Combined high-effective wet desulfurization dust-removing equipment

A wet desulfurization and combined technology, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve problems such as corrosion of induced draft fans and chimneys, one-time use of desulfurized water, and overload of induced draft fans, etc., and achieve flue gas circulation The effect of small resistance, avoiding secondary pollution and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

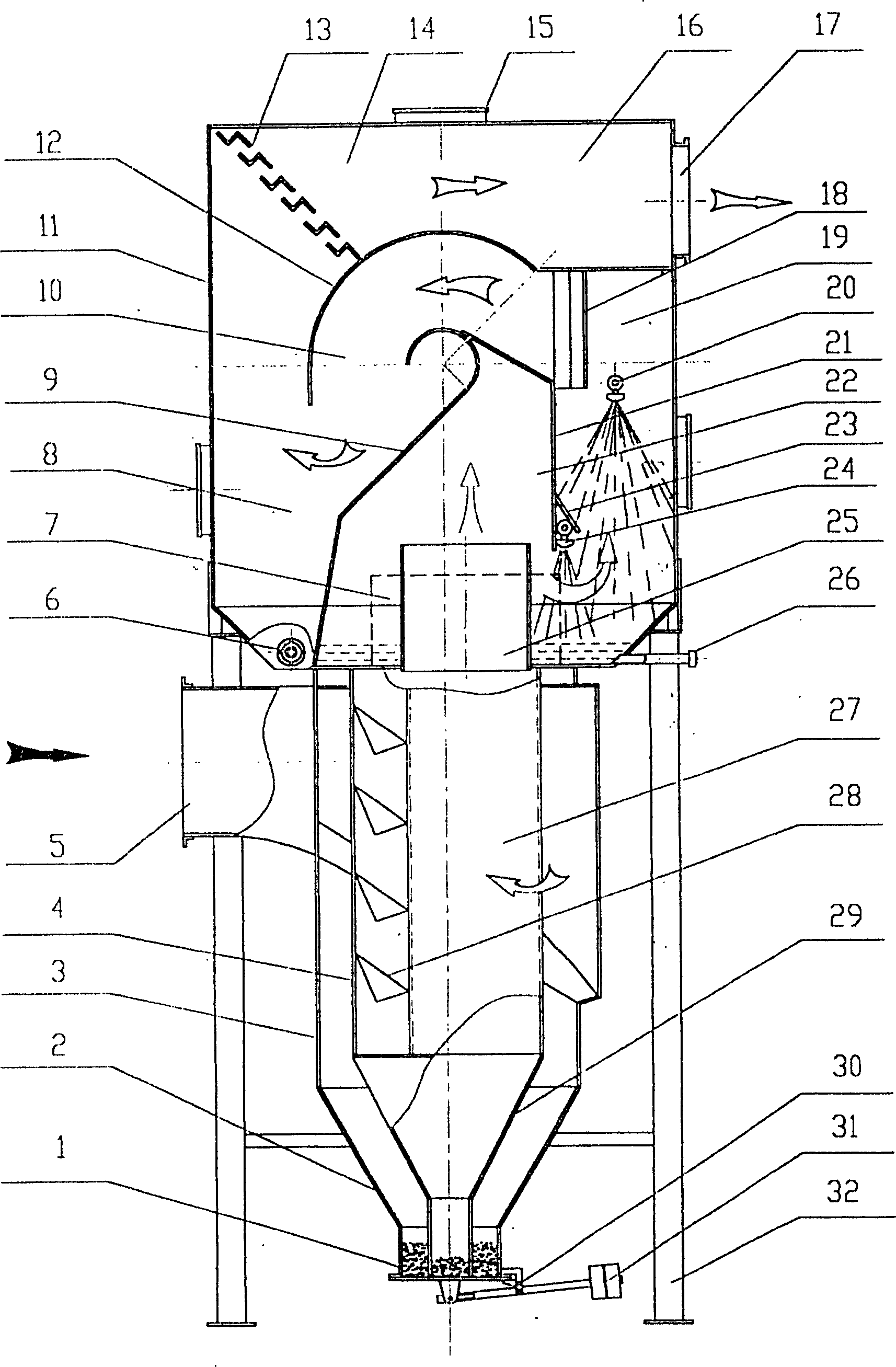

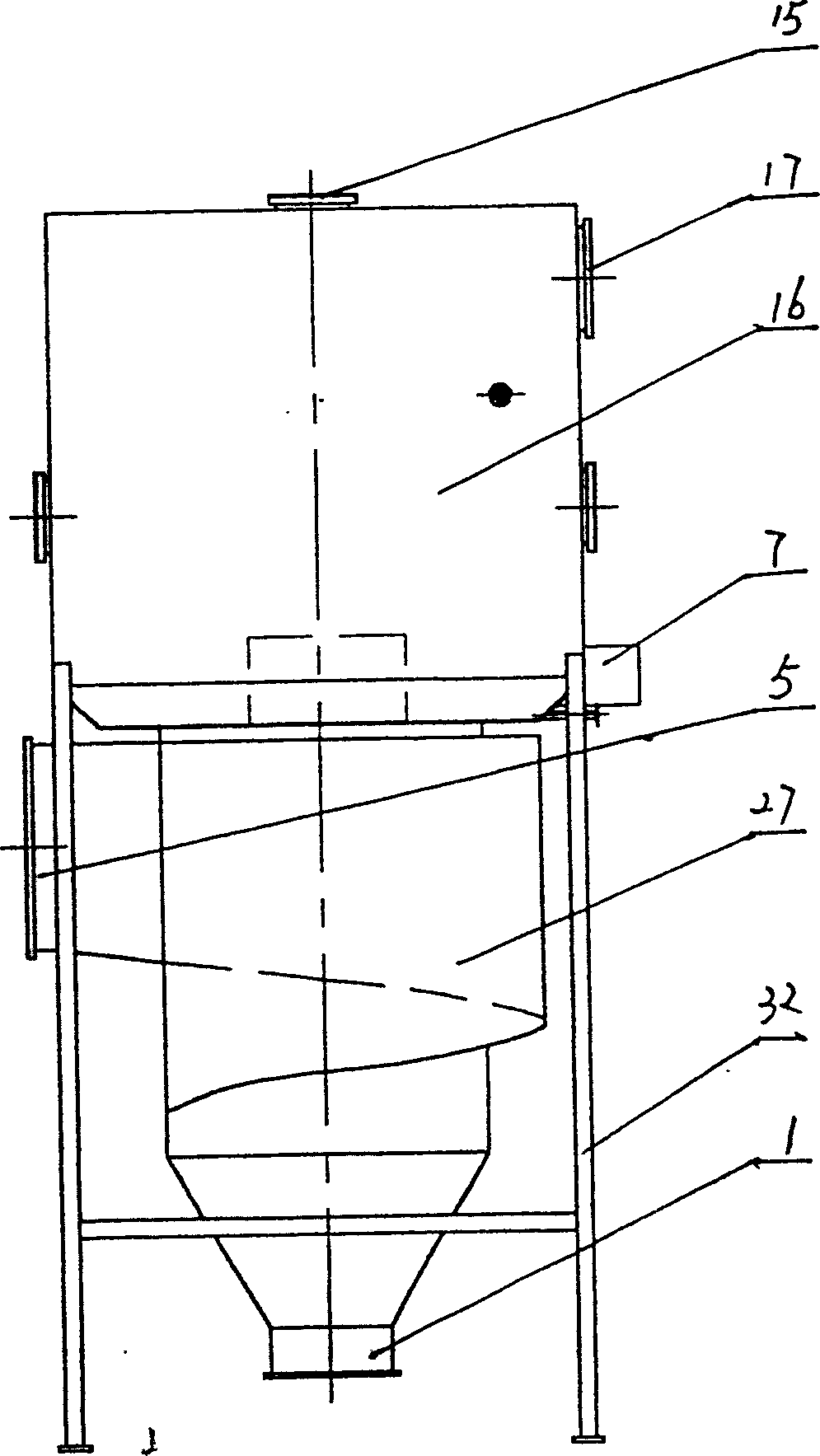

[0023] Example 1, see figure 1 , 2 4. Weld the lower outer cyclone body 3 and the lower inner cyclone body 4 with steel, install the flue gas inlet 5 fixedly on one side of the lower outer cyclone body 3, and weld the guide vanes 28 on the outer wall side of the lower inner cyclone body 4. , the lower outer cyclone body 3 and the lower inner cyclone body 4 are welded together, the inner ash discharge cylinder 29 and the outer ash discharge cylinder 2 are respectively fixed and installed at the lower part, and the ash discharge device 1 is fixedly installed at the bottom of the ash discharge device 1. The ash placing device 30 is movably installed at the opening of the ashtray, the ash placing device 30 is connected with the counterweight iron 31 through the connecting rod, the ash placing device 30 is controlled by the weight of the counterweight iron 31 itself, and an ash pit is arranged below the corresponding ash placing device 30 36. The side wall of the ash pit 36 clos...

Embodiment 2

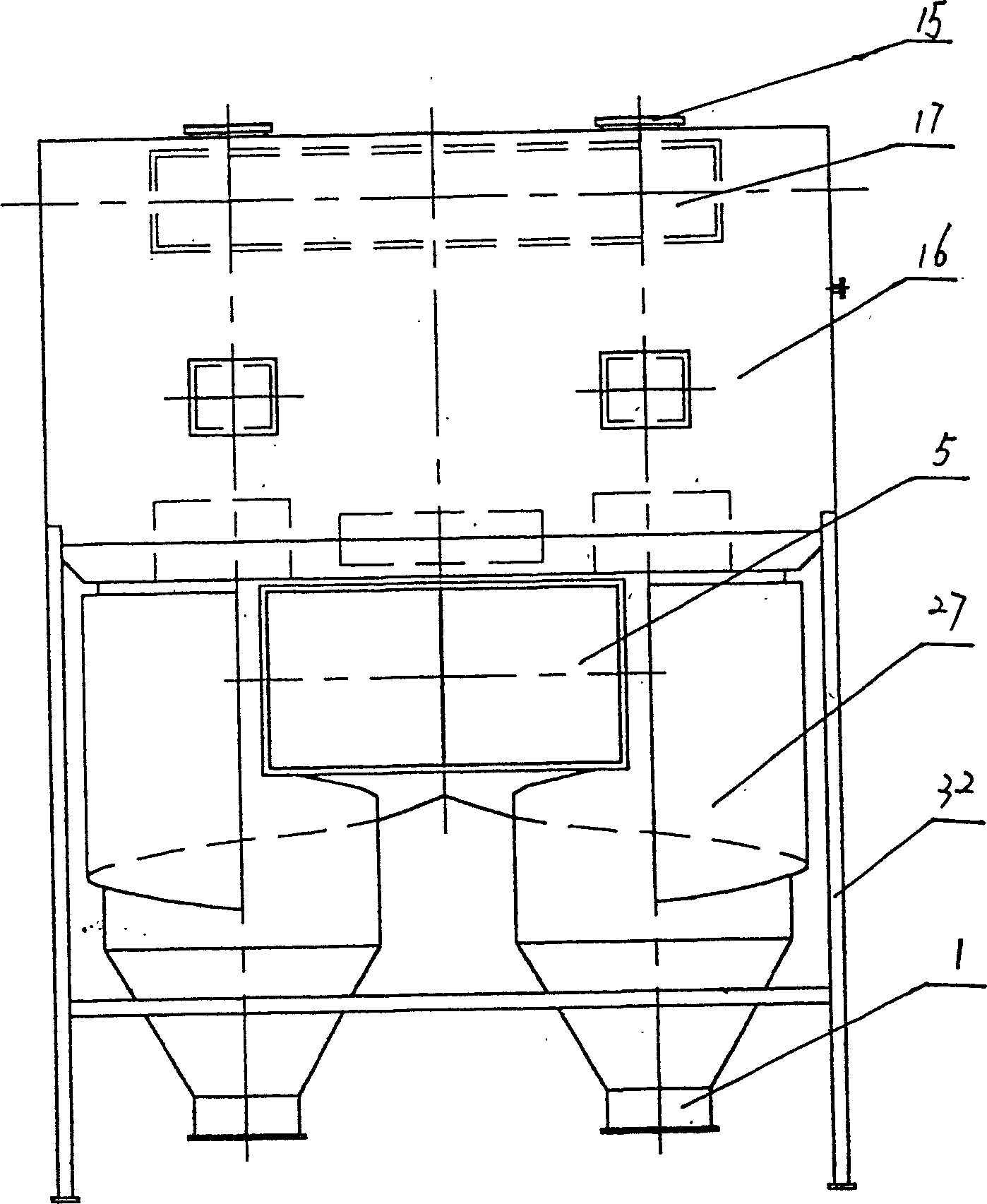

[0024] Example 2, see image 3 , Same as Embodiment 1, the lower dry cyclone dust removal device 27 of the combined high-efficiency wet desulfurization dust collector of the present invention may be one or multiple.

[0025]The combined high-efficiency wet desulfurization and precipitator of the present invention, when in use, the dust-laden flue gas or sulfide discharged from the boiler enters the flue gas inlet of the combined high-efficiency wet desulfurization and precipitator, and the lower dry precipitator first removes 90% of the flue gas from the flue gas. After the coarse dust above % is removed, the flue gas enters the flue gas diffusion chamber in the upper wet desulfurization dust collector through the spiral straight pipe at a speed of 8-22m / s, and the dust-containing and sulfide gas flow directly impacts the liquid surface, causing a large number of vortexes. The large dust particles fall into the water at the bottom of the pool, and the flue gas and tiny dust pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com