Method and device for determining hydralic pitch K value of propeller hydrodynamometer

A flow meter and paddle technology, which is applied in the field of measuring the blade hydraulic pitch of a general-purpose plastic blade propeller flow meter, can solve the problems of high daily operation and maintenance costs, low efficiency of production verification of flow meters, and complicated operating procedures, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

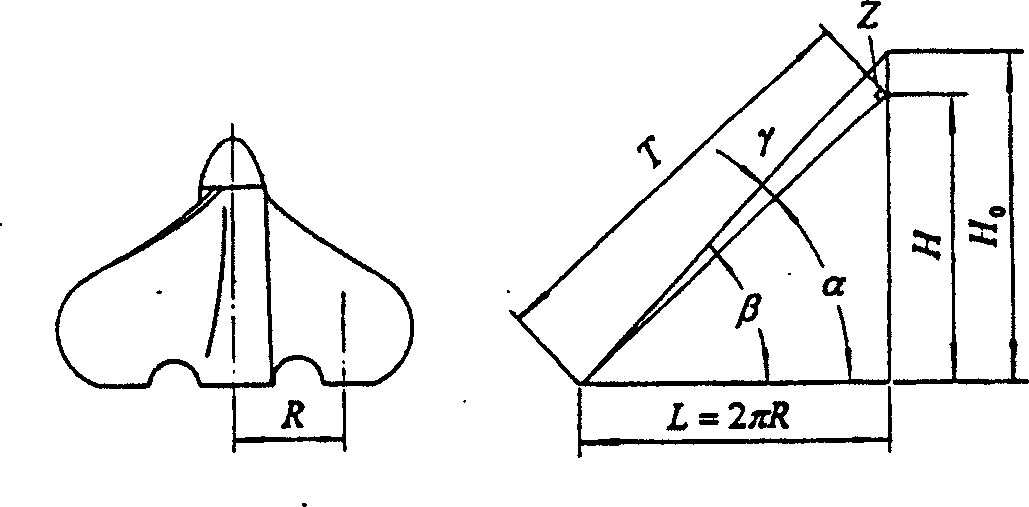

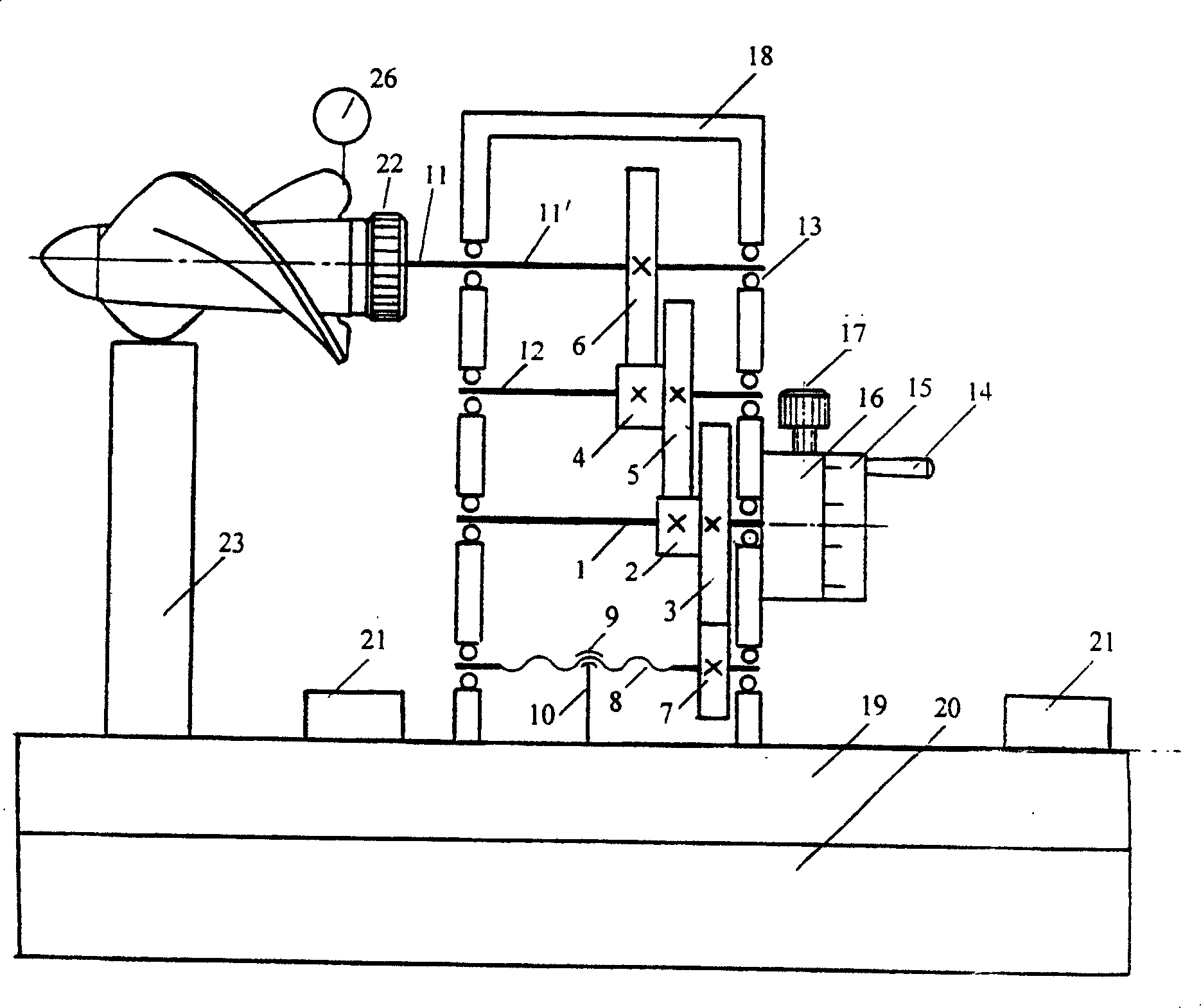

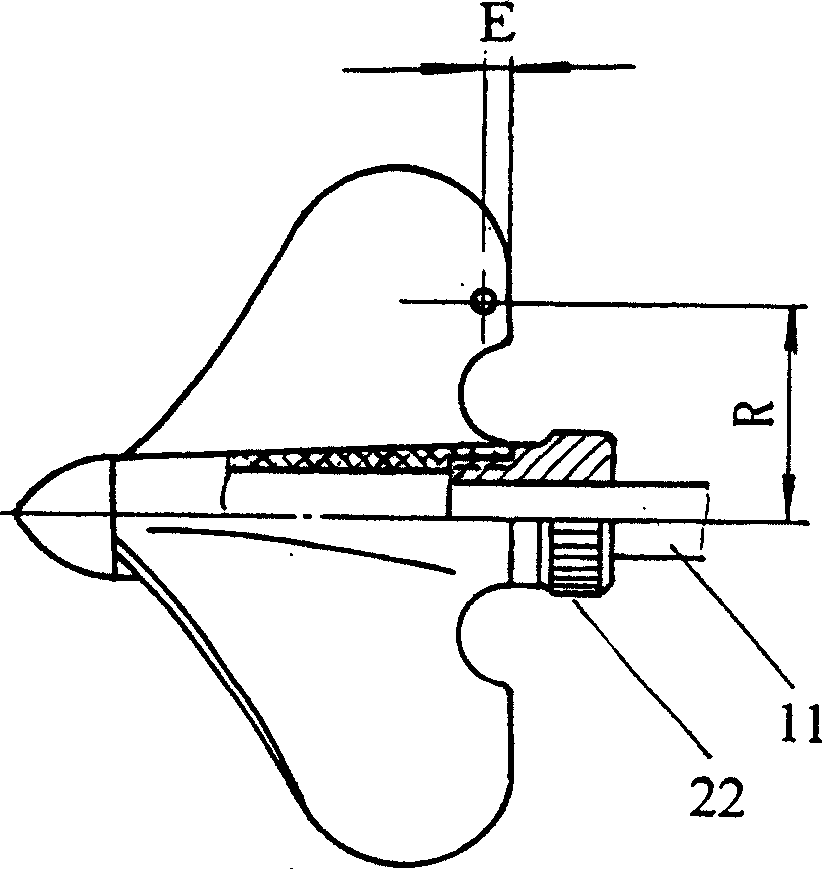

[0095] Embodiment 1, with reference to figure 1 : The analysis diagram of the calculation principle of the blade mechanical pitch shown in the figure is image 3 .4 Helix development at the measuring radius R of the blade. The following is a commonly used plastic blade propeller current meter product, and 244 instruments are sampled in mass production as a non-limiting example: it is known that the blade radius of rotation of the propeller current meter R=59.8mm, and the blade mechanical pitch upper limit H 0 =250mm. figure 2 It is the components and parts of the blade mechanical pitch measuring equipment: variable speed transmission mechanism - driving shaft 1, driving gear A 2, driving gear B 3, driven gear A 4, driven gear B 5, output gear 6, rear gear 7. Thread screw 8, nut 9, nut fixing block 10, driven gear shaft 11', driven shaft 12, bearing 13; control device - handle 14, dial 15, reading pointer disc 16, knurled brake Screw 17; linear movement mechanism - chassis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com