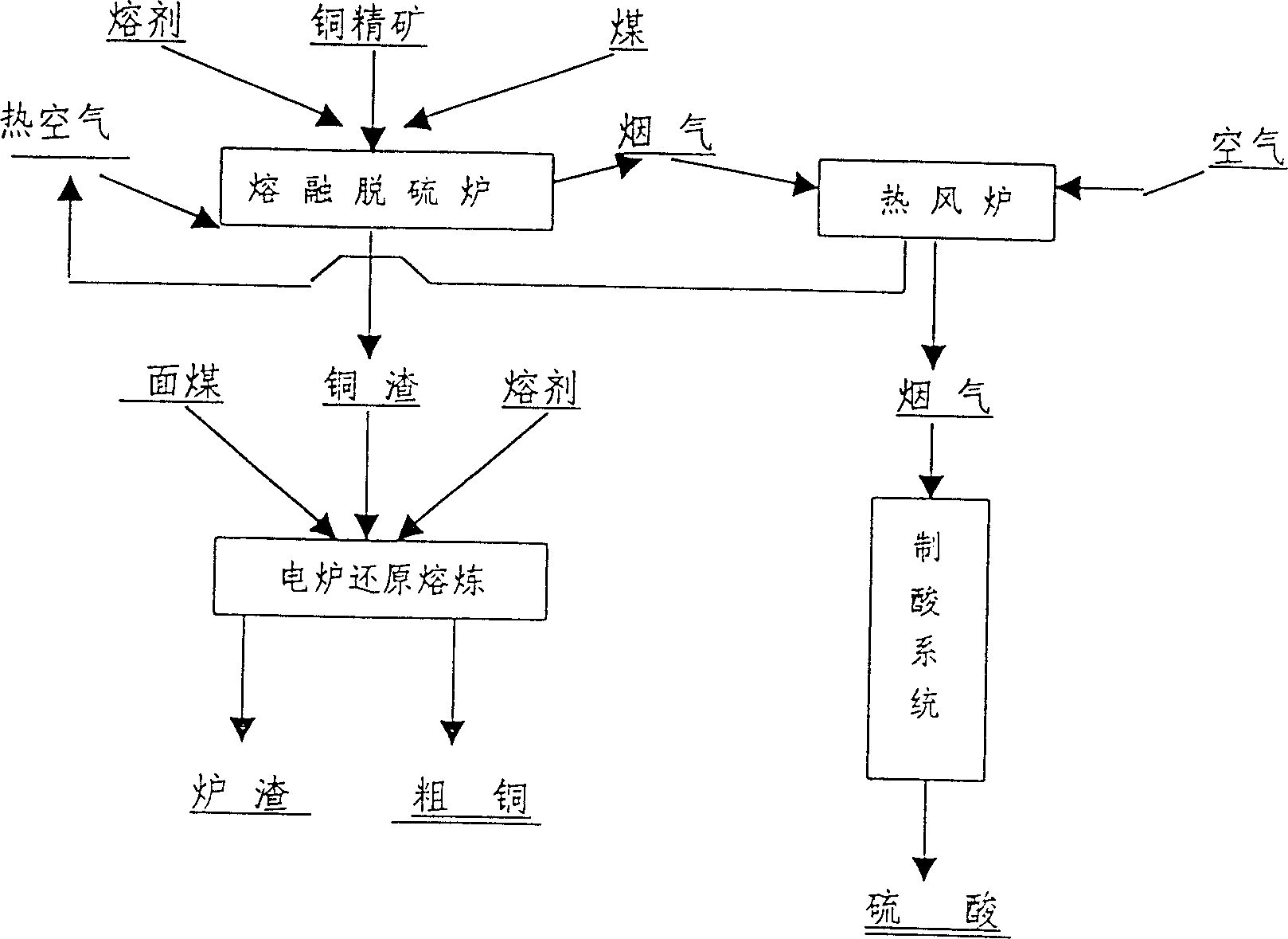

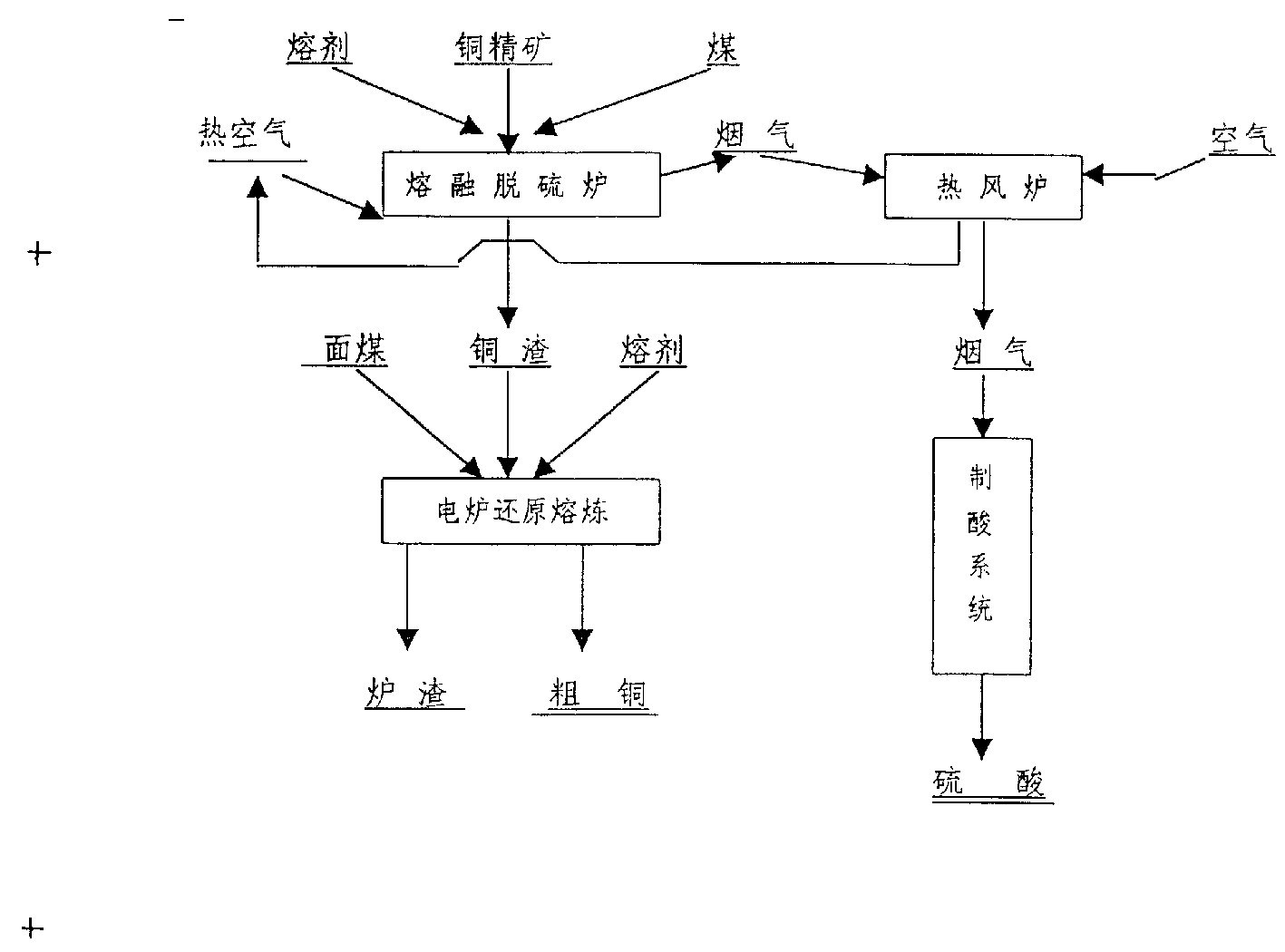

Copper smelting method

A technology of copper smelting and blister copper, which is applied in the field of copper smelting to achieve the effects of saving investment, low slagging rate and benefiting acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add lime to the copper concentrate according to the CaO / Fe ratio of 0.27, add 3% of the total weight of coal, control the temperature of the melt at 1200°C, and blow in air for melting desulfurization. A molten desulfurization slag containing 26.1% Cu and 0.01% S was obtained with a yield of 81% (relative to copper concentrate). The desulfurization rate is 99.9%.

[0019] Cu

Embodiment 2

[0022] According to the CaO / Fe ratio of 0.36, add limestone to the copper concentrate, add 4% of the total weight of coal, control the temperature of the melt at 1180°C, and blow in air for melting desulfurization. A molten desulfurization slag with a yield of 85% (relative to copper concentrate) and a content of S0.07% was obtained. The desulfurization rate is 99%.

[0023] Cu

Embodiment 3

[0026] Add lime to the copper concentrate according to the CaO / Fe ratio of 0.25, add 5% of the total weight of coal, control the temperature of the melt at 1250°C, and blow in air for melting desulfurization.

[0027] Cu

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com