Method for controlling water-turbine of water pump

A technology of water pump turbine and flow controller, which is applied in the direction of controlling generators, control systems, mechanical equipment, etc., can solve problems such as insufficient guarantee of operation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Some preferred embodiments of the present invention will be explained below with reference to the accompanying drawings.

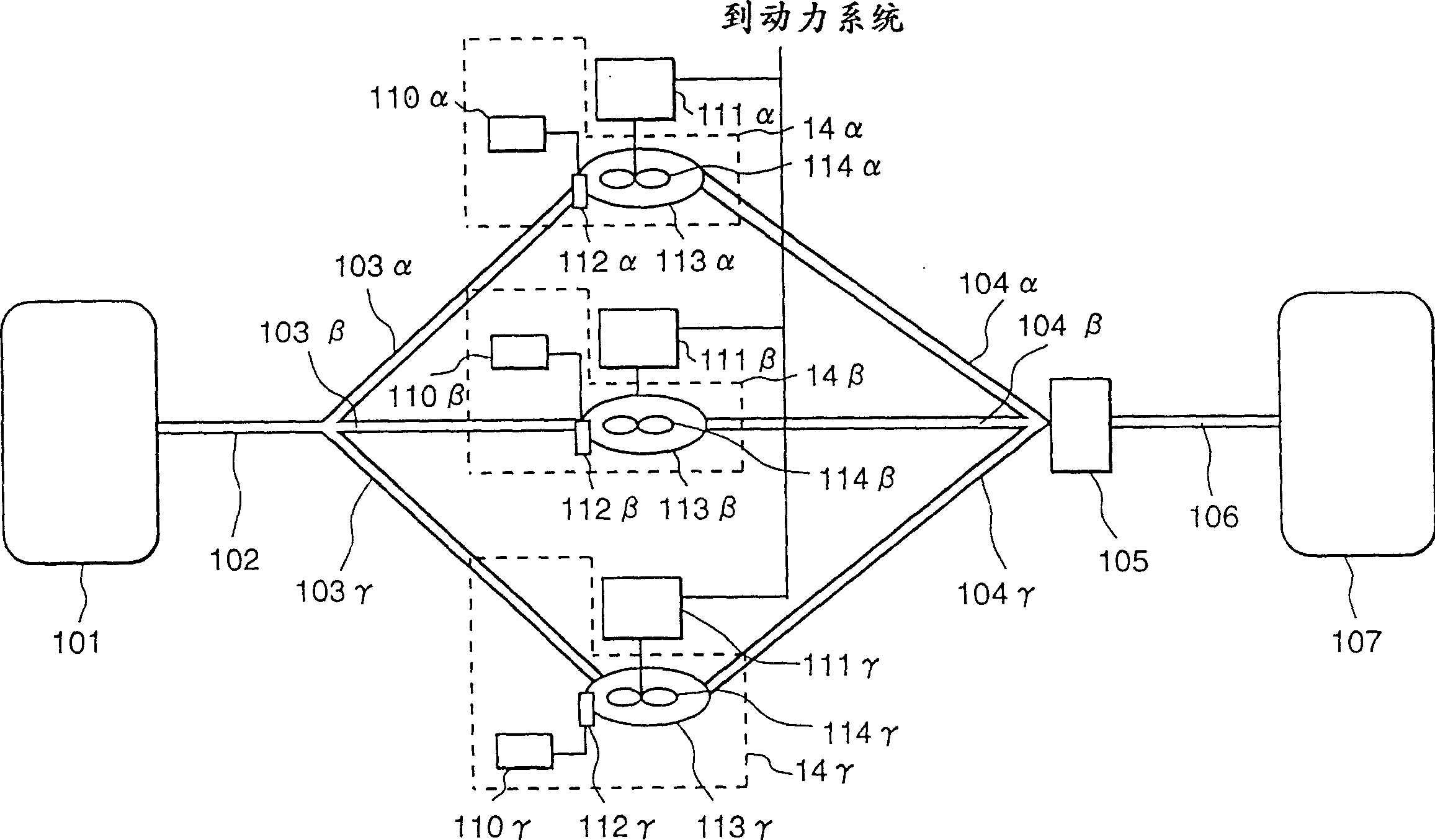

[0074] see below figure 2 The overall structure of the pump turbine of the present invention will be explained. The water collected in the upper reservoir 101 is introduced into the draft pipe 102, and then divided into the water pump turbines 14α-14γ by the draft pipes 103α-103γ, respectively.

[0075]The amount of water flowing from the guide pipes 103α-103γ into the impellers 114α-114γ of the pump turbines 14α-14γ is controlled by the guide valves 112α-112γ, and these guide valves are respectively controlled by the regulating devices 110α-110γ. The power of the swooping water makes the impellers 114α-114γ rotate, and the power of the impellers is transmitted to the generators 111α-111γ. The electricity generated by the generator is delivered to the power system.

[0076] The water flowing through the pump turbines 14α-14γ is introduced into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com