybean oil and soybean meal were taken under the following two conditions: (a) On the first day, the soybean germ separation equipment was turned off so that the soybean germ was not separated from the feed stream and (b) On the second day, the soybean germ separation equipment was opened and the soybean germ was separated from the feed stream as described above in Example 1. Four samples of all crude soybean oil and soybean meal were taken under each condition.

[0072] Samples were taken at approximately 20 minute intervals. Soybean oil samples were tested for total sterol content (% sterols) (see AOCS Ca 60-40, AOCS Ce 3-74 and AOCS Ch 6-91). Soy flour samples were tested for total isoflavone content (% isoflavones) (see Murphy, Patricia A. et al., Isoflavones in Retail and Industrial Soy Foods, J. Agric. Food Chem., Vol. 47, pp. 2697-2704 ). The isoflavone content is expressed as a range because the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com